A Zone 1 area is not forgiving. If the phone marking is wrong, the site can reject the installation even if the device powers up and makes calls.

Yes, explosion-proof telephones can be used in Zone 1 when the ATEX/IECEx marking shows Category 2G or EPL Gb with the correct protection concept (Ex d and/or Ex e), gas group (IIB or IIC as required), and a temperature class that matches the hazard and ambient range.

Zone 1 suitability is proven by the nameplate and the installation method?

Zone 1 1 is a “normal operation” risk level

Zone 1 means a flammable gas atmosphere is likely to occur in normal operation. That is why the phone must have a higher protection level than Zone 2 devices. Many industrial phones look similar on the outside, but only the marking and certificate decide whether Zone 1 use is allowed.

A safe approach uses two checks:

1) Product check: the certificate and marking must match Zone 1 expectations.

2) Installation check: the glands, threads, bonding, and maintenance rules must match the protection concept.

If either check fails, the installation becomes non-compliant.

Typical Zone 1 use cases for telephones

Zone 1 phones are common in:

-

refinery process units 2 near pumps and valves

-

loading bays and chemical transfer areas

-

offshore module edges and certain decks

-

compressor and turbine enclosures (depending on classification)

These places also bring harsh conditions. Salt, wash-down, vibration, and UV often exist at the same time. This is why “Zone 1 rating” is not enough. Environmental fitness must be verified too.

The quick selection logic

A Zone 1 phone should typically show:

-

ATEX II 2G (gas) marking or IECEx EPL Gb

-

protection concept like Ex d/Ex db and/or Ex e/Ex eb

-

gas group IIB or IIC based on site requirement

-

temperature class T4/T5/T6 suitable for the process hazard

-

ambient range Ta that covers real weather, such as -40°C to +70°C when required

| What you want | What to look for | Why it matters |

|---|---|---|

| Zone 1 gas suitability | II 2G or Gb | confirms protection level |

| Robust enclosure concept | Ex d/db, often with Ex e/eb terminals | controls ignition risk and wiring method |

| Worst-case gas group | IIC if required | avoids group mismatch |

| Safe surface temperature | correct T-code | prevents ignition by hot surface |

| Outdoor readiness | Ta, IP66/67, corrosion stack | prevents downtime after commissioning |

With this foundation, the rest is execution: the right glands, correct thread engagement, and correct maintenance discipline. That is what keeps the marking valid over life.

Now let’s answer your four points in a clean way.

Which ATEX/IECEx marking 3 confirm Zone 1 suitability—Ex d or Ex e, EPL Gb, gas group IIB/IIC, and required T-code?

Marking is the decision tool. If the marking does not match, the answer is “no,” even if the product label says “explosion-proof.”

Zone 1 suitability is confirmed when the marking shows Category 2G (ATEX) or EPL Gb (IECEx), with a protection concept such as Ex d/db and/or Ex e/eb, and a gas group (IIB or IIC) and T-code that match the site classification.

How to read the key Zone 1 parts

A nameplate may show a marking string similar to:

- II 2G Ex db IIC T6 Gb

This is an example format, and exact letters vary by certificate.

Break it down:

-

II: surface industries

-

2G: category for gas, commonly used for Zone 1 suitability

-

Ex db: flameproof enclosure method (Ex d family)

-

IIC: gas group severity

-

T6: surface temperature class for gas

-

Gb: EPL level suitable for Zone 1 risk level

Some phones show Ex eb for the terminal chamber. That usually means the terminal area is designed for increased safety. A combined marking is common and can be a good sign, because it supports safer terminations.

What gas group to specify

If the site classification says IIC, require IIC. If the site is IIB, an IIC phone still works and may simplify spares, but it can increase cost. The safest tender wording is to match the dossier, then allow “higher group accepted” if procurement wants flexibility.

How to handle T-code properly

T-code selection must match the hazard ignition temperature and the worst-case ambient. T6 is more stringent than T4. Still, the T-code is only valid within the stated Ta range. If the phone is used outside Ta, the temperature marking may not hold.

| Site requirement | Acceptable marking indicator | Safe procurement wording |

|---|---|---|

| Zone 1 gas | II 2G or Gb | “Certified for Zone 1 (Category 2G / EPL Gb)” |

| Severe gas group | IIC | “Gas group IIC (or higher if stated)” |

| Hot surface limit | T4/T5/T6 | “T-class shall meet site hazard” |

| Terminal safety | Ex e/eb chamber | “Ex e terminal compartment preferred” |

Once the marking is confirmed, environmental fitness must be checked. Zone 1 often sits outdoors or near wash-down zones. That is where IP, impact, and temperature range become real selection requirements.

