Chemical plants do not forgive weak communication. A small device fault can block a critical call during a leak, a shutdown, or a rescue.

Yes. Explosion-proof telephones can be used in chemical plants when the ATEX/IECEx rating matches the zone gas group and temperature class, the housing and seals resist site chemicals, and the SIP system is installed with certified glands, bonding, and clear emergency workflows.

What “fit for a chemical plant” really means?

A chemical plant is not one environment. It is a mix of process areas, pipe racks, pump rooms, tank farms, loading bays, and control buildings. Each area has different gas risks, different corrosion risks, and different network and power risks. That is why the right question is not only “Can it be used?” The right question is “Where will it be used, and what must it survive?”

A practical decision method uses three checks:

Check 1: Hazardous area classification and ignition risk

The phone must match the zone concept used on site. Most chemical plants use Zone 1/Zone 2 for gas areas and Zone 21/Zone 22 for dust when applicable. The Ex marking must match the gas group (IIA/IIB/IIC) and the temperature class 1 (T6–T4). A mismatch is not a small issue. It becomes a project stop.

Check 2: Corrosion and washdown reality

Process areas can include acid vapors, solvent exposure, salt fog near coastal plants, and high-pressure washdown during shutdown. An IP66/IP67 2 label helps, but the seal material and metal parts decide the real life. A seal that swells in oil or cracks in cold will lose IP, even if the enclosure is strong.

Check 3: Integration and operational workflows

A phone is part of a safety system. It must integrate with the SIP platform and also with plant alarms. The plant also needs clear actions when the phone is offline. That can be a beacon, a relay output to PLC, a backup SIP proxy, or an emergency auto-dial rule.

| Plant requirement | What to verify on the phone | What to verify on the system side |

|---|---|---|

| Zone compliance | ATEX 3/IECEx 4 marking fits zone and gas | Site hazardous area dossier and locations |

| Corrosion resistance | Housing finish, seal material, hook metal | Cleaning chemicals and corrosion class |

| Reliable calling | Loud audio, stable SIP | QoS, VLAN, SBC or firewall policy |

| Alarm linkage | Relay I/O, beacon support | PLC/DCS inputs, alarm routing logic |

A chemical plant project goes smoother when these checks are done before purchase. The next sections turn each check into concrete specs and practical field habits.

When the Ex marking is right, everything else becomes easier to approve and easier to maintain.

Which ATEX/IECEx gas group and temperature class fit chemical zones?

A wrong gas group or temperature class can block acceptance, even if the phone “works” in a test room. Safety teams care about marking first.

Choose IIA/IIB/IIC and T6–T4 based on the site’s hazardous area classification and the materials present. When the exact gas risk is uncertain, specify the higher group and lower temperature class to add margin.

Gas groups in plain terms

Gas group is about how easy the atmosphere is to ignite and how a flame can propagate. A simple way to think about it is this:

- IIA covers gases with lower ignition severity in this grouping.

- IIB is stricter than IIA.

- IIC is the strictest of these three and covers the most demanding gas group cases.

Many chemical plants have mixed risks. Hydrogen service, acetylene risk, or some fine chemical processes can push requirements toward IIC. Many petrochemical areas can be IIB or IIA depending on the materials.

Temperature class is about maximum surface temperature

Temperature class ensures the device surface stays below ignition temperature margins. Common classes used in plants:

- T6: max surface temperature around 85°C

- T5: around 100°C

- T4: around 135°C

The safe approach is to match the site’s required temperature class. If the plant uses T6 in a zone, a T4 device is not acceptable, even if it is “cool most of the time.” The marking must match.

Use a simple selection table during early design

A good tender request includes the required group and class for each area. That avoids “one model fits all” mistakes.

| Chemical plant area (example) | Typical hazard focus | Conservative Ex target to request | Why this is often chosen |

|---|---|---|---|

| Pump skid and seal area | Vapors near rotating equipment | IIB or IIC + T6/T5 | Higher risk of leaks and hot surfaces |

| Tank farm and loading bay | Vapors, static, weather exposure | IIA/IIB + T6 | Outdoor plus vapors and washdown |

| Process unit pipe rack | Mixed vapors and heat | IIB + T5/T4 (site-driven) | Heat sources and mixed materials |

| Lab sampling point | Solvents and frequent handling | IIB/IIC + T6 | Human contact and solvents |

A practical margin rule used in projects

When uncertainty exists, the safe direction is:

- Higher gas group (IIC > IIB > IIA)

- Lower temperature class number (T6 is stricter than T4)

This may increase cost, but it reduces rework. In my projects, a single “upgrade” decision early often saves a late redesign after a safety review.

Once the Ex marking is correct, the next fight is usually corrosion and sealing. Many phones pass an IP test when new. The real question is how they survive acids, solvents, and salt fog over years.

Do IP66/IP67 housings and chemical-resistant seals withstand acids, solvents, and salt-fog in process areas?

