Many projects buy the wrong protection concept. The phone passes paperwork, but installation becomes slow, maintenance becomes risky, and the site ends up with dead endpoints.

Ex d (flameproof) explosion-proof telephones should be used when the area is Zone 1 or Zone 2 and the site wants a rugged device that can contain an internal ignition, especially for tougher gas groups like IIC (hydrogen) and where intrinsic safety is not practical. The Ex marking must still match gas group, temperature class, EPL, and ambient range.

Ex d selection logic that works on real sites

Ex d is often treated as the “default” explosion-proof method. That is not always wrong, but it should be chosen for clear reasons. Ex d 1 means the enclosure is designed to withstand an internal explosion and cool the flame so it cannot ignite the outside atmosphere. That design drives everything: wall thickness, flamepaths, threaded joints, cover bolts, and the way cable entries are sealed.

The real decision is a four-step match

1) Zone / EPL: Zone 1 usually needs EPL Gb. Zone 2 usually needs Gc. Many Ex d products are marked Gb and can be used in Zone 1 and Zone 2 (because Zone 2 allows the same or higher protection level).

2) Gas group: IIA, IIB, or IIC. If the area can contain hydrogen, acetylene, or similar, IIC is often required.

3) Temperature class: T1 to T6. The phone must not exceed the required surface temperature in the worst ambient.

4) Ta range and conditions: If the unit is only certified for -20 to +40°C, a tank farm in extreme climates can fail compliance on day one.

A compact mapping table for engineers and buyers

| What the site needs | What to select on the nameplate | Why Ex d fits |

|---|---|---|

| Zone 1 phone on process unit | Ex d / Ex db, EPL Gb | Strong mechanical protection and clear compliance path |

| Hydrogen possible | IIC | Flamepaths are tested for the hardest gas group |

| Hot climate or sunload | Correct T-class 2 at required Ta | Stops surface temperature non-compliance |

| Outdoor washdown and storms | IP66 3 or higher | Ex d protects ignition, IP protects water/dust ingress |

Ex d is not the only valid choice. Ex e and Ex i can be better in some cases. The right answer comes from what the site values most: ruggedness, simple field service, energy limits, or cabling simplicity.

The next sections break this down in the same way a refinery or terminal project team actually makes the call.

Which hazardous zones and gas groups require Ex d—Zone 1/2, IIC hydrogen, and T-rating limits?

Confusion starts when “explosion-proof” is used as one label for many protection concepts. Zone and gas group do not “require Ex d” by themselves. They require a protection concept that is certified for that zone and gas group.

Ex d telephones are commonly used in Zone 1 and Zone 2, and they can be certified for IIA/IIB/IIC gas groups including IIC hydrogen. The device must also meet the site-required temperature class (T1–T6) and the certified ambient (Ta) range, because T-class compliance can change with ambient temperature.

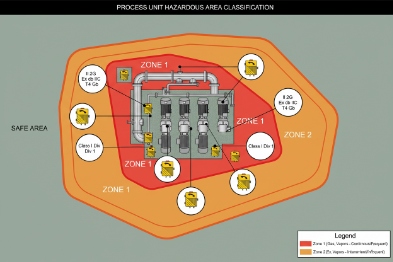

Zone and EPL: the practical requirements

For gas hazards:

- Zone 1: explosive gas atmosphere is likely in normal operation. Equipment should be EPL Gb (or higher).

- Zone 2: explosive gas atmosphere is not likely in normal operation, and if it occurs it is short. Equipment should be EPL Gc (or higher).

Most Ex d telephones for industrial use are marked Gb, so they fit Zone 1 and can also be placed in Zone 2.

Gas group: what “IIC hydrogen” means for the phone

If the hazardous area file lists hydrogen, acetylene, or similar high-risk gases, the equipment must be suitable for IIC. A phone marked IIC can also be used in IIB and IIA areas (within the same zone/EPL). The reverse is not acceptable.

Temperature class: the common trap in hot outdoor areas

Temperature class limits the maximum surface temperature. The required T-class is set by the area classification and the substances present. The phone must meet that T-class at the actual ambient.

A safe habit for terminals and loading racks is to check:

- the marking for T rating, and

- the certificate for Ta range, and

- any special conditions if the certificate has an “X” suffix.

A selection table that avoids under-spec

| Requirement from area classification | Minimum Ex d telephone marking intent | Notes |

|---|---|---|

| Zone 1 | Ex db … Gb | Gb fits Zone 1; confirm gas group and T-class |

| Zone 2 | Ex db … Gc or Gb | Gb is acceptable; many sites standardize on Gb |

| Hydrogen possible | … IIC … | Do not accept IIB or IIA in hydrogen zones |

| Low surface temperature required | … T6 or T5 as specified | Confirm T-class at worst Ta, not only at +40°C |

In practice, Ex d is used because it can be certified up to IIC and it tolerates industrial abuse. Still, it is not always the best approach for every telephone location.

