Hot air, wet air, and corrosive air can ruin a normal phone fast. In hazardous areas, failure is not only expensive. It can also be unsafe and non-compliant.

Yes, explosion-proof telephones can work in hot and humid environments when the Ex certificate ambient range, IP sealing, and damp-heat test evidence match the real site conditions, and the installation prevents water ingress and condensation.

Heat and humidity are not “just weather” in hazardous sites

What “hot and humid” really does to hardware

Heat and humidity attack equipment in a few simple ways. First, moisture finds paths. It moves through tiny gaps, cable entries, and even through pressure changes when day turns into night. Second, warm moisture turns into condensation when metal cools. Condensation is the silent killer. It can sit on PCB traces, inside microphone cavities, or on terminal blocks. Third, humidity speeds up corrosion. It also makes galvanic corrosion worse when different metals touch. Fourth, humidity can change rubber. Some seals swell. Some harden. Some crack after UV and heat.

Explosion-proof telephones are built to control ignition risk. That usually means a strong enclosure, controlled flamepaths, and certified cable entries. These features help against moisture, but they do not solve every humidity problem by themselves. A phone can be “Ex d” and still fail early if the gasket material is wrong, if the cable gland is badly tightened, or if condensation forms inside the housing.

In our projects for coastal, tropical, and process plants, the best results come from a full match between certification, sealing, materials, and installation details. The phone must be rated for the site temperature range, not only the peak daytime heat. The IP rating must cover washdown, rain, and wind-driven spray. Then damp-heat evidence should show the unit can survive long exposure without corrosion, insulation drop, or sticky keys.

A practical way to think about suitability

A simple method helps: treat the site as three overlapping threats.

1) Moisture entry (rain, hose, spray, fog)

2) Moisture creation (condensation from thermal cycling)

3) Moisture damage (corrosion, leakage current, mold growth, chemical attack)

If a specification only addresses #1 with IP66/67, it may still lose on #2 and #3. That is why damp-heat testing, coating choices, and corrosion-resistant fasteners matter as much as the enclosure rating.

| Threat | What it looks like on site | What to ask for in a spec | What usually fails first |

|—|—|—|—|

| Moisture entry | Driving rain, washdown jets, salt spray | IP66/67 + proven cable gland sealing | Cable entry, gasket compression, speaker grill |

| Moisture creation | Cool nights, AC rooms, shaded walls | Cyclic damp-heat test evidence + condensation plan | PCB, mic capsule, terminal block |

| Moisture damage | Rust stains, green copper salts, sticky keys | Materials list + coating + fastener grade | Screws, springs, contacts, keypad dome |

A short story from the field fits here: a coastal site reported “random audio dropouts” after only two months. The phone body was solid. The real issue was a cable gland without the right insert for the jacket size. Water wicked along the cable braid. After that, the fix was simple: correct gland, drip loop, and a better jacket material.

If these three threats are addressed together, an explosion-proof telephone can run for years in hot, humid places.

This brings us to the proof. Not marketing claims. Proof that stands in front of an EPC contractor and an inspector.

Which ratings prove suitability—relative humidity %, IP66/67, and IEC 60068-2-78/-2-30 damp-heat tests?

Humidity numbers sound clear, but they can hide risk. “95% RH” on a brochure is not the same as a verified qualification. Many buyers need evidence that connects directly to standards.

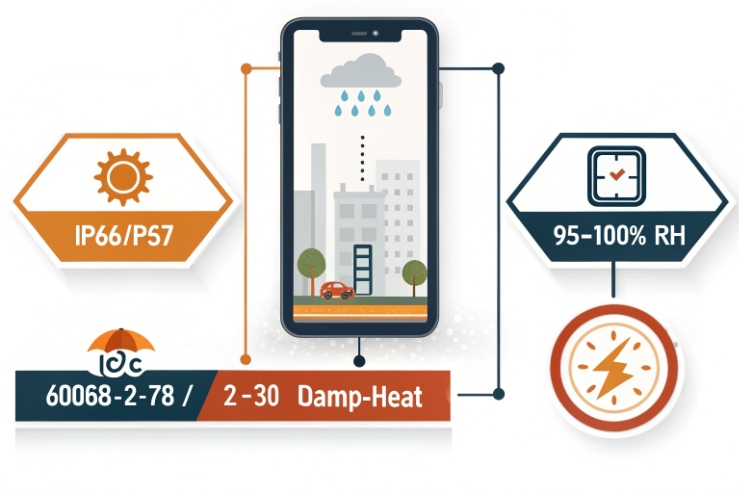

The most useful proof is a combination: Ex certificate ambient temperature range, IP66/67 to IEC 60529 for water entry, and documented damp-heat testing (IEC 60068-2-78 steady-state and IEC 60068-2-30 cyclic) that shows no loss of function or unsafe degradation.

