A wrong conduit thread looks harmless until the gland never seals and the inspector stops the handover. In hazardous areas, that mistake costs days.

Explosion-proof telephones must use the exact cable-entry thread form and size stated on the Ex certificate and drawings. Most projects use Metric M (M20/M25) or NPT (1/2–14, 3/4–14). Correct engagement, sealing, and certified adapters keep IP66/IP67, grounding, and flame paths intact.

The safe rule is simple: match the certified entry, then build the gland system

Explosion-proof telephones sit in places where a bad detail can stop a project. A conduit thread is one of those details. Many people treat the entry thread like a “preference.” That works for normal industrial boxes. It does not work for Ex equipment.

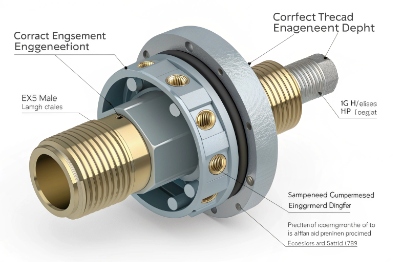

An explosion-proof telephone enclosure 1 is certified with a specific entry design. The thread form, thread tolerance, and the way the gland seals are part of that design. When the entry changes, the risk changes. The risk is not only IP ingress. The risk also includes flame path integrity (for Ex d), dust integrity (for Ex t), and bonding continuity to earth.

In our OEM/ODM projects, the first check is always the same. The team asks for the target market, the protection concept, and the cable type. Then the team locks the entry thread in the drawing set before mass production. This step saves weeks later.

Parallel vs tapered threads decide the sealing method

A parallel thread (most Metric M entries) does not “seal” by thread wedge. The seal usually comes from an O-ring, an IP washer 2, or a gasket face. A tapered thread (NPT) can seal by the wedge effect when it is tightened. Some sites still use sealant or grease for higher IP levels, but the gland instructions must allow it.

Ex compliance is not only about the phone

The entry is a system. The enclosure is one part. The gland is another part. The cable is the third part. Armored cable adds more parts because armor clamping and bonding must be correct. If one part is “almost right,” the full system can still be wrong.

| Decision point | What it controls | What can go wrong if missed |

|---|---|---|

| Thread form (M vs NPT) | Compatibility and sealing method | Cross-thread, poor seal, loss of approval |

| Thread size (M20/M25, 1/2/3/4 NPT) | Cable OD range and space for termination | Gland cannot clamp armor, bending too tight |

| Protection concept (Ex d / Ex e / Ex t) | Flame path vs dust vs safety requirements | Wrong adapter, wrong blanking plug, failed inspection |

| Installation method | Earthing and IP level | Floating shield, corrosion, water ingress |

A conduit thread is a small thing, so people guess. The rest of this article explains how to stop guessing and write a clean, inspection-friendly specification.

If the thread form feels clear now, the next step is to choose the right standard set: NPT, Metric, or other options that some installers still ask for.

Which conduit thread standards should an explosion-proof telephone support?

A contractor may show up with NPT tools and expect NPT. A European site may expect Metric glands by default. If the phone arrives with the wrong thread, the project stops.

Most explosion-proof telephones support Metric ISO “M” threads or NPT threads, because these are widely accepted in hazardous-area gland ecosystems. BSPP (G) and BSPT are not safe assumptions unless the certificate and entry drawing clearly allow them.

NPT is a defined US tapered pipe thread

NPT is a tapered pipe thread used across the US and many global oil and gas projects. It is defined by ASME/ANSI B1.20.1. This matters because installers often think “1/2 inch” is just a size. It is not. The pitch and taper are defined. This is why NPT mates only with the correct counterpart, and why “close enough” becomes cross-thread.

Metric M is the default for many ATEX/IECEx device entries

Metric M entries like M20×1.5 and M25×1.5 are common on Ex enclosures, glands, and adapters. These entries are easy to spec across Europe, the Middle East, and many Asian projects. They also fit well with standard IP sealing washers and O-rings.

BSPP (G) and BSPT exist, but should not be assumed for Ex dust entries

BSPP (G) is a parallel pipe thread. BSPT is a taper pipe thread. Both are widely used in general industry. But hazardous-area rules can be stricter. For dust protection by enclosure (Ex t), an official IEC interpretation 3 for IEC 60079-31 states that only Metric and NPT threaded entries are permitted. The goal is to reduce thread mismatch risk during installation. That statement alone is why a “please offer BSPP too” request needs careful review on dust-zone projects.

