Outdoor phones that work in summer can die in winter. Cold-start failures and heat-soak shutdowns create silent emergency points.

Most industrial weatherproof telephones are specified for -20 to +60°C, while harsh-site models target -40 to +70°C. The right range is the one proven by cold-start and heat-soak tests on a powered unit with PoE load applied.

How temperature limits are defined in real projects

Operating temperature is not one number. It is a set of conditions that must be clear in the tender, the test plan, and the site acceptance checklist. Many buyers only write “-40 to +70°C” and move on. That leaves gaps. A phone can survive storage at -40°C but fail to boot at -25°C. A phone can run at +70°C in a lab chamber but overheat in direct sun because solar load adds extra heat. A phone can pass at +70°C with no PoE load 1 but reboot when the camera module, IR LEDs, or high-power speaker is active.

Since 2010, projects seen at DJSlink show the same pattern: the best temperature spec is the one tied to a clear test method and a clear use case. A weatherproof telephone 2 is also a thermal system. The enclosure, gasket, membrane vents, cable glands, and even the mounting surface change how heat moves. The network and power method matter too. PoE power becomes heat inside the box. If the site uses long cable runs, the device may see lower voltage and higher current, which raises internal loss.

Key terms that should be separated in your datasheet

| Term | What it means | Why it matters for weatherproof phones |

|---|---|---|

| Operating range | Device works within specs while powered | This is what clients care about |

| Cold-start range | Device can boot and register after cold soak | Stops “works only if already warm” failures |

| Storage range | Device survives unpowered | Not enough for emergency phones |

| Duty cycle | Which features are active (speaker, camera, IR) | Power draw changes internal heat |

| Solar load | Extra heating from sunlight | A big gap between lab and outdoor poles |

| Condensation risk | Moisture inside during thermal swings | Impacts audio and corrosion |

A clean temperature spec is the foundation. Next comes verification, because the words “-40 to +70°C” are only useful when cold-start is proven.

If the buyer wants confidence, the tender must force cold-start proof, not only “survival.”

Does the device meet -40 to +70°C operation with cold-start performance verified?

A phone can claim -40°C and still fail in the field. If it cannot boot, register, and place a call after a cold soak, the number is just ink.

To claim -40 to +70°C operation, cold-start must be tested after a full soak at -40°C, then power-on must prove boot, SIP registration, audio, and I/O functions under real PoE load.

What “cold-start verified” should mean

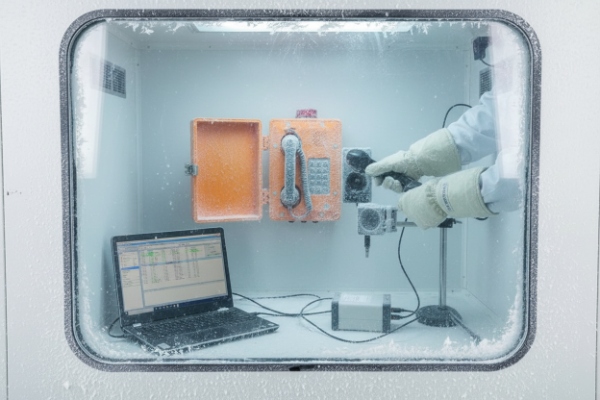

Cold-start verification is simple to describe and strict to execute:

-

The unit stays unpowered in a chamber at the target low temperature until it is fully soaked.

-

The unit is then powered on at that temperature.

-

The unit must boot, register, and complete a call with acceptable audio.

-

If there are buttons, keypad, or hook-switch functions, they must work.

-

If there is a camera, IR, or beacon, it must run as defined in the duty cycle.

Many teams test “already-on” operation at low temperature. That is easier. It is also not enough for many outdoor sites. Power outages happen. Switch ports reboot. Maintenance disconnects cables. A true emergency device must recover in the cold, not only survive while already warm.

A practical cold-start test plan that fits tenders

A good baseline plan uses three parts:

1) Cold soak

Soak time should be long enough for the internal mass to stabilize. For metal enclosures, that can be several hours. The goal is stable internal temperature, not a quick air reading.

2) Power-on and functional checks

Boot time, SIP registration 3 time, call setup, two-way audio level, DTMF or call button action, relay I/O, and indicator LEDs should be verified.

3) Repeat cycles

One pass is not confidence. Repeating cold-start cycles finds marginal parts like LCDs, keypads, speaker diaphragms, and cable seals that stiffen.

What commonly fails first at -40°C

-

Rubber parts stiffen. Keypads and handset cords get hard.

-

Plastic clips and thin housings become brittle.

-

Speaker response drops and mic sensitivity shifts.

-

LCD response time becomes slow, or displays fade.

-

Cable jackets shrink and strain the gland seal.

-

Condensation becomes ice in hidden cavities.