Relative humidity % is a clue, not a qualification

Relative humidity by itself does not define failure risk. A phone can survive 95% RH 1 at 25°C and still fail at 80% RH at 55°C if condensation happens during cycling. The real problem is the dew point and the time of wetness on surfaces. That is why test standards matter. They define a repeatable stress profile, and they make results comparable.

IP66 vs IP67: what they do and what they do not do

IP ratings (IEC 60529 2) are about ingress of dust and water. IP66 focuses on strong water jets. IP67 covers temporary immersion. In hot and humid plants, IP66 often matters more because washdown and driven rain are common. Still, IP ratings do not fully address condensation inside a sealed enclosure. A perfectly sealed unit can still trap moist air during assembly or service. Then temperature swings create water droplets inside.

Why IEC 60068-2-78 and IEC 60068-2-30 help

IEC 60068-2-78 (steady damp heat) stresses materials, insulation resistance, and corrosion behavior under constant high humidity and elevated temperature. IEC 60068-2-30 3 (cyclic damp heat) adds repeated temperature and humidity changes. That cycle is closer to day-night patterns and helps reveal condensation-driven failures. Many procurement specs ask for one or both, but the key is to request test duration, conditions, and pass criteria. “Passed damp heat” is weak unless the report states what was measured.

A solid evidence package usually includes:

-

The Ex certificate showing the allowed ambient range (for example, a range like -40°C to +60°C, if certified) and the temperature class needed for the area.

-

IP test report or certification for the full assembly, including keypad, handset, cable entries, and glands.

-

Damp-heat test report that confirms no cracking, no key sticking, no insulation breakdown, and stable audio performance.

| Evidence item | What it proves | What to verify in the document | Common gap |

|—|—|—|—|

| Ex certificate (ATEX/IECEx or local) | Safe in hazardous atmosphere + allowed ambient | Ambient range, gas group, EPL, T-class | Ambient range missing or too narrow |

| IP66/67 test | Water and dust ingress resistance | Tested configuration matches your order | Different gland or cover used in test |

| IEC 60068-2-78 | Long exposure humidity tolerance | Duration, temperature, RH, inspection results | Only “visual pass” without electrical checks |

| IEC 60068-2-30 | Condensation stress under cycles | Number of cycles, functional checks | No post-test audio or keypad testing |

For buyers, the strongest approach is to treat humidity as a system requirement, not a single rating. Ask for the test reports, not only a statement. Then match the test profile to the site. A tropical coastal platform and a food plant washdown zone are both “humid,” but they fail equipment in different ways.

How is condensation mitigated—breather vents, desiccants, conformal coating (IPC-CC-830), and corrosion-resistant fasteners?

Condensation can appear even when a housing is “sealed.” It forms when the internal air cools below its dew point. That happens during night cooling, rain on a hot enclosure, or when a phone is installed on a cold steel wall.

Condensation is managed by combining pressure control (approved breathers where allowed), moisture buffering (desiccants), surface protection (IPC-CC-830 conformal coating or potting where needed), and corrosion-resistant mechanical design, so droplets do not reach sensitive contacts or create corrosion cells.

Breathers: useful, but only when they do not compromise Ex integrity

A breather vent can reduce pressure pumping. Pressure pumping happens when an enclosure heats up in the sun and cools at night. That cycle can “pull” moist air through tiny gaps. A hydrophobic membrane vent can help equalize pressure without letting liquid water in. In explosion-proof designs, any vent solution must be compatible with the protection concept. Many Ex d housings cannot simply add a vent hole. So the correct method is to use certified components and approved designs, or place venting in a separate certified compartment if the design supports it.

Desiccants: simple and effective when service access exists

Desiccants absorb moisture inside the enclosure. They are low cost and easy, but they need a service plan. In high humidity, a small desiccant pack can saturate faster than people expect. The best use is as a buffer, not as the only strategy. When service is rare, desiccant alone is a risky bet.