Do IP66/67 4, IK10 5, and -40–+70°C ratings meet Zone 1 environmental demands?

Zone rating answers “can it be installed there.” Environmental rating answers “will it stay working there.”

Yes. IP66/67, IK10, and -40 to +70°C are strong environmental targets for Zone 1 locations like process units and offshore modules, but they must be validated together with the Ex certificate Ta range, corrosion resistance, and correct glands that preserve IP.

IP66/67 and what they protect against in Zone 1

IP66 protects against dust ingress and strong water jets. IP67 adds short-term immersion protection. In Zone 1 plants, the biggest threats are:

-

hose-down wash

-

wind-driven rain

-

dust and fine particles

-

condensation in tunnels and covered modules

An IP rating becomes real only when the installation preserves it. The main failure point is the cable gland. The gland must match cable OD and sealing method. If not, the phone may pass a bench test and fail in the field.

IK10 for rough handling and maintenance

Zone 1 areas are busy. Tools hit housings. Handsets get dropped. An IK10 class device is more likely to survive routine abuse without cracking seals or deforming the enclosure.

-40 to +70°C: good target, but check Ta on the Ex marking

Many projects require -40°C because of outdoor winters and remote stations. Many require +70°C because a metal enclosure in sun can run hot. The key is to confirm:

-

the Ex marking includes a Ta range that covers your requirement

-

the phone still meets its T-class inside that Ta range

-

the keypad, handset cord, and labels are rated for those temperatures

| Environmental demand | What to check | What usually fails first |

|---|---|---|

| Wash-down | IP66/67 + gland sealing | gland leak and gasket compression set |

| Outdoor exposure | UV and corrosion stack | labels fade, screws seize, coat edge creep |

| Impacts | IK rating + mount strength | loose bracket, cracked front plate |

| Temperature extremes | Ta range + elastomer behavior | keypad hardening and cord stiffness |

Environmental ratings do not replace Ex requirements. They sit beside them. When both are satisfied, the phone becomes stable in real Zone 1 service.

Next, installation rules decide whether the phone keeps its Zone 1 compliance over life. This is where accessories, bonding, and flamepath care matter most.

What installation rules apply—approved Ex cable glands, thread types, bonding/earthing, and flamepath maintenance?

Most site nonconformities come from installation details, not from the phone itself.

Zone 1 installation must follow the phone’s certificate and manual: use approved Ex cable glands and stopping plugs matched to Ex d/e concepts, use correct thread types and engagement, bond/earth the enclosure as required, and maintain flamepaths, fasteners, and gaskets without modification.

Cable glands: match the protection concept 6 and cable type

A phone may have Ex d main housing and Ex e terminal chamber. That means the entry method can be different by chamber. The safe rule is:

-

Use only glands listed as acceptable for the phone’s entry type and protection concept.

-

Match gland sealing range to the cable outer diameter.

-

Use correct washers, seals, and torque and do not improvise.

Stopping plugs must also be approved and correctly torqued. An unused entry is not “free.” It must be sealed with the right plug.

Thread types: do not mix metric and NPT by force

Thread mismatch is a common field mistake. It damages the entry and can void compliance. For Zone 1, thread integrity also affects sealing and mechanical strength. A correct project locks the entry thread type at design stage:

-

M20/M25 metric, or

-

NPT, depending on the product variant

Adapters should be avoided unless they are certified and accepted for the protection concept. When adapters are used, the project should document them.

Bonding/earthing: protect safety and EMC

Bonding is not only about safety. It also controls noise and stability for SIP and PoE. A good practice is:

-

bond the enclosure to the local equipotential bonding network

-

follow a consistent shield termination plan

-

avoid floating shields in high EMI zones

Flamepath and enclosure maintenance rules

For Ex d equipment, flamepaths and cover interfaces must be protected:

-

do not machine or sand flamepaths

-

keep them clean and free of corrosion

-

use the correct fasteners

-

keep torque and closing procedure per the manual

-

do not open in hazardous area while energized unless procedures allow

| Installation item | What to do | What it prevents |

|---|---|---|

| Glands | Ex-certified and matched to entry | invalid Ex and IP failure |

| Stopping plugs | certified and torqued | moisture ingress and nonconformity |

| Threads | correct type and engagement | damaged entries and leaks |

| Bonding | equipotential bonding | touch voltage and EMC noise |

| Flamepath care | clean, undamaged, correct bolts | loss of Ex d integrity |

Now the last question: how Zone 1 maps to North American Divisions and what tender documents should be included. This is important for global EPC projects, offshore assets, and US or Canadian owners.

