Coal mines punish weak communication. One bad call point can slow rescue, delay evacuation, and turn a small fault into a bigger incident.

Yes. Explosion-proof telephones can be used in coal mines when the approval matches underground mining rules, the enclosure survives coal dust and humidity, the network design stays redundant, and installation follows Ex glands, barriers, bonding, and tested emergency workflows.

A coal-mine decision framework that avoids wrong approvals and early failures

Using an Ex telephone underground is not the same as using it in a refinery. Coal mines are “Group I” in the ATEX/IECEx world, and many regions also require mining-specific approvals. If the phone shows a normal “Zone 1 IIC” label, it can still be rejected for underground coal because the approval scope is different.

A solid decision framework starts with four questions.

1) Is the approval scope correct for underground coal?

Underground coal often needs Group I and a protection level that matches the mine’s operating rules. Some sites demand equipment that remains safe and functional even when methane or coal dust is present. Other sites allow equipment to shut down when gas rises. That is the difference between M1 and M2 logic in many tender documents.

2) Is the product a “system” match, not only a device match?

A mine phone depends on the network, the power, and the cable entry. The approval can be invalidated by the wrong cable type, wrong gland, wrong barrier, or poor standby power design. In some regions, even the cable routing and flame-resistant conduit are part of the compliance story.

3) Is the housing built for coal dust, vibration, and wet air?

Coal dust behaves like fine abrasive powder. It gets into seams. It holds moisture. It contaminates keys. That is why IP and IK ratings 1 matter, but the real winners are good seals, hard hardware, and serviceable handset and cord parts.

4) Can the phone prove health and trigger the right action?

Underground operations need fast proof. The phone should expose link state, SIP state, and power state. The system should also support staged failover and local alarms.

| Decision item | What “good” looks like | What usually fails projects |

|---|---|---|

| Approval fit | Group I mining approval or regional mine approval | Using “Zone 1 IIC” approvals only |

| Dust and water defense | IP66-level sealing plus gasket plan | Good IP label, weak long-term gaskets |

| Shock and handling | IK10-style impact resistance | Cracked handset shells and loose hooks |

| Network uptime | Redundant uplinks and redundant SIP | One switch per area, no backup |

| Emergency workflow | Simple auto-dial and alarm outputs | Complex dial plans and no test route |

A buyer can treat this framework like a filter. If one item fails, it is cheaper to fix it on paper than in a tunnel. The next sections cover the same questions in tender-ready detail.

If approval is solved first, the rest of the engineering becomes calmer.

Which approvals fit underground coal—ATEX/IECEx Group I M1/M2, Ex d/Ex i, or regional MA/MSHA?

Underground coal procurement fails fast when approvals are unclear. A supplier may say “ATEX certified,” but the mine inspector asks for a mining group mark.

Underground coal usually needs Group I mining approvals with an M1 or M2 protection level, plus a protection concept like Ex d (flameproof) or Ex i (intrinsically safe). Many regions add local mining marks such as China MA/KA or U.S. MSHA approval for mine communication devices.

Group I M1 vs M2: how to choose

M1 and M2 are not “better vs worse.” They match operating philosophy.

- M1 aligns with equipment that should stay safe and keep working even when an explosive atmosphere is present. This fits refuge stations, escape routes, and critical call points.

- M2 aligns with equipment that can be switched off or de-energized when an explosive atmosphere is present. This fits non-critical areas where shutdown is acceptable.

In a tender, the safest method is to list each underground location and state whether the call point must remain functional during a gas event. That single sentence often decides M1 vs M2.

Ex d vs Ex i: what fits a mine telephone

Two concepts show up most in mine discussions:

- Ex d 2 (flameproof enclosure) is common for rugged telephones because it allows normal power levels and strong audio. It relies on a certified enclosure and controlled cable entries.