Conformal coating: protection for the PCB, not a license to ignore sealing

IPC-CC-830 4 is widely used as a reference for conformal coating performance. A good coating reduces leakage currents, slows corrosion, and improves reliability under condensation. Still, coating must be applied correctly. Masking must keep connectors and test points functional. Thickness must be controlled. Some coatings crack under thermal shock. For very harsh zones, selective potting or fully potted modules can be stronger, but that affects repairability and heat dissipation.

Corrosion-resistant fasteners: small parts, big failures

Fasteners and springs are often the first rust points. Rust expands, breaks coatings, and creates leak paths. The right choice depends on chemicals and temperature. In coastal air, 316 stainless fasteners are common. In chemical plants, a higher alloy or coated fastener may be needed. Also, avoid mixed-metal contact that creates galvanic couples. A strong enclosure can still leak if a corroded screw loses torque.

| Mitigation method | What it reduces | Good fit when | Watch-outs |

|—|—|—|—|

| Membrane breather (certified/approved) | Pressure pumping and moisture draw-in | Outdoor thermal cycling | Must not break Ex protection concept |

| Desiccant pack or cartridge | Internal humidity peaks | Periodic maintenance is possible | Needs replacement schedule |

| IPC-CC-830 conformal coating | Corrosion and leakage on PCB | Condensation risk is real | Process control and masking are critical |

| Potting / sealed modules | Direct droplet impact on electronics | Extreme humidity + vibration | Harder repairs, heat management needed |

| 316/duplex fasteners + anti-seize | Rust and torque loss | Coastal and washdown sites | Wrong paste can attack rubber seals |

The best results come from combining two layers: keep moisture out as much as possible, then protect electronics in case some moisture gets in. In design reviews, the key question is simple: “If a few milliliters of water appear inside, what happens next?” A robust phone stays safe, stays functional, and dries without leaving corrosion behind.

Do gaskets, cable glands, and jackets resist moisture, mold, and chemicals—EPDM/FKM seals, marine-grade metals, and UV-stable plastics?

In hot and humid environments, sealing materials are not just “rubber.” They are chemical parts. A gasket that survives water may fail in oil vapor. A cable jacket that is fine indoors can crack under UV in months.

Yes, they can resist moisture, mold, and chemicals when the sealing system is specified as a full stack: EPDM or FKM chosen for the site chemicals, Ex-rated cable glands matched to cable diameter, marine-grade metals for exposed hardware, and UV-stable plastics or coatings for sun and salt exposure.

EPDM vs FKM: choose based on the chemicals, not on the price

EPDM 5 is often strong for water, steam, and weathering. It also performs well against ozone and UV in many cases. It is a common choice for outdoor moisture sealing. Still, EPDM is not ideal for petroleum oils and some hydrocarbons. FKM 6 (often known by trade names) is strong against many oils, fuels, and solvents. It can also handle heat well, but it may not be the best choice for hot water and steam in some conditions. The safest method is to map the site exposures: cleaning chemicals, oil mist, salt, and temperature.

Cable glands: the most common leak path

Even a perfect enclosure can fail at the cable entry. The gland must be Ex certified for the protection concept and should match the required IP level when installed. The insert must match the cable outer diameter, and the armor clamp (if used) must be correct. In humid sites, water can wick along a cable braid or along strands if there is no proper sealing. Also, a gland should be installed so water does not pool at the entry point.

Jackets and plastics: mold and UV are real

Mold growth is not only cosmetic. It can hold moisture against surfaces and create biofilms that degrade plastics. UV breaks many polymers and can embrittle parts. For outdoor tropical installations, UV-stable plastics (or metal keypads) and UV-rated cable jackets matter. Many sites choose polyurethane (PUR) or chlorinated polyethylene (CPE) jackets for toughness and chemical resistance. If the site has cleaning agents, the jacket must also resist those.