Washdown and chemicals attack weak points. A phone can have a strong metal body and still fail because one gasket swells or one hook rusts.

IP66/IP67 housings help, but long-term survival depends on the seal material, metal hardware, and cable entry method. A chemical plant handset and door seal should be chosen based on chemical compatibility, UV exposure, and compression-set resistance.

IP rating is only the start

IP66/IP67 tells a story about dust and water ingress under defined tests. It does not guarantee chemical resistance. Solvents can soften plastics. Oils can swell some rubbers. Acid vapors can attack metal finishes. That is why chemical plants should ask for more than “IP67” in a datasheet.

Seal materials: silicone, neoprene, and what matters most

Seal choice should match the site chemistry and temperature range.

- Silicone stays flexible in cold and handles heat well. It can be a strong choice for wide temperature swings and outdoor exposure.

- Neoprene often performs well with many oils and general industrial conditions. It can be a practical choice near oily equipment.

Still, no rubber is “universal.” Solvent exposure can be harsh for many elastomers. The best practice is to request a simple compatibility statement from the vendor based on the site’s cleaning agents and process chemicals.

Metals and hardware: hooks and fasteners decide field life

In coastal plants and salt fog areas, mild steel hooks can corrode quickly. Stainless-steel hooks and fasteners reduce that risk. A corroded hook creates drops, then drops create cracks, then cracks break sealing.

Design details that keep IP stable after years

- A door gasket that keeps compression without taking a permanent set.

- A handset cord entry with proper strain relief and a sealing method that matches the thread type.

- A membrane or acoustic path that keeps water out without blocking voice clarity.

- A housing finish that resists chemical splash and UV.

| Process-area stress | Typical failure seen | Design feature that prevents it | Quick acceptance check |

|---|---|---|---|

| Salt fog and humidity | Rust on hook and screws | Stainless hardware | Visual spec + material statement |

| Solvent cleaning | Swollen gasket, sticky keys | Correct elastomer | Compatibility list for cleaners |

| Acid vapor | Surface attack and staining | Resistant finish | Finish spec + periodic inspection |

| Washdown jets | Water ingress at cord entry | Proper gland and seal | Spray test during commissioning |

A simple habit helps here. Treat seals as consumables in the maintenance plan. The plant already replaces gaskets on valves and pumps. Phones should follow the same logic when installed in the harshest zones.

Once the hardware can survive the environment, the next question is how these phones fit into operations. A chemical plant does not want a standalone phone island. It wants a system that talks to DCS/SCADA and PA/GA.

How do SIP intercoms integrate with DCS/SCADA and PA/GA—SIP, multicast, ONVIF, relays, and alarm beacons?

Integration is where value shows up. A phone that only makes a call is useful. A phone that triggers alarms and supports paging workflows becomes part of safety operations.

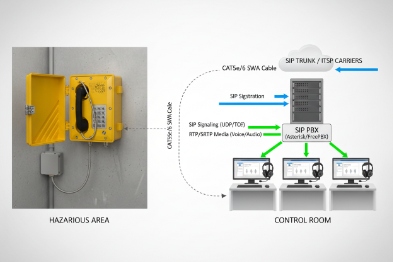

SIP explosion-proof telephones can integrate with plant systems through SIP call routing, multicast paging for PA/GA, ONVIF video linkage when cameras exist, and relay I/O for DCS/SCADA alarms and beacons. Clear routing rules keep emergency calls simple and fast.

SIP integration: keep call routing predictable

Most plants use an IP PBX, a SIP 5 server, or an SBC. The phone registers to the platform and uses simple dial plans:

- Hotline numbers for emergency desks

- Speed dial to control room

- Group ring for area supervisors

- “Red button” logic for immediate calls

A strong emergency workflow uses dedicated extensions and a dedicated queue. It also uses clear caller ID names that include area code and location tags.

Multicast for PA/GA and plant paging

Many plant paging systems use multicast 6 so one talker can reach many endpoints with low delay. A SIP endpoint can join multicast paging groups. This supports:

- Area-wide announcements

- Muster point instructions

- Maintenance broadcast during shutdown

A good practice is to separate paging multicast from control traffic and to use QoS markings so paging does not fight with voice.

ONVIF and video linkage when the site uses cameras

In some plants, a call point is paired with a camera. ONVIF 7 support helps link the call event to video pop-up in the control room. The goal is fast situational awareness. The phone can trigger an event, and the monitoring platform can show the nearest camera view.

Relay I/O and alarm beacons: the OT bridge

Relays and inputs are simple and powerful:

- A relay output can drive a beacon or feed a PLC input.

- An input can accept a door contact, a tamper switch, or a process alarm signal.