- Ex i 3 (intrinsically safe) is common when the circuit must remain safe by limiting energy. It often uses barriers or isolators. It can be harder to pair with higher-power features like loud ringers, beacons, or full PoE budgets.

A practical approach is to use Ex d for most fixed stations and use Ex i where the mine safety philosophy demands energy limitation at the circuit level. This is not a universal rule. It is a project pattern that reduces surprises.

Regional approvals: plan them early

Coal mines are regulated differently by region.

- In the U.S., MSHA 4 has an approval and certification program for certain products used in underground coal and gassy mines. Communication and signaling devices can fall under those rules.

- In China, MA/KA marks 5 are common tender requirements for equipment used in coal mines.

The clean tender move is to ask for a compliance matrix. The matrix should list: ATEX/IECEx mining group marking, plus any regional mining approvals needed by the project country.

| Approval need | What to request from the vendor | Why it reduces risk |

|---|---|---|

| Group I mining marking | Certificate and marking photo | Proves the scope is underground mining |

| Protection concept | Ex d or Ex i statement plus conditions | Avoids wrong power and wiring plans |

| Regional mine approval | MSHA or MA/KA evidence if needed | Prevents late rejection on site |

| Cable and accessory scope | Approved glands and cable rules | Stops “approval breaks during install” |

A coal mine is not the place to “sort out approvals later.” The best time is before the cable is pulled.

Once approvals are correct, the next failure mode is physical: coal dust, vibration, humidity, and rough handling.

Do IP66/IK10 housings and stainless hardware resist coal dust, vibration, and high humidity underground?

Coal dust gets everywhere. Humidity stays high. Vibration never fully stops. A phone that looks strong can still fail in months if the weak point is the cord, gasket, or hook.

Yes, IP66-level sealing and IK10-level impact resistance are strong targets for underground fixed telephones. Still, real survivability comes from gasket choices, corrosion-resistant hardware, vibration-tolerant mounting, and serviceable handset and keypad parts.

Coal dust behavior and what it breaks first

Coal dust is not only “dust.” It is abrasive. It also holds moisture and becomes conductive when mixed with grime. It attacks:

- Keypads and hookswitch mechanics

- Handset cords and strain relief boots

- Gasket surfaces at doors and cable entries

- Speaker and microphone ports

That is why the best designs avoid deep crevices and use sealed acoustic paths that do not trap dust. A dust-loaded handset port can cut intelligibility even when the electronics are fine.

Stainless hardware and anti-corrosion choices

Stainless hooks and fasteners are worth the cost underground. Mines see constant wet air and cleaning. Rusted fasteners lead to loose covers. Loose covers lead to gasket failure. A small fastener choice becomes an uptime choice.

If the housing is stainless or coated metal, the coating system must handle scratches. Underground maintenance tools will scratch surfaces. A coating that fails after one scratch is not a real mine coating.

Vibration and mounting: keep the seal stable

Many phone failures blamed on “water ingress” start as vibration loosening.

- Use locking hardware on mounting brackets.

- Use strain relief that does not pull on the gland.

- Avoid cable routes that tug on the handset cord.

A simple practice is to add a scheduled torque check in high-vibration zones. This is cheap and prevents slow seal failures.

Fast tests that catch wear before failure

A mine phone should be tested like safety gear:

- Monthly “echo test call” to confirm mic and receiver

- Keypad digit test to confirm no bounce or stuck keys

- Visual check of gasket compression and cable entry tightness

- Check that the hook-switch state changes cleanly

| Underground stress | What it causes | Design feature that helps | Quick site test |

|---|---|---|---|

| Coal dust + grime | Key bounce, muffled audio | Sealed keypad, protected ports | DTMF 6 test + echo test |

| High humidity | Corrosion, leakage paths | Stainless hardware, coating plan | Visual check and log review |

| Vibration | Loose covers, seal drift | Lock washers, stable brackets | Torque check schedule |

| Rough handling | Cracks and drops | IK10-level build, strong hook | Drop marks and hook inspection |

Durability is the “silent spec” underground. When it is done well, nobody notices. When it is done poorly, the phone becomes a weekly ticket.

