A phone can be certified for Zone 1 and still fail on a cold morning. Many sites learn this only after the first winter shutdown or the first summer heat wave.

The operating temperature range of an explosion-proof telephone is defined by its certified ambient range (Ta) on the ATEX/IECEx marking, plus practical design limits for cold start, condensation, and long-term seal performance.

Temperature suitability is a certification limit plus a reliability plan?

Operating range is not just a datasheet line

Engineers often see “-40°C to +70°C” and assume the story is done. In reality, temperature performance has two layers:

-

Compliance layer: the certified Ta range and temperature class must remain valid in that ambient.

-

Reliability layer: the phone must still boot, ring, transmit audio, and keep seals intact across daily cycles, humidity, and UV.

A phone can “survive” a low temperature but fail cold start because the keypad is stiff, the LCD is slow, or the PoE supply droops. It can also “survive” high temperature but derate audio power or lose network stability if internal temperature rises.

Why Ta on the marking matters for Zone 1/21

For hazardous area classification 1 zones, Ta is more than comfort. It can be part of the safety case. Temperature class (T-code for gas or max surface temperature for dust) is valid only under stated conditions. If the phone is used outside the certified Ta range, the marking is no longer valid for that installation. That is why the nameplate must be read carefully.

A practical temperature planning checklist

| Temperature topic | What to confirm | Why it matters |

|---|---|---|

| Certified Ta range | on ATEX/IECEx marking | legal suitability for Zone 1/21 |

| Cold start behavior | boot and register at Tmin | real availability in winter |

| Heat performance | call stability and audio at Tmax | reliability in sun and near process heat |

| Humidity/condensation | limits and test evidence | avoids corrosion and keypad failures |

| Storage range | transport and warehouse safety | prevents hidden damage before install |

A short personal placeholder belongs here. One pipeline station project used “-40°C rated” devices, but the cabinet heater failed. The phones stayed alive, but the keypad response was slow and calls were missed. After that, cold start and “ice-cold keypad feel” became a test case, not a marketing claim.

Now the next sections answer your four questions: how Ta appears on ATEX/IECEx markings, cold start and derating realities, what datasheets should state, and how materials and coatings keep reliability across extremes.

Do ATEX/IECEx markings specify -40°C to +70°C ambient (Ta) for Zone 1/21 installations?

Many buyers assume the marking always includes Ta. Some do. Some list only a standard ambient range unless the product is designed for extremes.

Yes. ATEX/IECEx markings can specify a Ta ambient range such as -40°C to +70°C, and for Zone 1/21 installations that Ta range must cover the real site ambient for the marking to remain valid.

What Ta looks like in real marking practice

A typical nameplate or certificate marking may include a line for the ATEX/IECEx certification 2 standard that defines the Ta: -40°C to +70°C range. This is the range where the product is certified to operate while maintaining its stated protection and temperature class (T-code) 3 markings.

Why Zone 21 makes Ta even more important

Dust zones add the risk of dust layers insulating the surface. That means surface temperature can rise above expectation when dust builds up, especially at higher ambient. So for Zone 21:

-

the maximum surface temperature marking must be respected

-

the Ta range must be respected

-

housekeeping assumptions matter

What to do in procurement and inspection

For tenders, the safest wording is:

- “Telephone shall be certified for the stated hazardous area with Ta covering site ambient, minimum -40°C and maximum +70°C if required by project.”

This forces evidence. It also prevents a common mistake: selecting a phone certified only for -20 to +40°C and installing it in a desert or arctic site.

Is cold start guaranteed at -40°C with heaters, and does performance derate above +55°C?

Projects often mix two questions: “is it allowed” and “does it work well.” Cold start and derating live in the second question.

Cold start at -40°C can be achieved when the design supports it and, in some installations, when a certified heater or heated cabinet is used. Performance can derate above +55°C depending on internal heat, sun load, audio amplifier limits, and PoE supply behavior, so a clear derating statement is important.

Cold start at -40°C: what “guarantee” should mean

A real cold start guarantee should include boot time at -40°C and time to SIP registration. In many plants, the phone is fed by Power over Ethernet (PoE) standards 4 from a cabinet switch. PoE availability at low temperature confirms that the switch and power supply also work at that temperature. If the phone is truly exposed at -40°C, the entire chain must be rated.

High temperature: why derating happens

Above +55°C, several things can push internal temperature higher:

-

solar load on metal enclosures

-

heat from PoE converters and audio amplifiers

-

lack of airflow in enclosed modules

-

dust layers acting as insulation

Derating can show up as reduced speaker volume or higher error rates on Ethernet PHY under extreme heat.

