Dust hazards can turn a normal phone into a fire starter. A wrong selection can also fail inspection and stop a plant handover.

Yes, explosion-proof telephones can be suitable for dust hazardous zones when the marking matches Zone 21/22 (EPL Db/Dc), the dust group (IIIA/IIIB/IIIC), and the enclosure sealing and surface temperature limits required by the site.

Dust suitability is more than “Ex” on the label

Dust risk behaves differently than gas risk

Gas hazards spread and clear quickly. Dust hazards build up slowly. Dust also sits on equipment and creates insulation. That insulation can raise surface temperature. Dust can also enter small gaps and damage switches, terminals, and keypads. Because of this, dust compliance is not only about ignition control. It is also about ingress protection, long-term sealing, and cleaning discipline.

The selection must follow the site hazard dossier

A dust-zone selection starts with the site classification data 1:

-

Zone 21 or Zone 22

-

Dust group (IIIA fibers, IIIB non-conductive dust, IIIC conductive dust)

-

Dust ignition characteristics (cloud and layer)

-

Maximum ambient temperature where the phone will be installed

-

Cleaning and dust layer expectations in that area

We treat these as “must match” inputs. Then the phone marking and manual must show that the product was designed and tested for those conditions.

The common failure points we see in real deployments

Most dust-zone failures are not fancy. They are basic:

-

A phone is marked for gas only, but installed in a dust zone.

-

The enclosure is fine, but the gland is not dust-tight for the cable OD.

-

The stopping plug is not certified or not installed correctly.

-

Housekeeping is weak, dust layers grow, and surface temperature margins shrink.

-

Maintenance opens the enclosure incorrectly and dust enters the terminal area.

| Item that must stay correct | What usually goes wrong | What we do to prevent it |

|---|---|---|

| Dust marking (Db/Dc + group) | Buying “Ex” without dust marking | Copy marking into the tender text |

| Sealing level | Wrong gland insert or wrong torque | Lock gland model by cable OD |

| Surface temperature | Ignoring dust layers and sun heating | Specify dust surface temp margin + Ta |

| Inspection readiness | Missing certificates and manuals | Ship a complete compliance pack |

A dust-zone phone becomes reliable when it is selected, installed, and maintained as a sealed safety device.

Which ATEX/IECEx dust zones apply—Zone 21/22 with EPL Db/Dc and groups IIIA/IIIB/IIIC?

Dust zones can look simple on a drawing, but the wrong group choice can block approvals and create safety gaps.

Zone 21 usually requires EPL Db, Zone 22 usually requires EPL Dc, and the dust group (IIIA/IIIB/IIIC) must match the site, with IIIC used when conductive dust is possible.

How Zone 21 and Zone 22 are used in industry

Zone 21 is a place where a combustible dust 2 atmosphere is likely during normal operation. Zone 22 is where it is not likely during normal operation, or it is short-lived. Many plants have Zone 22 around handling areas, with Zone 21 close to filling points, transfer chutes, or bagging machines.

For explosion-proof telephones, the practical meaning is:

-

Zone 21 needs a higher equipment protection level than Zone 22.

-

Zone 21 devices often need stricter enclosure sealing and stricter surface temperature control.

Dust groups decide what the enclosure must resist

Dust groups are often written as:

-

IIIA: combustible flyings and fibers

-

IIIB: non-conductive dust

-

IIIC: conductive dust 3

Conductive dust is a serious risk because it can bridge terminals and create faults. When a site cannot guarantee “no conductive dust,” it is safer to specify IIIC.

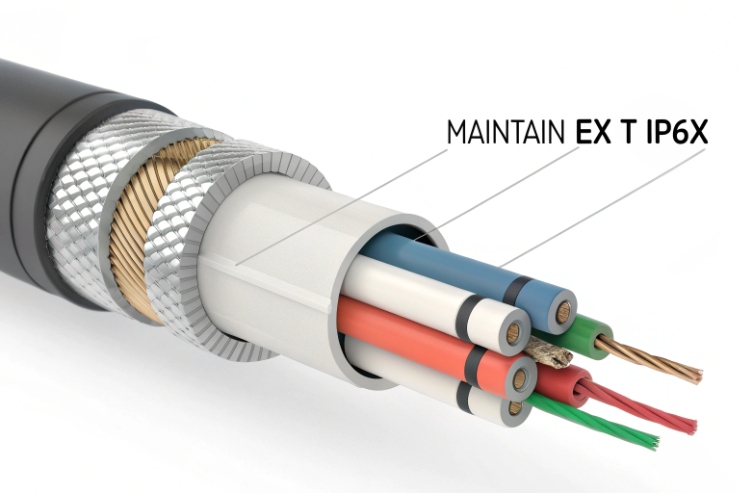

What IP and temperature limits are required—IP6X sealing and surface T-class for combustible dust layers?

