A phone can pass IP66 and still fail in public areas. One hard hit can crack a faceplate, bend a door, and destroy the seal.

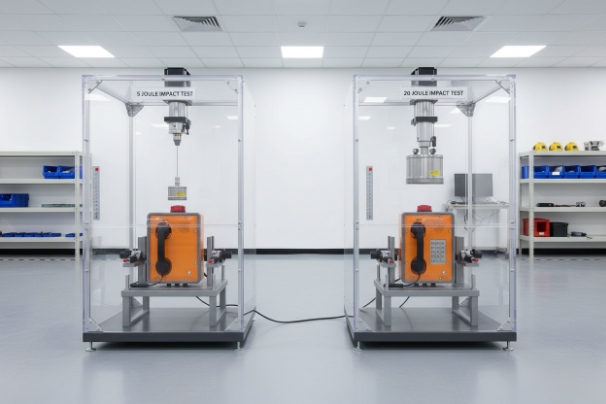

IK08 is built for rough handling and accidental knocks (5 J). IK10 is built for deliberate vandal impacts (20 J). IK10 is about 4× the impact energy, so it needs stronger structure, better mounting, and tighter control of weak parts like windows and keypads.

What changes in the real world when you move from IK08 to IK10?

The jump from IK08 to IK10 looks small on a datasheet, but it feels big on a job site. IK ratings measure impact resistance using standardized impacts. The key practical point is energy. IK08 is 5 joules, and IK10 is 20 joules. That is not “a little stronger.” That is four times the impact energy. When energy rises, failures change type. At IK08, common damage is cosmetic scuffing, small dents, or a cracked plastic corner if someone hits it with a hand tool by accident. At IK10, the risk shifts to structural deformation. Doors bend. Hinges distort. Screw bosses crack. A strong housing can still “survive” the hit but lose gasket compression. Then IP66 is gone.

A second difference is what needs reinforcement. IK08 designs can rely on thickness and basic ribs. IK10 designs often need a full load path. That means the energy must travel from the front face into the mounting plate and into the wall, without crushing the sealing surfaces. For metal housings, that can mean thicker sheet and stronger hinge knuckles. For plastic housings, that can mean a stronger resin, more ribs, and steel inserts where screws take the load.

The third difference is service life. A phone that survives one IK10 hit may still develop micro-cracks, loose screws, or bent brackets after repeated abuse. So an IK10 product should also be designed for repeat hits and for easy field replacement of sacrificial parts like grills and protectors.

Where the 5 J vs 20 J shows up in daily use

- A 5 J hit is closer to a strong accidental tool strike.

- A 20 J hit is closer to a deliberate kick, slam, or heavy blow.

What a buyer should ask for, beyond the IK label

Ask what exactly is certified, how it is mounted during test, and what parts are excluded. Many “IK10 phones” only have an IK10 metal back box, while the window or keypad is lower.

| Topic | IK08 expectation | IK10 expectation |

|---|---|---|

| Damage type | Scuffs, small dents, minor cracks | Deformation, door bending, mounting stress |

| Weak points | Window, keypad edges, handset cradle | Hinge, latch, screw bosses, gasket line |

| Design need | Moderate reinforcement | Full load path to wall + anti-bend structure |

| Risk to IP66 | Medium | High if mounting and door stiffness are weak |

The safe way to buy is to treat IK as a system requirement, not a single number.

A clear understanding of energy, scope, and mounting makes the next decisions easier.

Now the details: energy comparison, certification scope, mounting requirements, and how guards affect audio.

How do impact energies compare—5 J vs 20 J in testing?

A phone can look “tough,” but impact energy sets the real limit. When a customer writes IK10 into a tender, the expectation is a much more violent event than IK08.

IK08 is tested at 5 joules. IK10 is tested at 20 joules. IK10 is four times the energy, so parts must resist bending and not just cracking.

What “joules” means in simple terms

Impact energy is the work delivered by the strike. Higher joules means a harder hit or a heavier striker. If the housing is plastic, higher energy raises the chance of crack initiation at corners and screw bosses. If the housing is metal, higher energy raises the chance of permanent denting and bending. For weatherproof telephones, bending matters because it can open tiny gaps in the door line and change gasket compression.

