Corrosion can kill a hazardous-area phone faster than any electronics fault. When the handset fails during an emergency, the cost is not only a replacement.

For most offshore and chemical plants, 316L stainless steel is the safest default for an explosion-proof telephone. GRP is best when salt, chemicals, and weight matter most. Powder-coated aluminum can work, but only with proven coating quality and strict accessory control.

How I choose materials for corrosive hazardous sites?

Start with the real corrosion story at the mounting point

Corrosion is not one thing. Offshore decks bring salt spray, wet/dry cycles, and UV. Refineries bring hydrocarbon mist, wash-down, and mixed chemicals from cleaning. Chemical plants can bring acid or alkali vapors that attack coatings and gaskets. Mines can bring conductive dust plus humidity.

So the “best” material depends on what attacks the enclosure every day. A phone on an indoor Zone 1 pump room wall sees a different world than a phone on an open deck near a seawater line.

Separate structure from surface

A phone lasts when its base material and its surface finish both match the site. A strong metal can still fail if the coating blisters. A corrosion-proof composite can still fail if fasteners and glands create galvanic couples or leak paths.

I treat the telephone as five corrosion systems:

-

enclosure body

-

fasteners and brackets

-

cable glands and stopping plugs

-

keypad and hook switch parts

-

gasket and seal compounds

If one system fails, water and salt enter. Then everything accelerates.

Use a life-cycle view, not only a salt-spray number

Salt-spray hours are useful. Still, real sites are cyclic. Wet/dry cycles and UV often drive failure faster than a steady fog test. A good selection also considers:

-

how often the phone will be cleaned

-

who will service it and how often it will be opened

-

how easy it is to restore sealing after service

-

spare parts availability for gaskets, keypads, and cords

| Site condition | Best default material | Why it usually wins | What must still be controlled |

|---|---|---|---|

| Offshore open deck | 316L or GRP | strong corrosion margin | glands, fasteners, grounding |

| Chemical plant with aggressive vapors | GRP or coated 316L | better chemical stability | gasket compound compatibility |

| Refinery outdoor wash-down | 316L | handles salt + oil + wash | coating on brackets, cable jacket |

| Indoor controlled area | powder-coated aluminum or 316L | cost and weight balance | coating quality and touch-up plan |

| High vandal/impact risk | 316L | impact + corrosion together | mount rigidity and hardware torque |

If the material choice is correct, most “corrosion problems” turn into simple maintenance, not emergency replacement.

How do 316L stainless, GRP, and powder-coated aluminum compare for offshore and chemical plants?

Salt air and chemical vapors do not forgive weak materials. A wrong choice looks fine in month one, then turns into rust, seized screws, and leaks.

316L is the safest all-around choice for offshore and many chemical plants. GRP is excellent for severe corrosion and weight limits. Powder-coated aluminum can be cost-effective, but it needs high coating discipline and careful galvanic design.

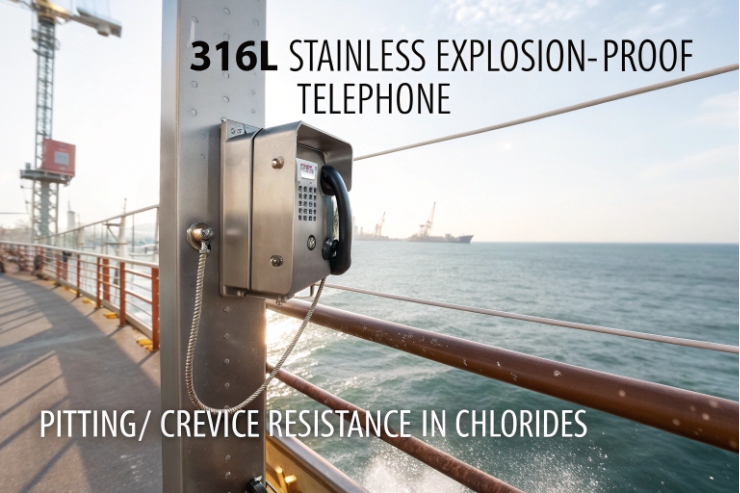

316L stainless steel: the dependable baseline

316L stainless steel 1 is popular for offshore because it resists chloride corrosion better than many steels. It also keeps strength in impacts. In real use, 316L helps in three ways:

-

it does not rely on a coating to survive minor scratches

-

it keeps threads and fasteners more stable over time

-

it stays serviceable after years of weather when matched with correct fasteners

GRP: strong corrosion resistance with different failure modes

Glass Reinforced Polyester (GRP) 2 does not rust. It can be a great choice in chemical plants with aggressive atmospheres. It is also lighter, which helps on structures with weight limits. GRP can also reduce galvanic issues because it is non-metallic.