How to write the requirement so vendors cannot dodge it

| Tender item | Recommended wording | Why it prevents weak claims |

|---|---|---|

| Cold-start | “Power-on at -40°C after full soak; must register and complete calls” | Stops “operates if pre-heated” claims |

| Load | “Test with PoE power and full feature duty cycle” | Stops no-load testing |

| Pass/fail | “No reboot, no audio failure, no keypad sticking” | Keeps the test tied to real use |

| Evidence | “Provide test report and configuration list” | Makes comparisons fair |

A short story often helps clients: a device can be rated to -40°C for storage, yet the internal oscillator or keypad fails to behave until -20°C. Cold-start testing reveals that gap immediately.

After cold-start is clear, the next question is how to handle sub-zero operation day after day. Some sites need heaters or dehumidifying strategies. Other sites want batteryless designs for reliability.

Are heaters, dehumidifiers, and batteryless designs specified for sub-zero conditions?

Sub-zero problems are not only boot issues. They are also humidity and condensation issues. Then corrosion grows, and audio ports clog.

Heaters are useful when condensation and ice can block audio paths, while dehumidifying and vent strategies help avoid fogging. Batteryless designs can improve reliability, but upstream power backup is still needed for emergency availability.

When heaters make sense

A heater is not a default feature. It is a tool for a specific risk:

-

Ice forms at the mic/speaker grill.

-

Snow melt refreezes on the handset cradle.

-

Condensation freezes inside the acoustic cavity.

-

Displays or cameras need minimum temperature to respond.

A small heater can stabilize internal conditions, but it increases power draw. That matters for PoE budgets and long cable runs. If the heater is always on, internal heat rises and can shorten life at moderate ambient temperatures. So heater control should be tied to a thermostat, and the duty cycle should be defined in the datasheet.

Dehumidifiers vs vents: the practical approach

In outdoor enclosures, “dehumidifier” often means one of these:

-

a desiccant pack 4 for shipping and early life

-

a breathable membrane vent that reduces pressure pumping

-

conformal coating or sealed modules to tolerate some moisture

For weatherproof telephones, a controlled vent path often reduces long-term condensation. Without a vent, pressure cycles can pull moist air through weak points like keypads and cord entries. A vent must be placed away from direct jets and pooling water.

Batteryless design: why it is popular for harsh sites

Batteryless devices often last longer in extreme cold. Batteries suffer in low temperature. They also add failure modes: swelling, leakage, capacity drop, and charging faults. A batteryless design can be simpler and more stable.

Still, emergency availability is a system decision. If power can fail at the site, the proper solution is usually:

-

UPS on the PoE switch or midspan injector 5

-

protected power for the network path

-

clear supervision and alarms for link loss

What to specify for sub-zero sites

| Sub-zero risk | Design option | What to specify in tenders |

|---|---|---|

| Ice on grills | Heater + grill geometry | Heater control range and max power |

| Condensation | Vent membrane + sealing discipline | Vent placement and IP proof |

| Cold keypad feel | Silicone keypad or glove-friendly design | Actuation force at -40°C |

| Power outages | Batteryless device + upstream UPS | Runtime target at the switch |

A simple message for clients is: heaters and vents protect function, but the system must also protect power. A batteryless phone can be more reliable, but it still depends on PoE and the network.

Now move to high ambient temperatures, because +70°C on paper can fail in the field if the PoE load and enclosure material drive a big internal temperature rise.

How do PoE class and enclosure materials affect thermal derating at high ambient temperatures?

Heat issues look like “random reboots.” Then the site team blames the network. In reality, the phone is protecting itself.

Higher PoE power classes increase internal heat, and enclosure material controls how fast that heat escapes. Metal housings usually spread and reject heat better than plastics, but solar load and mounting method can still force thermal derating.

PoE power becomes heat inside the enclosure

PoE brings power through the cable. The device converts it to internal rails. That conversion is not 100% efficient. The lost energy becomes heat. Also, the functions that use power (high SPL speaker, camera, IR LEDs, beacon lights, relays) also create heat.

At high ambient temperatures, even a small extra heat load can push internal components over their limits. Then the device will:

-

reduce speaker output,

-

limit camera or IR,

-

throttle functions,

-

or reboot if protection triggers.

So thermal design must be tied to the worst case duty cycle. If the tender says “PoE class 0 is enough,” but the real install uses a beacon and loudspeaker at full load, the heat plan is wrong.

Enclosure materials and color matter

Metal housings (aluminum alloy, stainless) usually handle heat better because they conduct and spread heat. Plastic housings can trap heat, especially if air does not circulate. Color matters too. Dark colors absorb more solar heat. A phone rated at +70°C in a chamber can see higher surface temperatures in direct sun.

Mounting matters. A metal backplate bolted to a concrete wall can act as a heat sink. A plastic pole mount can isolate heat and increase internal temperature.