Once the phone can survive, the next problem is system integration. Mines use mixed networks like fiber rings and leaky-feeder systems, and the phone must fit that reality.

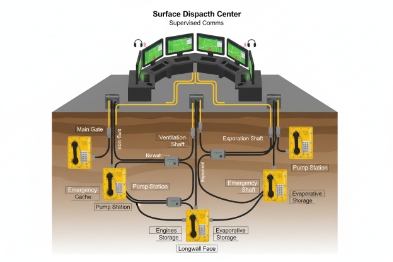

How do these telephones integrate with SIP PBX, PA/GA, leaky-feeder, fiber rings, and redundant PoE power?

Underground voice is never one network. Mines mix fixed IP, radio, paging, and alarm systems. A phone must connect to the tools that crews already trust.

SIP mine telephones integrate with a SIP PBX for calling, with PA/GA using multicast paging or gateways, and with leaky-feeder systems through dispatch and radio gateways. Fiber rings and redundant PoE switches keep voice alive when one path fails.

SIP PBX integration: simple and repeatable call flows

A fixed mine phone should have:

- Hotline to control room

- Speed dial to rescue and ventilation control

- Group ring for shift supervisors

- Clear location labels in caller ID

The dial plan must be short. Crews use gloves and work under stress. Short is safer.

PA/GA and paging: multicast where it fits

Many mines use paging for evacuation and coordination. A SIP phone can support paging in two main ways:

- Join a multicast paging 7 group for one-to-many announcements

- Call into a PA/GA gateway that drives amplifiers and speakers

Multicast is efficient but must be planned with VLAN and QoS. Paging should not fight with camera traffic or SCADA bursts on the same uplink.

Leaky-feeder: connect the worlds, do not confuse them

Leaky-feeder 8 is mainly a radio distribution method. It supports handheld radios across long underground routes. A SIP telephone is usually a fixed Ethernet endpoint. The integration point is often a dispatch gateway:

- SIP calls can be patched to radio talk groups through a gateway

- Radio emergency events can trigger a SIP call or a control-room screen event

This approach keeps the SIP phone strong at fixed points while radio handles mobility.

Fiber rings and redundant PoE: build for partial failure

Underground networks fail in segments. A cable gets damaged. A switch loses power. A ring design reduces outage spread.

A stable design includes:

- Fiber ring or redundant uplinks between underground nodes

- UPS-backed PoE switches 9 in key zones

- Two SIP proxies or a primary/secondary registration plan

- Clear QoS policy so RTP stays ahead of bulk traffic

| Integration target | Method | What it enables | One project rule that helps |

|---|---|---|---|

| Fixed calling | SIP 10 PBX | Direct voice to control room | Use consistent extension naming |

| Paging | Multicast or PA gateway | Area announcements | Separate paging VLAN or QoS class |

| Radio mobility | Leaky-feeder + gateway | SIP-to-radio patch | Keep gateway in a protected room |

| Network resilience | Fiber ring | Path redundancy | Test ring failover during commissioning |

| Power resilience | Redundant PoE + UPS | Keeps phones alive during outages | Monitor PoE load and alarms |

Integration is not only “can it connect.” It is “can it keep working when one part breaks.”

That leads to the final topic: safe installation. Coal mines are strict about cable entries, flame resistance, barriers, and emergency workflows.

What installation practices ensure safety—Ex-certified glands, intrinsically safe barriers, earthing, armored cabling, and emergency auto-dial workflows?

Most underground failures start at the cable entry or the power path. A perfect phone becomes unreliable when glands, bonding, and barriers are treated like optional accessories.

Safe mine installation uses certified glands that match the enclosure thread, correct IS barriers where Ex i circuits exist, strong earthing and bonding, armored or protected cabling, and a tested emergency workflow that includes auto-dial rules and maintenance bypass.