The risks are different:

-

GRP can age under UV if the formulation is weak

-

impact can cause cracking if the wall design is thin

-

threads and inserts must be designed well to avoid pull-out

Which coatings and finishes—epoxy, polyester, fluoropolymer—deliver longest salt-spray and chemical resistance?

Coatings are often chosen by habit. Then the first scratch or edge chip becomes a corrosion starting point that spreads under the film.

For long life in salt and chemicals, a high-build epoxy primer system is a strong base, polyester topcoats handle UV well, and fluoropolymer finishes offer the best chemical and anti-stick performance when budget and process allow.

Epoxy systems: strong barrier, weaker in UV if not topcoated

Epoxy coatings are known for barrier protection. They resist many corrosive exposures and can achieve strong film build. The implementation of high-quality industrial powder coatings 3 ensures that the phone’s surface remains intact under mechanical stress and chemical splashes.

Polyester powder coat: good UV stability, but watch edges and impact chips

Polyester topcoats handle UV better than many epoxies. That makes them popular for outdoor housings. Still, powder coatings can be vulnerable at sharp edges, corners, and threaded holes. If the coating is thin at edges, corrosion can begin there first.

What standards guide selection—ISO 12944 class, ASTM B117/ISO 9227 hours, and NACE compatibility?

Many specs ask for “corrosion resistant.” That phrase is too weak. It creates debates at FAT and during warranty claims.

A good selection spec uses ISO 12944 corrosivity class for the environment, salt-spray or cyclic corrosion targets like ISO 9227 or ASTM B117 hours as supporting evidence, and NACE-style chemical compatibility to confirm metals, coatings, and elastomers match real plant chemicals.

ISO 12944: write the environment in a recognized way

Using ISO 12944 corrosion protection standards 4 is useful because it describes corrosivity classes and coating system expectations for steel structures and environments. Even when the phone enclosure is not “a steel bridge,” the language helps align everyone on severity.

ASTM B117 and ISO 9227: use salt-spray hours carefully

Salt-spray tests are common evidence. They are easy to compare, but they do not perfectly represent outdoor cyclic reality. Utilizing ASTM B117 salt spray testing 5 as a screening tool helps identify pores and weak edges before the equipment reaches the field.

NACE and chemical compatibility: protect gaskets, fasteners, and glands

Many corrosion failures begin at non-metal parts like gaskets or keypad membranes. Adhering to NACE International corrosion control standards 6 allows engineers to confirm that metals, coatings, and elastomers are compatible with real-world refinery chemicals.

When should marine-grade fasteners, anodized parts, and sacrificial barriers be specified to prevent galvanic corrosion?

Many corrosion problems start at the small parts. A stainless enclosure can still fail if the wrong bolt, washer, or gland creates a galvanic couple.

Specify marine-grade fasteners and galvanic controls whenever dissimilar metals touch in wet, salty, or chemical conditions. Use compatible metal pairs, insulating washers where needed, anodized or coated parts for aluminum, and sacrificial barriers only when the maintenance plan supports inspection and replacement.

When galvanic corrosion becomes a real risk

Galvanic corrosion needs three things: two dissimilar metals, an electrolyte, and an electrical path. Proper galvanic corrosion prevention 7 strategies involve breaking the electrical path with insulating pads or using compatible metal selections to reduce potential differences.

Fasteners: treat them as part of the enclosure system

Marine-grade fasteners are not only a “nice upgrade.” They protect serviceability. Seized screws make maintenance dangerous and slow. For harsh sites, the safe approach is to use 316-grade fasteners with compatible washers.

Conclusion

316L is the safest default for most harsh sites, GRP wins in severe corrosion and weight limits, and coated aluminum needs strict coating and galvanic control to stay reliable.

Footnotes

-

Learn about the chemical composition and corrosion resistance of 316L stainless steel in marine environments. ↩ ↩

-

A guide to the mechanical and chemical properties of Glass Reinforced Polyester used in industrial housings. ↩ ↩

-

Insights into the types and durability of industrial powder coatings for equipment protection. ↩ ↩

-

The international standard for corrosion protection of steel structures by protective paint systems. ↩ ↩

-

Overview of the standard practice for operating salt spray (fog) apparatus for testing material durability. ↩ ↩

-

Access global standards and certification resources from the Association for Materials Protection and Performance. ↩ ↩

-

Understanding the electrochemical process of galvanic corrosion and how to mitigate its effects. ↩ ↩