Salt air does not forgive weak hardware. A phone that looks “industrial” can rust, leak, or lose audio after one season on deck.

Yes, explosion-proof telephones can be suitable for marine environments when the build targets offshore corrosion, water ingress, vibration, UV, and proper cabling, not only Ex certification.

Offshore suitability is a whole-stack requirement

Marine “fit” is not a single certificate

An explosion-proof label tells one story. It tells ignition safety in hazardous zones. Marine suitability tells a different story. It covers salt, sun, deck vibration, wash-down, and long-term corrosion at every seam and fastener. A device can be IECEx/ATEX-ready and still fail on a vessel if the cable gland corrodes or the keypad hardens under UV.

A good offshore decision starts with three questions:

1) What is the mounting zone: open deck, sheltered deck, process module, or indoor control room?

2) What is the daily exposure: hose-down water jets, salt fog, fuel mist, or cleaning chemicals?

3) What is the operating duty: emergency calls, hotline, paging, or normal operations?

These answers decide the target stack: IP rating, impact resistance, corrosion class, vibration and shock profile, and cable and gland specification.

The “minimum set” that usually works offshore

For most offshore platforms, FPSOs, and coastal vessels, the minimum set looks like this:

-

IP66 or IP67 for wash-down and spray

-

IK10 for impact and rough handling

-

Corrosion-ready materials like 316L stainless or marine-grade GRP

-

salt spray testing 1 evidence for the external build

-

UV-aging evidence for anything exposed to sun

-

Marine-grade cabling and glands that keep IP and shielding intact

| Offshore risk | What it breaks first | What the phone must prove |

|---|---|---|

| Salt fog | Fasteners, glands, paint edges | Corrosion test evidence and material list |

| Wash-down | Seams, keypad perimeter | IP66/67 pass with correct assembly |

| Vibration | PCB joints, hook switch, connectors | IEC 60068 vibration and shock performance |

| UV | keypad, plastics, labels | UV aging test and UV-stable materials |

| EMI/EMC | Ethernet link, SIP stability, audio | Shield bonding plan and grounding |

What “suitable” means in real procurement terms

A phone is “marine suitable” when the vendor can show test reports and a stable bill of materials that matches what ships. The report should not only say “PASS.” It should list:

-

enclosure material grade and surface finish

-

fastener grade and gland material

-

gasket compound type for salt and oils

-

corrosion and UV results

-

vibration and shock results

-

cable and shielding termination guidance

This approach makes offshore projects smoother because classification teams, EPC teams, and maintenance teams all look at the same evidence. It also stops the most common failure: a strong enclosure paired with weak accessories.

The next sections break this into simple parts that can be copied into a ship deck or platform specification.

If the plan is clear, the phone becomes predictable. That is the real goal offshore.

Which certifications and materials ensure offshore suitability?

Marine buyers often see many labels on a datasheet. The risk is picking labels that do not match the real exposure on deck.

Offshore suitability is strongest when an Ex telephone also meets IP66/67, IK10, and a marine corrosion approach like 316L or GRP, and when NEMA 4X is used as a corrosion-focused enclosure target.

Ratings that matter on deck

For offshore use, these ratings carry real value:

-

IP66: dust-tight and resistant to strong water jets

-

IP67: dust-tight and resistant to temporary immersion

-

IK10: high impact resistance for hard knocks and rough handling

-

NEMA 4X: wash-down protection plus corrosion resistance intent, often used in North American specs

These are not replacements for Ex approvals. They sit beside Ex approvals and protect day-to-day uptime.

Materials that survive salt and cleaning

The enclosure is the first line of defense, but it is not the only one.

316L is a common offshore choice because it resists corrosion better than many standard steels. It also holds mechanical strength and thread integrity. That helps keep gaskets compressed and glands tight after years of maintenance.

GRP can be very strong offshore because it does not rust. It also avoids some galvanic issues. Still, GRP quality depends on resin system, wall thickness, and UV strategy. A GRP phone should prove UV stability and long-term sealing compression.