At 5 J, designs often survive with moderate thickness and reasonable support behind the faceplate. At 20 J, the faceplate needs either higher stiffness or a way to spread the load. A flat faceplate that is only supported at the edges can “oil-can” and transfer stress into screws. This is where many designs fail in the field. The screws stay tight, but the panel yields. Then the door does not close flat.

What a good supplier should document

A good test report states:

- the IK level and energy,

- the impact points used,

- the mounting setup,

- the pass criteria (no access to live parts, no sharp edges, still functional, still sealable).

For weatherproof telephones, a practical pass criterion should include “door still closes correctly” and “gasket line not damaged.” If the test standard does not force that, the project spec should.

Why repeated impacts matter

IK is often tested with a defined number of impacts. Real sites can see repeated hits over months. A design that passes one-time impacts may still fatigue around screw bosses. So it helps to ask if the product is intended for repeated abuse locations, like public corridors, transport stations, and remote outdoor emergency points.

| Impact level | Impact Energy 1 | What usually fails first | What should be reinforced |

|---|---|---|---|

| IK08 | 5 J | Window edge, keypad border, front corners | Faceplate support ribs, window frame |

| IK10 | 20 J | Hinge line, latch, mounting points, door bowing | Hinge structure, latch stiffness, backplate |

If a site has real vandal risk, IK10 is usually the safer spec, but it only works when the whole assembly supports that energy.

Are all faces, windows, and keypads certified to the same IK?

This is where many tenders go wrong. Buyers assume the IK rating covers everything visible. Some suppliers only certify the metal parts, not the full front assembly.

Not always. Some products claim IK10 for the housing shell, while windows, keypads, nameplates, and grills are lower. A serious IK claim should state exactly which parts and which faces are tested at the rated level.

What “all faces” means in practice

A complete IK story should cover:

- front face,

- side faces that can be struck,

- door area and hinge line,

- window or lens,

- keypad area,

- speaker grill.

The front face is the most common strike point. Keypads and windows are also common because they are visible targets. If those parts are not included in the same IK level, the phone may still pass the test but fail in real abuse.

Windows and keypads are the usual weak link

A window can crack from a high-energy strike even if the metal body is fine. A keypad can delaminate or tear at the edges. A grill can deform and touch the speaker membrane. Even if electronics still work, a deformed grill can reduce audio. These failures are not “small.” They drive service calls and can break IP sealing if the deformation changes how parts sit.

What to request in a compliance package

A reliable supplier should provide:

- a test report 2 listing impact points,

- drawings showing which parts were present during testing,

- a statement about window and keypad material and thickness,

- a clear list of exclusions.

If exclusions exist, they should be visible in the datasheet. If the report only says “IK10 housing,” it is worth checking if the “housing” means the back box only.

| Component | Common real-world risk | What to ask the supplier |

|---|---|---|

| Front faceplate | Dent and bow | Was the complete assembly tested? |

| Window/lens | Crack, haze, pop-out | Material, thickness, mounting method |

| Keypad | Tear, edge lift | Sealing method and backing support |

| Speaker grill | Deform, clog | Thickness and support ribs |

| Hinge/latch | Bend, misalignment | Test points at latch and hinge area |

A phone that is “IK10 except for the window” is not truly IK10 in a public abuse zone. The tender should state “front assembly IK10 including window and keypad” if that is the real need.

What mounting and substrate are required to achieve IK10?

Many IK failures happen because mounting is weak. The phone is strong, but the wall flexes, or the backplate bows, so the impact energy concentrates in the wrong place.

To achieve IK10 in real installations, the phone must be mounted to a rigid substrate with the correct anchor pattern and torque. A strong backplate, reinforcement plate, or solid wall (steel or concrete) is often needed, not thin sheet or loose panels.

Mounting must match the test setup

Impact tests are usually done with the product mounted as intended. If the phone was tested on a rigid concrete block with full bolt pattern, and the site mounts it on thin cladding with two screws, the real performance will drop. For IK10, the mounting becomes part of the structure. The wall and anchors must absorb energy without shifting.

What “rigid” means for site work

Good IK10 substrates include:

- reinforced concrete,

- thick steel plates,

- structural columns,

- solid masonry.

Risky substrates include:

- thin metal cabinets,

- hollow panels without reinforcement,

- weak drywall or thin composite boards.