Thermal derating: make it explicit

A good datasheet does not hide derating. It states what happens near the limit:

-

maximum continuous speaker output vs ambient temperature

-

beacon duty cycle vs ambient temperature

-

camera and IR behavior vs ambient temperature

-

PoE class requirement for worst-case mode

What to put in your tender and client proposal

| Thermal factor | What to define | Why it protects your project |

|---|---|---|

| PoE class | “802.3af/at required for full feature set” | Stops under-power installs |

| Worst case load | “Define max speaker + beacon duty cycle” | Avoids surprise reboots |

| Enclosure | “Metal housing preferred for high ambient and solar load” | Improves heat rejection |

| Derating | “Device may reduce output above X°C” | Sets correct expectations |

| Solar | “Test at high ambient with solar simulation or margin” | Bridges lab to outdoor reality |

A client-friendly explanation is simple: power turns into heat, and heat must leave the box. If heat cannot leave, the device protects itself. That is normal behavior, but it must be planned.

Finally, buyers ask which standards validate the temperature claims. The right answer depends on the market and the customer style. Some want IEC methods. Some want MIL-style profiles. Many coastal projects also want salt-fog proof for metals and coatings.

Which standards validate temperature cycling and humidity—IEC 60068, MIL-STD-810, and salt-fog?

A temperature number without a test method is easy to argue about. Standards turn claims into evidence.

IEC 60068 is commonly used for controlled temperature change and humidity tests, while MIL-STD-810 is used for mission-style environmental profiles. Salt-fog is validated using recognized salt mist methods tied to corrosion resistance of materials and coatings.

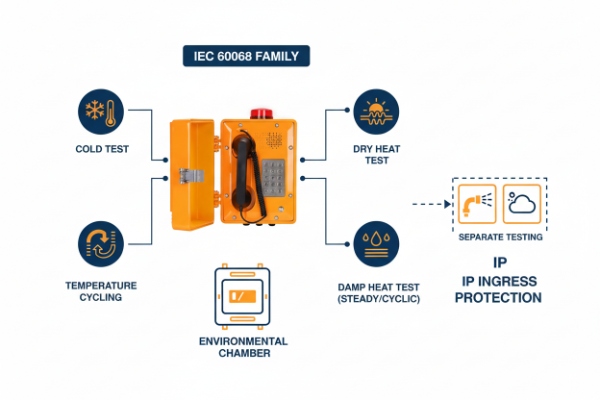

How IEC 60068 is used for weatherproof telephones

IEC 60068 6 is a toolbox of environmental tests. For weatherproof telephones, the most practical grouping is:

-

low temperature operation and storage

-

dry heat operation and storage

-

temperature change / thermal cycling

-

damp heat (steady or cyclic)

-

salt mist for corrosion resistance

The value is repeatability. A lab can run the same method for different suppliers and produce comparable reports. For tenders, it is smart to require that functional checks happen during and after the test, not only visual inspection.

How MIL-STD-810 is used in harsh-site projects

MIL-STD-810 7 is often selected when a customer wants test plans tied to a mission profile. It can be more “use-case driven” than a single fixed condition. This fits projects like transport, defense-linked infrastructure, or rugged industrial deployments.

Still, the same rule applies: define what must work. A phone that “survives” is not enough. It must place calls, pass audio, and keep its seals.

Salt-fog and why it belongs in your tender

Salt-fog 8 is not only about rust. It also impacts:

-

fasteners

-

cable glands and connectors

-

plating quality

-

paint and powder coat quality

-

seam corrosion that lifts gasket lands

A phone can meet IP66 and still fail in coastal air if corrosion destroys the sealing surface. So salt-fog testing, or at least salt-fog-rated materials, is a strong requirement for ports, marine sites, and coastal campuses.

Tender language that makes validation clean

| Requirement area | Example wording | What evidence to request |

|---|---|---|

| Thermal cycling | “Temperature change test per IEC 60068 method; functional checks included” | Lab report + configuration |

| Humidity | “Damp heat steady or cyclic per IEC 60068; no functional degradation” | Report + post-test inspection |

| Low temp | “Cold-start at -40°C after soak; full call tests” | Power-on logs + call records |

| High temp | “Operate at +70°C under full PoE load” | Thermal run log |

| Salt-fog | “Salt mist test per recognized IEC salt mist method for metal parts” | Coating and corrosion report |

A simple message for clients is: IEC gives repeatable methods, MIL gives mission-style profiles, and salt-fog protects coastal reliability. The best project picks the method that matches the customer’s procurement style and the site reality.

Conclusion

A weatherproof telephone’s true temperature range is proven by cold-start, load-based heat tests, and humidity and corrosion validation tied to clear standards 9.

Footnotes

-

Technology delivering DC power and data over Ethernet cabling to remote devices. [↩] ↩

-

Communication device engineered to withstand severe weather and industrial conditions. [↩] ↩

-

Protocol process where a SIP user agent identifies its location to a registrar server. [↩] ↩

-

Moisture-absorbing substance used to maintain dryness in packaging or enclosures. [↩] ↩

-

Device adding PoE power to a non-PoE network link without replacing the switch. [↩] ↩

-

International standard series for environmental testing of electrotechnical products. [↩] ↩

-

US military standard outlining environmental engineering considerations and laboratory tests. [↩] ↩

-

Accelerated corrosion test using salt spray to evaluate protective coatings and materials. [↩] ↩

-

Verification process ensuring equipment meets specified environmental and operational criteria. [↩] ↩