Metals and coatings: “marine-grade” needs details

“Marine-grade” should not be a vague word. 316 stainless is common for coastal use. Aluminum housings can work too if the coating system is strong and edges are protected. Powder coating must be thick enough, and scratches must be avoided during installation. Mixed metals should be controlled to reduce galvanic corrosion.

| Component | Option | Best for | Not ideal for |

|—|—|—|—|

| Gasket | EPDM | Water, outdoor weather, ozone | Oil and fuel exposure |

| Gasket | FKM | Oils, fuels, many solvents, heat | Some hot water/steam exposures, higher cost |

| Cable gland | Ex-rated brass nickel plated / stainless | Mechanical strength and corrosion resistance | Wrong insert size causes leaks |

| Housing | 316 stainless | Coastal humidity, harsh washdown | Higher weight and cost |

| Housing | Coated aluminum | Weight-sensitive installs | Coating damage can start corrosion |

| Plastic parts | UV-stable blends | Outdoor sun exposure | Low-grade plastics become brittle |

In procurement, it helps to request a “materials and sealing schedule.” That is a simple list of gasket material, gland model, fastener grade, and external plastics. It turns “rugged” into a checkable claim. For OEM and ODM projects, our team often starts with the chemical list from the customer. Then we choose seals and coatings that match, and we validate them with damp-heat and corrosion-related checks.

What installation and maintenance practices help—drip loops, weather canopies, correct torqueing, and scheduled gasket replacement?

A rugged phone can still fail if it is installed like a normal indoor device. Water follows gravity. Sun heats metal. People overtighten screws. All of that matters more in hot and humid zones.

The biggest reliability gains come from simple practices: install drip loops and downward cable runs, use canopies in direct rain and sun, torque glands and covers to spec, document inspection intervals, and replace gaskets on a schedule before they harden or take a compression set.

Drip loops and routing: stop water before it reaches the gland

A drip loop is a low point in the cable path that forces water to fall off before it reaches the entry. It is one of the cheapest protections and one of the most ignored. Cable routing should avoid upward-facing gland entries when possible. If the cable must enter from above, a canopy becomes even more important. Also, avoid tight bends that stress the jacket and create micro-cracks.

Weather canopies: sun and rain control in one part

A canopy reduces direct rain impact and reduces solar heating. Less heating means less internal pressure swing, which means less moisture pumping. In very hot climates, shading can reduce enclosure temperature and improve keypad feel. For offshore and coastal sites, a canopy also reduces salt loading, which slows corrosion.

Correct torque: tight enough, not “as tight as possible”

Many leaks come from poor compression control. A gland that is under-torqued leaks. A gland that is over-torqued can cut the seal or deform the insert. Cover bolts also need correct torque so the gasket compresses evenly. A simple torque tool and a written value in the work instruction can remove guesswork.

Scheduled gasket replacement: treat seals like consumables

Gaskets age. Heat speeds up aging. UV can harden exposed edges. Chemical cleaning agents can swell or shrink materials. A planned replacement interval is better than waiting for failure. The interval depends on site severity, but the key is that it is defined, tracked, and tied to inspection records.

A common standard used for hazardous area inspection practice is IEC 60079-17 7. Many plants already follow a similar inspection philosophy. The phone should be included in that program, with checks for corrosion, gland tightness, and gasket condition.

| Practice | What it prevents | Simple check | Typical mistake |

|—|—|—|—|

| Drip loop | Water wicking into gland | Water drips off before entry | Straight cable run into gland |

| Canopy / shade | Overheating and rain impact | Enclosure stays cooler and drier | Mounting in direct sun with no cover |

| Torque to spec | Leaks and seal damage | Torque marks or records | “Hand tight” without tools |

| Periodic inspection | Hidden corrosion and loose glands | Visual + functional call test | Only checking audio, not sealing |

| Gasket replacement plan | Sudden leak after aging | Interval recorded and followed | Reusing old gasket after service |

One more field habit helps: after installation, do a controlled water exposure check that matches the site risk. For example, simulate rain direction, then open the cover later and look for moisture traces. This is not a substitute for IP testing, but it is a practical validation of the real mounting and gland work.

Conclusion

Explosion-proof telephones can thrive in hot, humid sites when ratings, damp-heat evidence, materials, and simple installation discipline work together as one system.

Footnotes

-

Ratio of water vapor present to the maximum amount possible at that temperature. ↩

-

International standard classifying protection against dust and water ingress. ↩

-

Standard for environmental testing, focusing on damp heat and cyclic conditions. ↩

-

Standard for qualification and performance of electrical insulating compounds. ↩

-

Synthetic rubber widely used for its resistance to heat, ozone, and weather. ↩

-

Family of fluoroelastomers offering high chemical and temperature resistance. ↩

-

Standard covering inspection and maintenance of electrical installations in hazardous areas. ↩