When is Ex d preferred over Ex e or Ex i in refineries, tank farms, and loading racks?

The wrong concept increases cost in hidden ways. Ex d can be heavier and slower to service. Ex i can require barriers and careful loop calculations. Ex e can restrict what components are inside.

Ex d is preferred when the site wants a robust, self-contained device for Zone 1/2, when cable runs and power needs make intrinsic safety difficult, and when mechanical durability and straightforward compliance matter more than ultra-low energy circuits. Ex i is preferred when maintenance safety and live work are priorities, while Ex e is used when the design can avoid arcs and hot surfaces with enhanced insulation and terminals.

What each concept “feels like” on a project

- Ex d (flameproof): strong enclosure, contains internal explosion. Good for harsh areas and higher-power electronics. Heavier. Requires careful handling of joints and entries.

- Ex e 4 (increased safety): prevents arcs and hot surfaces by design and insulation. Often used for junction boxes, terminals, and simple devices. Not ideal if the device has components that can spark in normal operation unless combined with other concepts.

- Ex i 5 (intrinsic safety): limits energy so ignition cannot occur. Great for live maintenance and small-signal circuits. Needs barriers/isolators and strict installation control.

Where Ex d wins in refineries and terminals

Ex d is often the best fit when:

- The phone is in Zone 1 near process equipment, valves, pumps, or loading arms.

- The device needs PoE power or higher internal energy than typical intrinsic safety circuits allow.

- The phone is exposed to impact, vibration, and abuse, and the owner wants a metal enclosure that stays compliant after years.

- The site wants to reduce system complexity. Ex d endpoints often feel simpler than Ex i loops with barriers and documentation.

Where Ex i wins for telephones

Ex i is attractive when:

- The site demands safer maintenance practices, including work without opening flameproof joints.

- The phone is part of a low-energy signaling system, or the design supports certified Ex i Ethernet/PoE methods in the project standard.

- The owner wants lighter devices and easy field replacement with minimal hot work concern.

Where Ex e appears in telephone projects

Ex e is less common as a standalone approach for a full telephone, because phones have speakers, hook switches, and electronics that may not fit Ex e alone. Still, Ex e often appears in connection compartments or as part of a combined marking (for example, Ex db eb) where terminals are Ex e and the main enclosure is Ex d.

A quick decision table used in tender reviews

| Location | Common project preference | Reason |

|---|---|---|

| Loading rack call point (Zone 1, outdoor) | Ex d | Rugged, tolerates exposure and abuse |

| Tank farm gate or perimeter (often Zone 2) | Ex d or industrial non-Ex outside zone | Simple standardization; depends on exact boundary |

| Analyzer shelter or control room edge | Ex i or Ex e (if allowed) | Easier maintenance and wiring control |

| Offshore modules with strong corrosion/impact | Ex d with 316L 6 | Mechanical and environmental robustness |

A good spec does not “ban” Ex d or “push” Ex i by habit. It matches the site’s maintenance culture, power/network design, and lifetime cost.

What enclosure materials and IP ratings suit corrosive, salt-fog, and washdown—316L, powder-coated aluminum, and IP66/IP67?

Marine air, coastal terminals, and chemical cleaning can destroy the wrong enclosure fast. Then the phone becomes a maintenance burden.

For corrosive and salt-fog environments, 316L stainless steel with 316 fasteners is the safest default. Powder-coated aluminum can work when the coating system is proven and maintained, but it is more sensitive to scratches and edge damage. For washdown and outdoor storms, IP66 is typically the baseline, and IP67 is a strong choice where temporary flooding or heavy splash exposure is credible.

316L stainless: the simplest “long life” story

316L is widely used because it resists many chloride exposures better than basic stainless. It also handles cleaning chemicals better than many coatings. Still, the full assembly must match:

- 316L housing

- 316 fasteners

- compatible glands

- isolation from dissimilar metals

Powder-coated aluminum: workable, but must be treated as a coating system

Aluminum housings are lighter and can be cost-effective. The risk is not the base metal alone. The risk is coating damage:

- scratches at cable entry

- chips on edges

- bolts cutting into paint

- UV aging of the coating

If the coating fails, corrosion can creep under it. On terminals, that can become a recurring repair cycle.

IP rating for harsh sites: focus on the installation point

- IP66 fits heavy rain and hose washdown. It is the most common “industrial outdoor” target.

- IP67 adds temporary immersion tolerance. It fits low points, pits, and areas with storm flooding history.