What storage vs operating ranges, humidity, and condensation limits should datasheets state?

A phone can arrive damaged before it is installed if storage limits are unclear. It can also fail later from condensation if humidity behavior is not documented.

Datasheets should clearly state operating range (Ta), storage range, humidity limits, condensation expectations, and any required warm-up or environmental constraints, so integrators can design cabinets, heaters, and maintenance plans correctly.

Humidity and condensation: the hidden killers

Many outdoor and tunnel sites have strong humidity swings. High levels of relative humidity (RH) 5 cause condensation to form inside enclosures when temperature changes quickly. Condensation can:

-

corrode PCB pads and connectors

-

degrade speaker and microphone performance

-

reduce insulation resistance and cause faults

-

swell keypads and gaskets over time

A good datasheet states the recommended installation orientation to reduce water traps and inspection requirements for gasket condition.

How do enclosure materials, gaskets, and conformal coating ensure reliability across extreme temperatures?

Temperature swings attack materials before they attack electronics. The phone becomes unreliable when seals leak, plastic hardens, or boards corrode.

Reliability across extreme temperatures comes from stable enclosure materials (316L/GRP/aluminum with correct finish), gasket compounds that retain elasticity at low and high temperatures, and conformal coating and corrosion control inside the device to resist moisture and condensation.

Enclosure materials: manage expansion and weathering

Different materials expand differently with temperature. 316L is stable and strong, but it can transmit cold and heat quickly. GRP insulates better and resists corrosion, but it must be UV-stable and structurally designed for impact. The enclosure design must tolerate thermal cycling without loosening screws or distorting seals.

Conformal coating: helps against condensation and corrosion

The application of conformal coating processes 6 on PCBs can improve resistance to moisture and salt. It is not a replacement for sealing, but it is a useful safety net when condensation happens. A well-coated PCB with controlled connectors and drainage paths can survive humidity swings better.

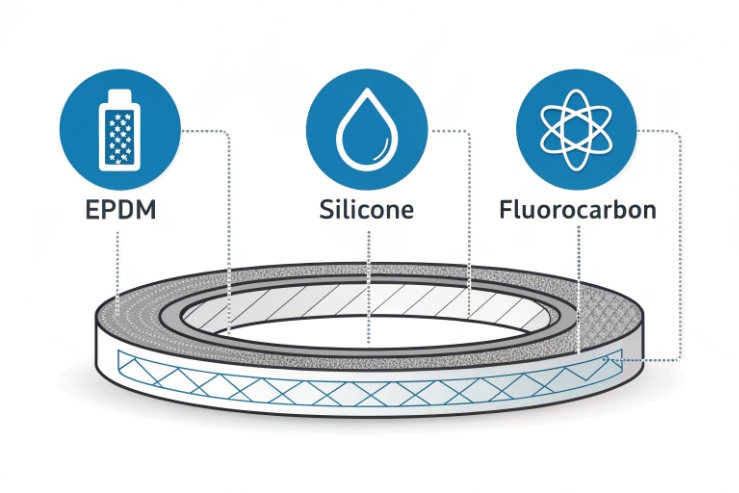

Gaskets: the most important temperature component

Gaskets must keep sealing force at both extremes. A reliable design uses elastomer gasket materials 7 suited for oil exposure, UV exposure, and wide temperature ranges. At low temperature, some elastomers harden and lose compression, while at high temperature, they may take a compression set.

Conclusion

Operating temperature is defined by the certified Ta range plus real cold-start and condensation behavior. A solid design uses suitable materials, wide-range gaskets, and internal protection to stay reliable from deep cold to strong heat.

Footnotes

-

Overview of safety standards and equipment classifications for hazardous area classification in industrial settings. ↩ ↩

-

Official portal for ATEX/IECEx certification, ensuring equipment safety in explosive atmospheres globally. ↩ ↩

-

Technical guide to temperature class (T-code) ratings for identifying ignition hazards in plants. ↩ ↩

-

Detailed explanation of Power over Ethernet (PoE) standards for delivering data and power to devices. ↩ ↩

-

Scientific definition of relative humidity (RH) and its impact on environmental moisture levels. ↩ ↩

-

Introduction to conformal coating processes used to protect electronic circuits from harsh conditions. ↩ ↩

-

Standards and testing methods for elastomer gasket materials to ensure durable environmental sealing. ↩ ↩