Dust does not need a big opening. It needs a small gap and time. That is why sealing is a top requirement in dust zones.

Dust-zone phones normally need dust-tight enclosure protection as a safe baseline, and the marking must state a maximum surface temperature for dust that stays below the site dust ignition limits within the stated Ta ambient range.

IP sealing: why “IP6X” matters

In dust environments, the goal is to stop dust entry into the enclosure and terminal areas. The IP sealing 4 level is a common target because it reduces long-term drift in performance. Many sites also request IP66 or IP67 for wash-down, rain, and condensation.

Surface temperature for dust is not the same as gas T-code

For gas, the marking uses T4/T5/T6. For dust, the marking commonly states a Maximum surface temperature 5 in °C. Dust layers can insulate surfaces. That is why dust temperature limits must consider dust cloud ignition risk, dust layer ignition risk, and expected dust layer thickness.

| Dust-zone constraint | What to specify | What it protects |

|---|---|---|

| Dust ingress control | Dust-tight sealing target + correct glands | Prevents internal contamination |

| Dust surface temperature | Marked max surface temp (°C) | Prevents smoldering and ignition |

| Ambient range (Ta) | Ta min/max covers real weather | Keeps marking valid outdoors |

| Cleaning reality | Housekeeping level and inspection plan | Prevents insulation build-up |

Do enclosures and glands maintain dust protection—Ex t/Ex d/Ex e markings, certified cable glands, and stopping plugs?

Most dust-zone nonconformities come from the cable entry. The enclosure may be certified, but the installed entry hardware can break compliance.

Yes, dust protection can be maintained when the enclosure marking supports dust (often Ex t for dust by enclosure), and when certified glands and stopping plugs match the entry threads, cable type, and required sealing performance for Zone 21/22.

Cable glands must match three things at once

A correct selection of cable glands 6 must match the protection concept, thread type, and cable outer diameter. Armored cable adds another rule: the gland must terminate armor correctly while keeping sealing performance. Stopping plugs also matter; an unused entry must be sealed with a certified plug that matches the same protection concept and thread.

How do dust zones map to North American Class II, Div 1/2, and what documents are needed for tenders?

Global projects often fail on paperwork, not hardware. Dust-zone compliance must be provable in the local regulatory language.

Dust Zone 21 is closest in intent to Class II Division 1, and Dust Zone 22 is closest to Class II Division 2, but the mapping is not a legal conversion, so tenders should require the correct certificates and marking for each region.

A safe way to write the mapping in tenders

We avoid claiming a direct equivalence table. A safer tender approach is to require the North American classification 7 (UL/CSA) approval for Class II Div 1/2 when the project is in that region. This keeps the project compliant with the authority having jurisdiction and avoids arguments during inspection.

| Tender deliverable | Why the reviewer needs it | What it prevents |

|---|---|---|

| IECEx CoC / ATEX certificate | Confirms dust approval scope | Wrong device installed in dust zone |

| Marking plate photo | Quick match to dossier | “Looks Ex” selection mistakes |

| Ta + surface temp marking | Validity in site conditions | Hidden temperature noncompliance |

| Accessory certificates | Gland/plug compliance | Dust ingress and audit failures |

Conclusion

Explosion-proof telephones can serve dust zones when dust EPL, group, sealing, surface temperature, and certified glands match the site dossier, and the tender package proves compliance for inspection.

Footnotes

-

A guide to the NFPA 70 National Electrical Code for hazardous area classifications and equipment standards. ↩ ↩

-

Learn about OSHA’s safety regulations and standards for managing combustible dust hazards in workplaces. ↩ ↩

-

Technical definition of conductive dust and its impact on electrical equipment safety in industrial environments. ↩ ↩

-

Detailed explanation of the Ingress Protection code system for measuring resistance against dust and water. ↩ ↩

-

Official guide to Equipment Protection Levels and surface temperature limits for hazardous area certifications. ↩ ↩

-

Overview of cable glands and their critical role in maintaining device integrity and environmental sealing. ↩ ↩

-

Comprehensive overview of North American standards for electrical safety in classified hazardous locations. ↩ ↩