This makes the phone part of the alarm chain. It also enables “call on input” workflows, such as auto-dial to the control room when an external alarm contact closes.

| Integration target | Interface | What it enables | One practical tip |

|---|---|---|---|

| DCS/SCADA | Relay I/O or gateway | Alarm status and acknowledgments | Keep logic simple and documented |

| PA/GA | Multicast groups | Area paging and emergency announcements | Use VLAN and QoS separation |

| Video platform | ONVIF + events | Camera pop-up on call | Name devices by location |

| NMS | SNMP/HTTP | Health and fault reporting | Use clear alarm thresholds |

Integration works best when the plant defines a few standard workflows and repeats them across areas. That reduces training and reduces mis-dials during stress.

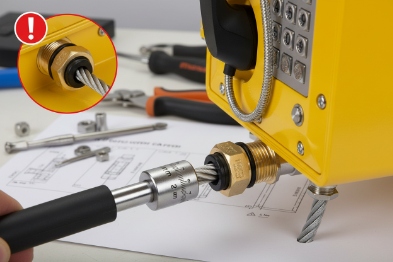

After integration, the final step is safe installation. A phone can be perfectly certified and still become unsafe if the gland is wrong, bonding is weak, or maintenance cannot bypass a failed network path.

What installation practices ensure safety—Ex-certified glands, earthing, armored cabling, maintenance bypass, and emergency auto-dial workflows?

Installation quality decides real safety. A small mistake at the cable entry can break sealing, bonding, or even compliance.

Safe installation uses Ex-certified glands matched to the enclosure thread, solid earthing and bonding, correct armored cable termination, coordinated surge protection, and tested workflows like maintenance bypass and emergency auto-dial that do not create nuisance calls.

Ex-certified glands and correct thread engagement

Cable glands 8 must match:

- The phone entry thread (M20/M25 or NPT)

- The cable type (unarmored, braided, SWA/STA)

- The protection concept required for the zone

Armored cable needs correct armor bonding. If the armor is not terminated correctly, earthing can be weak and EMI can rise.

Earthing and bonding: keep impedance low

Hazardous areas use equipotential bonding 9 to reduce spark risk and to keep surge currents controlled. A phone enclosure should bond to the local earth network. The bond point must be clean metal-to-metal, not through paint. A short, robust bonding method helps more than a long thin wire.

Surge protection and ground loops in long runs

Outdoor cable runs and pipe racks can pick up surge energy. SPDs should be coordinated:

- Primary protection at building entry

- Secondary protection closer to the endpoint when runs are long

The grounding path for the SPD must be short and direct. A long ground lead reduces SPD performance. A poor SPD install can create more problems than it solves.

Maintenance bypass and continuity planning

Plants need a plan for “PBX down” or “uplink down.” A few workable patterns:

- Secondary SIP proxy on a different network path

- Local call routing within the same site even if WAN fails

- A backup call route to a local control room extension

- A clear manual bypass procedure during network maintenance

Emergency auto-dial workflows with guardrails

Auto-dial is useful when the phone has a dedicated emergency button or input trigger. Still, it should be controlled so it does not create false calls:

- Use a long press or a guarded button for emergency

- Add a cooldown timer after an auto-dial event

- Disable auto-dial during planned maintenance windows

- Log every auto-dial trigger with time and reason

| Installation item | What to do | What it prevents | Quick field check |

|---|---|---|---|

| Ex gland selection | Match thread and cable type | Seal failure and compliance issues | Verify markings and thread fit |

| Armor termination | Bond armor correctly | EMI and weak earth path | Continuity test to earth bar |

| Earthing | Short, clean bond point | Sparks and noise | Visual + resistance check |

| SPD coordination | Stage protection and ground short | Port damage and outages | Inspect SPD and grounding lead |

| Maintenance bypass | Define fallback call route | Loss of comms during outages | Test with uplink disabled |

| Auto-dial guardrails | Press rules and cooldown | Nuisance calls | Simulated trigger test |

In chemical plants, the safest practice is to treat the phone like any other safety endpoint. It needs a correct installation method, a documented test, and a periodic inspection plan.

Conclusion

Explosion-proof telephones are suitable for chemical plants when Ex rating, chemical resistance, system integration, and certified installation practices are planned together and verified during commissioning.

Footnotes

-

temperature class A classification system (T1 to T6) that limits the maximum surface temperature of equipment to prevent ignition of flammable gases. ↩

-

IP66/IP67 Ingress Protection ratings defining resistance to powerful water jets (66) and temporary immersion (67). ↩

-

ATEX EU directives regulating equipment and protective systems intended for use in potentially explosive atmospheres. ↩

-

IECEx International certification system for equipment used in explosive atmospheres, facilitating global trade. ↩

-

SIP Session Initiation Protocol; a signaling protocol used for initiating, maintaining, modifying and terminating real-time sessions. ↩

-

multicast A method of network communication where a single stream of data is sent to multiple recipients simultaneously. ↩

-

ONVIF An open industry forum for the development of a global standard for the interface of physical IP-based security products. ↩

-

Cable glands Mechanical cable entry devices designed to attach and secure the end of an electrical cable to the equipment. ↩

-

equipotential bonding The practice of electrically connecting all exposed metal parts to minimize voltage differences and prevent shock or sparks. ↩