Ex-certified glands and cable entry discipline

Cable glands must match:

- Entry thread type and size on the phone

- Cable outer diameter and armor type

- Mine requirements for flame resistance and mechanical protection

A gland is not only a seal. It is strain relief, bonding, and a compliance item. Wrong glands create water ingress and also create certification risk.

Intrinsic safety barriers: only where the circuit is Ex i

If the design includes Ex i circuits, barriers or galvanic isolators belong in the safe area or in a certified enclosure. The wiring must follow the barrier parameters. Mixing IS and non-IS wiring in the same tray without segregation can break the safety concept.

A simple rule works well: treat Ex i wiring like instrumentation loops. Label it. Route it cleanly. Keep it separate.

Earthing, bonding, and ground loop control

Mines can have noisy power environments. Good bonding helps both safety and communication stability.

- Bond the enclosure with a clean metal-to-metal contact

- Avoid paint under bonding points

- Keep bonding conductors short and robust

- Coordinate earthing between network cabinets and local structures

Ground loops are a real risk when long runs connect different ground references. A controlled bonding plan reduces random noise and reduces PHY port damage.

Armored cabling and mechanical protection

Underground cable damage is normal. The design should assume it.

- Use armored cable or protected conduit where mechanical damage is likely

- Add bend radius control near glands

- Use cable clamps so the gland does not carry the cable weight

Emergency auto-dial workflows with guardrails

Auto-dial can save time. It can also create nuisance calls if it triggers during maintenance.

A safe workflow includes:

- Long-press emergency button or guarded button

- Cooldown timer after an auto-dial event

- A maintenance disable mode

- A local audible or visual indicator that shows the call is active

- Logging for every auto-dial event and every failure event

| Installation item | What to do | What it prevents | Commissioning check |

|---|---|---|---|

| Glands and entries | Use certified glands, correct torque | Seal failure and loose strain relief | Visual + pull test |

| IS barriers | Install and wire to barrier limits | Energy faults in Ex i circuits | Verify labels and wiring routes |

| Bonding | Short, clean bonding points | Spark risk and EMI issues | Continuity check |

| Cable protection | Armor or conduit where needed | Cuts and crushing | Route walkdown |

| Auto-dial | Guardrails and test route | Nuisance calls and confusion | Simulated trigger test |

A final field habit makes a big difference: keep a small spare kit in a safe store near the shaft. A handset module, a keypad module, a gasket set, and one spare gland set can cut downtime from days to hours.

Conclusion

Explosion-proof telephones fit coal mines when mining approvals, dust-proof durability, redundant networks, and strict installation practices are planned together and proven by on-site tests.

Footnotes

-

IP and IK ratings Standards defining levels of protection against ingress (dust/water) and mechanical impact, crucial for rugged environments. ↩

-

Ex d Flameproof enclosure protection method where the housing contains any internal explosion and prevents transmission to the outside atmosphere. ↩

-

Ex i Intrinsic safety protection method that limits electrical energy to levels insufficient to ignite an explosive atmosphere. ↩

-

MSHA Mine Safety and Health Administration; the U.S. agency regulating mine safety and equipment approval. ↩

-

MA/KA marks Mandatory safety certification marks for mining products used in Chinese coal mines. ↩

-

DTMF Dual-Tone Multi-Frequency signaling; the system used for telephone signaling over the line in the voice-frequency band. ↩

-

multicast paging A network efficiency method where a single audio stream is sent to a group of IP devices simultaneously. ↩

-

Leaky-feeder A communication system used in underground mining and tunnels, using a cable that leaks radio signals to provide coverage. ↩

-

PoE switches Network switches that deliver power and data over the same Ethernet cable to connected devices. ↩

-

SIP Session Initiation Protocol; a signaling protocol used for initiating, maintaining, and terminating real-time sessions. ↩