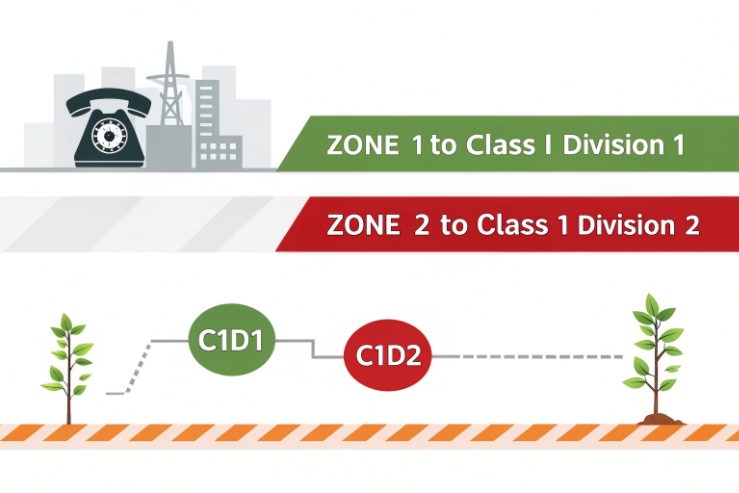

How does Zone 1 map to North American C1D1/C1D2, and what documentation must be provided for tenders?

Many tenders need both IEC-style and North American-style language. The mapping is similar in intent, but it is not a perfect conversion.

Zone 1 is closest in risk intent to Class I Division 1 7, while Zone 2 aligns more closely to Class I Division 2, but the final acceptance depends on the site classification method and AHJ. For tenders, provide certificates, marking details, and installation conditions clearly for each required system.

Practical mapping language that avoids overpromising

A safe way to write this in a tender is:

-

“Device shall be certified for IECEx/ATEX Zone 1 (EPL Gb / Category 2G) as specified.”

-

“Where North American classification applies, device shall be certified for Class I Division 1 with the required gas group.”

This avoids claiming a direct equivalence table. It also allows the project to select the correct variant per region.

Tender documentation checklist that speeds approvals

A strong tender package for Zone 1 includes:

-

Certificate copies or certificate numbers for IECEx and/or ATEX (and UL/CSA when required)

-

Nameplate marking photo and marking string

-

Stated Ta range and temperature class

-

Installation manual with approved entry methods and gland requirements

-

QA evidence where required by the certification route (such as manufacturing quality assessment references)

-

A list of approved accessories: glands, plugs, reducers, materials

| Tender deliverable | Why it is needed | Who uses it |

|---|---|---|

| IECEx CoC / ATEX certificate | proves compliance | HSE and inspection team |

| Marking photo | avoids mismatch disputes | commissioning team |

| Installation manual | correct gland and torque | installer and QA |

| Accessory list | prevents wrong gland use | procurement and warehouse |

| Ta and T-class data | ensures outdoor validity | engineering team |

When these documents are complete, Zone 1 acceptance becomes routine. When they are missing, projects lose time in the last mile.

Conclusion

Explosion-proof telephones can be used in Zone 1 when the marking shows Category 2G or EPL Gb with correct Ex concept, gas group, and T-class, and when glands, threads, bonding, and flamepath maintenance follow the certificate and manual.

Footnotes

-

Comprehensive overview of electrical equipment safety standards in hazardous industrial environments. ↩ ↩

-

Insights into the energy efficiency and safety infrastructure of modern oil and gas refineries. ↩ ↩

-

Official IECEx portal for international certification of equipment for use in explosive atmospheres. ↩ ↩

-

Detailed explanation of the Ingress Protection (IP) code system for measuring resistance to dust and water. ↩ ↩

-

Standards for the protection provided by enclosures for electrical equipment against external mechanical impacts. ↩ ↩

-

Technical guidelines for various methods used to protect electrical equipment in hazardous locations. ↩ ↩

-

Occupational safety regulations and definitions for hazardous locations according to North American standards. ↩ ↩