A practical way to write the thread standard into a purchase spec

A short spec line beats long emails. This line works well:

- “Cable entry: M20×1.5 (parallel), quantity 1, with certified Ex d/Ex e/Ex t cable gland and certified blanking plug for unused entries, maintain IP66/IP67 after installation.”

| Thread standard | Typical region demand | Seal style in practice | Best use case |

|---|---|---|---|

| Metric M (parallel) | EU, MEA, Asia | O-ring / IP washer | Most ATEX/IECEx projects |

| NPT (tapered) | US, global O&G | Wrench-tight, sometimes approved sealant | NEC-style installs, NPT toolchain sites |

| BSPP / BSPT | Mixed | Varies | Only if certificate and entry design allow it |

The next question is the one that shows up in every project chat group: M20 or M25, 1/2 or 3/4 NPT. The right answer depends on the cable system, not the phone model name.

What thread size should be chosen for cable glands and armored cable?

A phone can be perfect on paper and still fail on site if the gland cannot grip the cable. The installer will force it. Then water enters, or the armor bonding becomes weak.

Choose entry size from the cable system first. M20×1.5 and 1/2"–14 NPT fit many single-cable installs. M25×1.5 and 3/4"–14 NPT give more room for armored cable, larger OD jackets, and easier termination.

Start with cable OD and armor type, not the entry label

Every gland has a cable OD 4 range. Armored glands also have armor range limits. A Cat6 outdoor jacket can be much thicker than indoor Cat6. A braided shield may need different termination than SWA. These details drive the gland model, and the gland model drives the thread size.

Use M20 / 1/2 NPT for compact single-cable installs

A single Ethernet/PoE run with a standard OD often fits well with M20 or 1/2 NPT. These sizes keep the enclosure compact. They also help keep wall thickness strong around the entry. In many Ex telephone housings, M20 is the default because it balances mechanical strength and gland availability.

Use M25 / 3/4 NPT for armored cable, thick jackets, or more installation margin

Armored cable glands are larger. They need space for the armor clamp and the sealing stack. Installers also need space to work with gloves. M25 or 3/4 NPT reduces struggle and reduces “installer creativity.” That matters in hazardous areas.

A simple selection table that works in tenders

| Cable scenario for an Ex telephone | Entry size that usually fits | Why this size is chosen |

|---|---|---|

| Single Cat6 / PoE, non-armored | M20×1.5 or 1/2"–14 NPT | Good gland availability and compact entry |

| Outdoor Cat6 with thick jacket | M25×1.5 or 3/4"–14 NPT | More room for sealing and bend radius |

| SWA / STA armored power or hybrid cable | M25×1.5 or 3/4"–14 NPT | Armor termination needs physical space |

| Two separate cables (Ethernet + I/O) | Two entries, often 2×M20 | Keeps each gland inside its best OD range |

| Retrofit into an NPT-only site | 1/2"–14 NPT or 3/4"–14 NPT | Matches site tooling and conduit ecosystem |

One short story from a chemical plant helps explain this. An integrator chose M20 for a “single cable.” The real cable arrived with armor and a thicker jacket than expected. The gland did not fit. The site asked for an adapter and a new gland. The phone was fine. The schedule was not. This is why the cable spec must be in the same document as the phone spec.

After thread size comes the question that inspectors love: thread engagement and sealing. This part decides if IP66/IP67 is real after installation.

Do ATEX or IECEx enclosures require minimum thread engagement and sealing to maintain IP66/IP67 in hazardous areas?

Water ingress is easy to see. Flame path integrity is not. Dust integrity is also not easy to see. So standards focus on assembly rules that reduce hidden risk.

Yes. Hazardous-area installation rules and Ex enclosure rules set minimum thread engagement for threaded entries, and they also describe how sealing washers, grease, or thread sealants may be used while keeping earthing continuity. IP66/IP67 depends on correct sealing, not only on thread engagement.

Ex d cable entry engagement is a hard requirement

For flameproof concepts, threaded joints matter. Installation guidance based on EN/IEC 60079-14 5 states that flameproof cable glands, adapters, or blanking elements with parallel threads may use a sealing washer, but the thread engagement must still be achieved. It also states that engagement shall be at least five full threads. This is why “one or two turns” is never acceptable on Ex d entries.

Ex d design rules also add another detail. A flameproof enclosure often uses enough thread length so that at least five threads are engaged in the real world, even when chamfers or undercuts exist. This is why you will see requirements like “at least eight full threads” in some enclosure designs. The goal is still at least five fully engaged threads after real tolerances.

Ex t dust entries have their own guardrails

For dust ignition protection by enclosure, IEC 60079-31 includes thread requirements. It also has an official interpretation that restricts threaded entries to metric and NPT. This avoids installers mixing BSP and metric parts by mistake. In dusty sites, a wrong thread match can look “tight” and still leak dust or water.