Powder-coated aluminum

Powder-coated aluminum can work in sheltered areas, but open deck use needs strict coating control. Edges, scratches, and hardware interfaces are the common weak points. If aluminum is used, a strong coating system and proper edge design are non-negotiable.

Do not forget fasteners, labels, and seals

Offshore failures often start at small parts:

-

fasteners seize or rust stain

-

labels fade under UV and chemical cleaning

-

keypad materials harden or swell

-

gasket compounds relax and lose compression

| Part | Offshore best practice | Why it matters offshore |

|---|---|---|

| External fasteners | Marine-grade stainless matched to housing | Prevents rust lock and cover damage |

| Gaskets | Oil/salt resistant compound with low compression set | Preserves IP over years |

| Keypad and handset | UV-stable elastomer and inks | Keeps usability in sun and salt |

| Bonding points | Protected, low-impedance bonding surfaces | Controls corrosion and EMC behavior |

In OEM and ODM projects, one small change can break offshore suitability. A new keypad supplier can change the elastomer compound. A new gland can change galvanic behavior. That is why offshore specs should lock key materials and require re-test when critical parts change.

Do salt spray and corrosion tests meet ISO 9227/ASTM B117 hours for coastal platforms and vessels?

Many tenders ask for “1000 hours” as a single line. That can help, but only when the evaluation method and sample build are clear.

Salt spray hours under ISO 9227 or ASTM B117 are useful screening evidence, but offshore specs should also demand cyclic corrosion, scribed-panel evaluation, and a material and coating report that matches the exact phone build.

What salt spray really proves

Salt spray tests expose samples to a controlled salt fog. The test helps compare coatings and materials. It also helps detect pores, weak edges, and coating defects. Still, salt spray is not a direct life predictor. Offshore corrosion is often wet-dry cycling, with sun and salt crystals, plus mechanical wear.

That is why a good offshore requirement uses salt spray as a baseline, then adds cyclic testing when the phone sits on open deck.

Writing the “hours” line in a way that is enforceable

Offshore buyers often ask for:

-

≥1,000 hours for coastal platforms

-

1,500–2,000 hours for open deck or harsh coastal zones

Those numbers only make sense with pass limits. A strong spec should include:

-

scribe requirement on coated samples

-

rust creep limit from the scribe

-

blistering and delamination limits

-

photo evidence and lab report details

| Corrosion evidence item | What to specify | What it prevents |

|---|---|---|

| Standard | ISO 9227 or ASTM B117 | Avoids “in-house method” confusion |

| Exposure hours | ≥1,000–2,000 h (zone dependent) | Sets a clear baseline target |

| Evaluation | Scribe + rust creep limit + blister rating | Stops weak coatings from “passing” |

| Sample definition | As-built enclosure, fasteners, glands | Stops “coupon only” shortcuts |

Add ISO 12944 language for offshore clarity

Coating and corrosion categories help align with offshore expectations. Many offshore specs reference harsh classes like C5 or CX to express atmospheric severity. This helps the coating system design match the site.

A practical approach is to state:

-

the intended zone (open deck, sheltered deck, indoor)

-

the corrosivity class target for exposed metal surfaces

-

the coating system type and minimum dry film thickness range

-

evidence of salt spray and cyclic corrosion

Make chemical compatibility part of the corrosion package

Offshore phones also see diesel mist, hydraulic oils, and strong cleaners. If the gasket swells, IP fails even if the metal looks perfect. If the cable jacket softens, the gland seal fails. So the corrosion package should include chemical compatibility notes for:

-

gasket compounds

-

cable jacket

-

keypad materials

-

paint or coating system

Offshore approval goes faster when the vendor delivers one “corrosion dossier” with test hours, evaluation rules, and a material list that matches the exact product configuration.

How do vibration, shock, and UV ratings support ship decks, FPSOs, and wind farms?

A phone can pass corrosion tests and still fail on a vessel if vibration loosens glands or cracks solder joints.

Marine suitability improves when the phone is validated to IEC 60068 vibration and shock methods and when UV stability is verified for exposed plastics, seals, labels, and coatings.