If the site is not rigid, a backing plate 3 solves many problems. A steel or thick aluminum reinforcement plate behind the wall spreads load. It also reduces bolt pull-through.

Fasteners and anchor strategy matter

For IK10, use the full mounting hole pattern. Use tamper-resistant screws 4 if required by the site. Use washers that spread load. Use controlled torque. If screws loosen, the phone starts to rock. Rocking multiplies stress at edges and destroys the seal.

A practical installation pack for integrators should include:

- drilling template,

- anchor type recommendation,

- torque range,

- optional backing plate design,

- notes on cable routing so it does not create a lever arm.

| Installation item | IK10 risk if ignored | Simple best practice |

|---|---|---|

| Substrate rigidity | Wall flex reduces IK level | Use concrete/steel or backing plate |

| Full bolt pattern | Concentrated stress at two points | Use all mounting holes |

| Torque control | Door misalignment and rocking | Set torque and re-check after settling |

| Backing plate | Pull-through or wall damage | Add reinforcement for thin walls |

| Cable strain relief | Cable pulls housing during impact | Clamp cable and avoid stiff bends |

A phone can be engineered for IK10, but it only behaves like IK10 when mounting is treated as part of the design.

Do thicker panels or guards affect audio usability?

A heavier front and stronger guards can protect the unit, but they can also block sound. Many “vandal guards” reduce intelligibility if the acoustic path is not designed carefully.

Yes. Thicker panels, smaller holes, and deep guards can reduce speaker output and change microphone pickup. Good designs use tuned grill patterns, recessed acoustic channels, and membranes so the phone stays loud and clear while staying protected.

How protection hurts audio

Audio needs air movement. A thick plate with small perforations behaves like an acoustic filter. It reduces high frequencies first, then overall volume. A deep recess can create echo and resonance. A guard that sits too close to the speaker can block the sound field. For the microphone, a tight grill can reduce sensitivity and increase wind noise if the airflow becomes turbulent.

These effects get worse when dust and salt clog holes. Coastal sites often create a hard salt crust. Desert sites pack grit into perforations. So a design that “just passes audio” in the lab can become weak in the field.

How to keep audio strong with IK10 protection

The best approach is to separate functions:

- a structural guard to take impact,

- an acoustic layer (membrane and cavity) designed for voice band,

- a serviceable path for cleaning.

Common good practices include:

- larger total open area in the grill, spread across the face,

- short acoustic channels, not deep narrow tunnels,

- water-shedding geometry so salt and rain do not sit in holes,

- acoustic membranes 5 that block water and dust while passing sound.

For loud public areas, it also helps to specify minimum SPL 6 at a defined distance, not only “audio works.” Intelligibility is what matters, not only volume.

Usability trade-offs to check before finalizing guards

Check these points in a sample build:

- voice clarity in wind,

- volume in noisy areas,

- microphone pickup at 30–50 cm,

- cleaning access without removing the whole phone.

| Guard design choice | Impact benefit | Audio risk | Better alternative |

|---|---|---|---|

| Very thick solid plate with tiny holes | High | Low volume, muffled highs | Larger open area with reinforced ribs |

| Deep recessed speaker cavity | Medium | Echo and resonance | Shallow recess with shaped baffle |

| Close-fitting external cage | High | Blocks sound and creates rattle | Stand-off guard with airflow space |

| No membrane, only mesh | Medium | Dust/water ingress risk | Acoustic membrane behind grill |

The best IK10 phones balance impact strength and sound path design. If a project needs both vandal resistance and clear audio, guards should be tested with real voice calls, not only measured on a bench.

Conclusion

IK10 is four times the impact energy of IK08. Real IK10 needs full-front certification, rigid mounting, and guard designs that protect without choking the audio.

Footnotes

-

Explains the correlation between IK code numbers (00 to 10) and impact energy in joules, as defined by IEC 62262. ↩

-

Details the testing procedures and equipment used to certify enclosures for IK impact protection ratings. ↩

-

Describes the function of back panels in enclosures for mounting components and providing rigidity. ↩

-

Overview of tamper-resistant screws and security fasteners designed to prevent unauthorized removal or vandalism. ↩

-

Discusses how acoustic vents protect devices from contaminants while maintaining sound quality. ↩

-

Explains Sound Pressure Level (SPL) measurement and its importance in public address and communication systems. ↩