IP66/IP67 is usually about the face seal, not the thread label

Parallel threads often need a sealing washer or O-ring to reach IP66 and higher. Some manufacturers state that without an entry thread sealing washer on parallel entries, the desired IP level is unlikely to be maintained. Tapered threads can reach IP66 when wrench-tight, but IP67 or IP68 may need an approved grease system and a gland rated for it. The key point is that the gland instructions control what is allowed.

| Protection target | What must be controlled | Common mistake |

|---|---|---|

| Ex d integrity | Minimum thread engagement, no loose joints | Installer adds washer and loses engagement |

| Ex t integrity | Correct thread form, correct tightening | Installer mixes thread systems |

| IP66/IP67 | Correct seal method for the entry | Installer relies on threads only |

| Grounding | Metal-to-metal path, no insulating paint layer | Shield or gland floats, EMI and safety issues rise |

Many installers know how to “make it tight.” Fewer installers know how to prove it stays compliant. That is why certified adapters and reducers are a hot topic in Ex telephone projects.

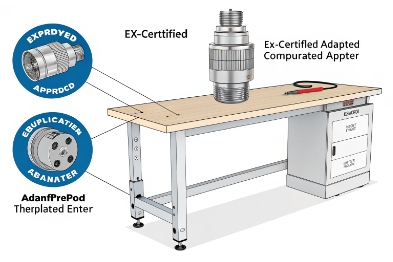

Can thread reducers or adapters be used while preserving flame path integrity, grounding, and certification from vendors and notified bodies?

A site may have existing conduit sizes. A phone may have a different entry. People reach for an adapter and hope for the best. Hope is not a method in hazardous areas.

Certified thread reducers and adapters can be used, but only if they are approved for the same protection concept and installed with the required engagement, sealing, and earthing continuity. Blanking elements should not be installed through adapters, and field thread modifications must follow certification rules.

Use only adapters that are certified for the protection concept

Adapters are not “just metal.” In many systems they are certified components for Ex d, Ex e, and Ex t. Vendors publish dual-certified adapters and reducers that cover metric and NPT options. These parts have markings, temperatures, and gas group limits. Those markings matter for inspection.

Keep the flamepath logic intact

If an adapter adds another threaded interface, it becomes another potential weak point. Standards and vendor guides set rules to reduce that risk:

-

Parallel-thread adapters may use a sealing washer if the minimum engagement remains.

-

Grease may be allowed if it is suitable and earthing continuity stays intact.

-

Unused entries must be sealed using a compliant blanking element fitted directly to the hole. Some guidance states that blanking elements should not be used together with adapters.

Protect grounding and shielding while adapting threads

A common field problem is paint. Paint isolates metal. An adapter may tighten well and still isolate bonding. Bonding matters for safety and for EMC performance. This is why many teams specify a clean bonding surface under the gland or adapter shoulder, and they verify continuity with a simple meter check during commissioning.

Write “adapter permission” into your project spec

This short clause prevents argument later:

- “Thread adapters are allowed only when Ex-certified for the same concept, installed to meet minimum thread engagement, and installed to maintain IP rating and earthing continuity. Adapters shall be supplied with certificates and installation instructions.”

| Adapter topic | What to require | Why it matters |

|---|---|---|

| Certification | ATEX/IECEx certificate and markings | Keeps the safety chain intact |

| Thread engagement | At least five full threads engaged (parallel) | Prevents weak joints |

| Sealing method | IP washer or approved sealant system | Keeps IP66/IP67 real |

| Earthing | Verified metal-to-metal continuity | Prevents floating shields and hot spots |

| Blanking | Blanking plug fitted directly to entry | Avoids extra interfaces |

A reducer can solve a conduit mismatch. It can also create a certification mismatch if it is not controlled. This is why the best project outcome is still to order the phone with the correct entry thread from day one 6.

Conclusion

Pick the entry thread from the Ex certificate, match it to the cable and gland, and use only certified adapters. This keeps flame paths, IP66/IP67, and grounding stable.

Footnotes

-

Robust housing designed to contain internal explosions and prevent ignition of the surrounding atmosphere. [↩] ↩

-

Sealing component used at cable entry points to maintain ingress protection ratings. [↩] ↩

-

Official clarification of IEC standards to ensure consistent application of technical requirements. [↩] ↩

-

The outer diameter of a cable, critical for selecting the correct gland size. [↩] ↩

-

Standard detailing electrical installation design, selection, and erection in explosive atmospheres. [↩] ↩

-

Strategy ensuring component compatibility and compliance from the initial procurement phase. [↩] ↩