Vibration and shock are daily stress offshore

Ship decks and FPSOs have constant vibration from engines, generators, pumps, and waves. Wind farms add tower vibration and strong wind-driven motion. These stresses can cause:

-

connector fretting and intermittent link drops

-

loose fasteners and gland relaxation

-

microphone or speaker wiring fatigue

-

small cracks in solder joints over long time

A good test plan uses environmental testing standards 5:

-

sinusoidal vibration for sweeping resonances

-

random vibration for real-world broadband stress

-

shock testing for knocks and handling impacts

The spec should define severity, axis, duration, and functional monitoring during the test. A phone that stays registered and keeps audio stable during vibration testing is far more trustworthy on a live deck.

UV exposure is a real failure driver

UV does not only fade color. It can harden seals, crack plastics, and make keypads sticky or brittle. Labels can become unreadable. That matters for emergency instructions and hotline keys.

UV evidence is strongest when it includes:

-

UV aging exposure method for plastics and coatings

-

before and after checks for cracking, chalking, and key feel

-

label legibility checks after exposure and cleaning

| Exposure type | What it attacks | What the phone should prove |

|---|---|---|

| Vibration | joints, connectors, glands | No loose parts, stable calls, stable PoE link |

| Shock | mount points, handset cradle | No cracks, no stuck hook switch |

| UV | keypad, gaskets, labels, coatings | No cracking, no severe hardening, readable labels |

Small design choices that improve marine robustness

Some hardware choices help a lot offshore:

-

anti-loosening fastener strategy that still respects Ex maintenance rules

-

strain relief and cable routing that reduces pull on glands

-

potting or mechanical support for heavy components on the PCB

-

thicker front plates or reinforced GRP ribs to keep seal compression stable

When the vibration and UV plan is clear, the phone behaves like a marine device, not only an industrial one.

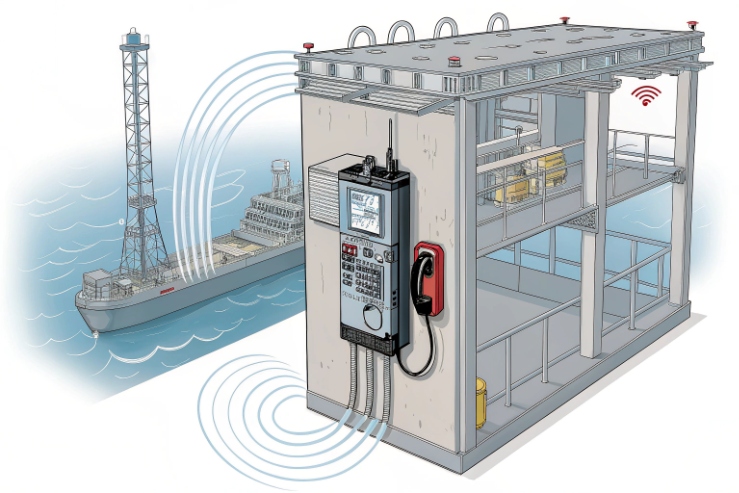

What cabling and glands are recommended—armored Ethernet, marine-grade glands, and EMC grounding for PoE?

Many offshore phone problems are not inside the phone. They start at the cable entry and the shield termination.

Use marine-grade shielded Ethernet with the right jacket, pair it with Ex-rated marine glands, and apply a clear EMC bonding plan for PoE that keeps 360° shield termination and stable equipotential grounding.

Cable selection for offshore PoE phones

A marine Ethernet choice should match the route and exposure:

-

Shielded Cat5e/Cat6/Cat6A for EMC control and stable PoE

-

UV-resistant, oil-resistant jacket for exposed runs

-

low smoke zero halogen 6 where required by vessel rules

-

Armored Ethernet where mechanical damage risk is high, like cable trays near work areas

-

Tinned copper braid or foil shield to reduce corrosion in the shield path

If the cable crosses zones with high EMI, shield quality and termination style matter more than category rating.