Material + IP pairing table

| Environment | Best material direction | Practical IP target | Extra detail that saves maintenance |

|---|---|---|---|

| Coastal terminal and ports | 316L | IP66 (IP67 if flood risk) | Stainless glands and fasteners, anti-galling practice |

| Chemical plant washdown | 316L or proven coating | IP66 | Seal material compatible with cleaners |

| Inland refinery outdoor | 316L or coated aluminum | IP66 | UV-stable seals and proper gland torque |

| Offshore splash zone | 316L (or duplex) | IP66/IP67 | Salt-fog screening and strict entry sealing |

If the phone is mission-critical, 316L + IP66 is usually the lowest-risk baseline. The cost difference is often paid back by fewer service calls.

How do wiring and maintenance differ for Ex d—cable glands, conduit seals, hot work permits, and inspection schedules?

Most lifecycle cost of Ex d devices is not the initial purchase. It is the time spent installing and maintaining them correctly.

Ex d wiring and maintenance require certified flameproof cable glands or conduit sealing methods, controlled handling of flamepaths and threaded joints, and disciplined inspection. Opening an Ex d enclosure is usually treated as higher-risk work, often tied to hot work or gas-free requirements depending on site rules. Inspection schedules focus on flamepath condition, gland tightness, and enclosure integrity.

Wiring differences: entries are part of the protection concept

For Ex d, the cable entry is not a casual accessory. It is part of the certified safety boundary.

Key practices:

- Use Ex d certified cable glands that match the cable type and diameter range.

- For armoured cables, use the correct gland design for armor termination and earth bonding.

- Use certified blanking plugs for unused entries.

- Follow thread engagement rules and sealing washer rules as defined by the product and gland documentation.

In some conduit systems, projects require conduit seals (sealing fittings) to prevent gas migration through conduit. This is common in North American practices and in sites that follow similar methods. The exact requirement depends on local code and the project standard.

Maintenance differences: flamepaths must stay perfect

Ex d enclosures use flamepaths 7 such as threaded covers or machined joints. These surfaces must not be scratched, corroded, or modified. Maintenance must treat them like precision parts.

Common maintenance rules:

- Clean flamepaths gently. Do not use aggressive tools.

- Inspect for corrosion, nicks, or deformation.

- Replace gaskets with correct parts, and do not “upgrade” gasket material without approval.

- Torque bolts correctly and in the correct sequence.

- Confirm gland tightness and cable sheath condition.

Permits and work control: why Ex d feels “heavier” on site

Many sites require that Ex d enclosures are opened only when:

- the area is made safe (gas-free), or

- the work is controlled under permit systems.

Some teams refer to this as “hot work style control,” even when the actual permit type varies by site. The idea is consistent: opening a flameproof enclosure in a hazardous atmosphere is not treated as routine.

Ex i systems are often easier for live maintenance because the circuit energy is limited by design. Ex d systems rely on enclosure integrity, so the enclosure must not be opened casually in a live hazardous atmosphere.

Inspection schedule focus points for Ex d telephones

| Inspection item | What to check | What failure looks like |

|---|---|---|

| Flamepaths / threads | No damage, correct engagement, no corrosion | Cover binds, visible pitting, damaged threads |

| Cable glands | Tightness, correct seal, no sheath damage | Moisture ingress, loose cable, cracked seal |

| Blanking plugs | Correct certified plug installed | Open hole, wrong plug type |

| Fasteners | Correct grade, no seizure, correct torque | Missing bolts, rust, stripped threads |

| IP integrity | Gaskets and membranes intact | Water ingress, audio distortion, corrosion inside |

A field habit that reduces downtime

Keep a small service kit: approved gaskets, blanking plugs, and a torque guide. Many failures come from improvisation during a night shift. A controlled kit prevents “almost fits” repairs that break the rating.

Ex d is a strong solution when the site wants ruggedness and certified containment. The tradeoff is that wiring and maintenance must follow stricter discipline. That discipline is manageable when the project specifies glands, permits, and inspection steps from day one.

Conclusion

Use Ex d telephones for Zone 1/2 when rugged, self-contained protection is needed, including IIC cases, and manage the lifecycle with correct glands, flamepath care, and disciplined inspection.

Footnotes

-

Ex d Flameproof enclosure protection method; contains an internal explosion without allowing it to ignite the external atmosphere. ↩

-

T-class Temperature Class; a rating system (T1 to T6) that limits the maximum surface temperature of equipment to prevent ignition of specific gases. ↩

-

IP66 Ingress Protection rating indicating the enclosure is dust-tight and protected against powerful water jets. ↩

-

Ex e Increased Safety protection method; prevents arcs, sparks, or excessive heat in normal operation and specified fault conditions. ↩

-

Ex i Intrinsic Safety protection method; limits the electrical energy in equipment and wiring to levels insufficient to ignite an explosive atmosphere. ↩

-

316L A low-carbon version of 316 stainless steel, offering superior corrosion resistance, particularly in marine and chloride environments. ↩

-

flamepaths The joint surfaces of a flameproof enclosure (like threads or flanges) designed to cool escaping gases and prevent external ignition. ↩