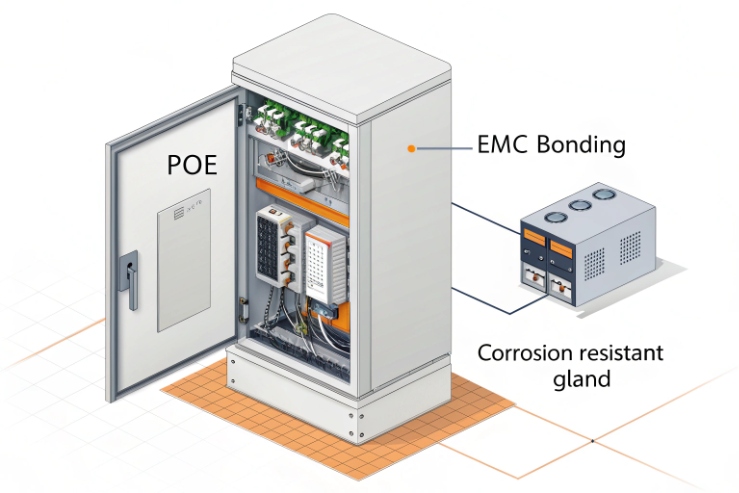

Glands: match metal, match thread, match chemistry

Cable glands are the most common leak point offshore. A good gland choice includes:

-

hazardous area certification 7 suitable for the hazardous zone

-

IP rating that matches the phone target

-

marine-grade materials like 316L stainless or suitable nickel-plated brass when allowed

-

seals compatible with oils, fuels, and cleaners used on the deck

-

an EMC gland option when shield bonding at the entry is needed

The gland should also match the cable construction. An armored cable needs an armored gland system. A soft jacket needs proper compression control. A wrong match causes slip and leaks.

| Installation item | Recommended approach | What it prevents |

|---|---|---|

| Ethernet cable | Shielded, marine jacket, armored when needed | EMI issues and jacket cracking |

| Gland material | 316L or marine-grade option | Corrosion, seized threads |

| Shield termination | 360° termination at gland or EMC clamp | High-frequency noise ingress |

| Bonding | Equipotential bonding to local earth | Touch voltage differences and EMI problems |

| PoE surge | SPD strategy when runs are exposed | Port damage and random resets |

EMC grounding for PoE: keep it simple and consistent

PoE phones behave best when the shield and bonding plan is consistent end-to-end.

-

Keep the cable shield continuous.

-

Use 360° terminations where the design supports it.

-

Bond the enclosure to the local bonding network.

-

Avoid floating metal parts that can build charge and then discharge into the electronics.

If the project needs a special bonding strategy due to ship grounding rules, it should be written once and applied everywhere. Mixed practices cause the worst issues: random link drops, audio pops, and hard-to-repeat resets.

A short offshore cabling note that works in RFQs

A clean RFQ note can say:

- “Provide shielded marine-grade Ethernet suitable for UV and oil exposure, with Ex-rated marine glands and 360° shield termination. Provide bonding and EMC installation guidance for PoE.”

This one line prevents many hidden failures because it forces the supplier and installer to treat cabling as part of the product behavior.

Conclusion

Explosion-proof telephones can fit marine use when the full stack is offshore-ready: corrosion proof build, IP66/67, IK10, proven vibration and UV stability, and marine-grade shielded cabling with correct glands and bonding.

-

Standardized corrosion testing method essential for validating material durability in harsh marine environments. ↩ ↩

-

Classification system defining the protection levels provided by electrical enclosures against dust and water. ↩ ↩

-

High-grade austenitic steel providing superior resistance to chlorides and salt-driven corrosion offshore. ↩ ↩

-

Composite material ideal for marine structures due to its high strength-to-weight ratio and corrosion immunity. ↩ ↩

-

International standards defining procedures for assessing the performance of electronic components under extreme environmental conditions. ↩ ↩

-

Material standard for cable jackets that minimizes toxic gas emission during fire events on ships. ↩ ↩

-

Global scheme ensuring that equipment for explosive atmospheres meets international safety and operational standards. ↩ ↩