Refinery noise, corrosive mist, and strict zoning can turn a simple wall phone into a compliance headache and a safety gap.

Yes, explosion-proof SIP telephones are widely used in refineries when the certification matches Zone or Class/Division requirements, the enclosure resists corrosion and washdown, and the network plus power design supports reliable emergency calling.

The refinery requirement stack: compliance, durability, and uptime

Refinery phone projects succeed when the spec is written as a stack, not as a single line like “Ex phone, Zone 1.” A refinery is a mix of process units, pipe racks, loading areas, and tank farms. Each area has different release risk, different corrosion risk, and different noise levels. A phone that is perfect for a muster point can be wrong for a pump seal area.

Compliance comes first, but it must match the region

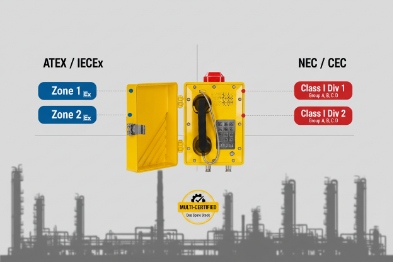

A refinery may be designed under ATEX/IECEx (Zones) or NEC Class/Division. 1 Many global projects need both, because the EPC team uses one system and the operator’s standards use another. A safe tender spec lists the expected marking style for each location and allows an equivalent approval path if the jurisdiction allows it.

Durability is a lifecycle cost, not a label

IP66/IP67 matters, but the weak points are usually the cable entry, handset cord entry, and fasteners. Hydrocarbon mist and cleaning chemicals attack seals over time. Salt fog near coastal refineries speeds up corrosion. A real “refinery-grade” build uses corrosion-resistant hardware, stable gaskets, and a cable gland solution that stays tight under vibration.

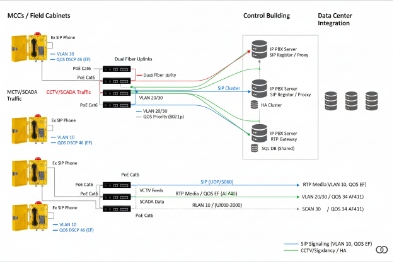

Uptime depends on the VoIP system design

A SIP phone can be certified and rugged and still fail the one job that matters, because the network drops RTP under load or the SIP proxy is a single point of failure. A refinery design should include QoS 2, voice VLANs, redundant SIP proxies, and monitoring alarms. If the phone is part of an emergency plan, it also needs a clear workflow like hotline calling and local beacon triggers.

| Requirement layer | What to request on the phone | What to request in the system design |

|---|---|---|

| Hazard compliance | Zone 1/2 or Class I Div 1/2, gas group, T-rating | Hazardous area map and mounting list |

| Environmental survival | IP66/IP67, -40 to +70°C options, corrosion strategy | Cable route, washdown and inspection plan |

| Acoustic performance | Noise-cancel mic, loud receiver, hood or headset option | Site noise survey and acceptance test |

| Integration | SIP 3, multicast, relays, PoE | PBX routing, PAGA paging plan, SCADA alarms |

| Serviceability | Replaceable handset/keypad, clear logs | Spares kit and maintenance access rules |

A refinery team that locks these layers early avoids a common trap: buying the highest Ex rating and still losing usability because audio and network were not designed for real operations.

The next sections break the same stack into the four questions procurement teams ask most often.

Which certifications do I need—ATEX/IECEx Zone 1/2, NEC Class I Div 1/2, IIC, and T-rating?

Certification is not only “ATEX yes or no.” The phone must match the exact hazardous location system used on site and the gases that may be present.

The simplest rule is this: follow the refinery hazardous area classification drawing, then select phones with markings that match each location.

Zone system vs Class/Division system

Many refineries outside North America use Zones (Zone 0/1/2). Many U.S. projects use Class I Div 1/2, sometimes with Zone language as well. A global tender often needs a compliance matrix that shows equivalency, because the purchasing team may buy equipment in one region and deploy in another.

Gas group and temperature class

Gas group and T-rating are not decorative. They reflect ignition risk and max surface temperature.

- Gas groups in common refinery work often include IIA, IIB, and IIC. IIC is the strictest gas group in that set and is often used as a conservative choice when product mix is wide.

- Temperature class 4 (T-rating) limits the equipment surface temperature. The chosen T-rating must be suitable for the ignition temperature margin of the site’s gases.

What to put in a tender pack

A clean tender request includes:

- Required marking per location (Zone 1 or Zone 2, or Class I Div 1 or Div 2)

- Gas group requirement (often IIB or IIC in refinery specs, site-driven)

- Temperature class requirement (T6 to T4, site-driven)

- Any local authority requirement (for example, a specific certificate scheme accepted by the jurisdiction)

| Site document | What it controls | What to match on the phone nameplate |

|---|---|---|

| Hazardous area classification | Zone/Division by location | Zone 1/2 or Class I Div 1/2 |

| Materials list and process risk | Gas/vapor characteristics | Gas group IIA/IIB/IIC (site-driven) |

| Ignition temperature constraints | Surface temperature limit | T-rating (T6 to T4, site-driven) |

| Jurisdiction rules | Accepted certificate scheme | ATEX 5/IECEx 6 or NEC/NRTL route |

From my experience with refinery tenders, the fastest approval happens when the vendor provides a one-page compliance matrix and a photo of the marking plate for the exact model offered.

Should I choose Ex d or Ex e, IP66/67, and 316L to survive hydrocarbons, salt fog, and -40–70°C?

Protection concept and mechanical design decide long-term survival. A refinery phone sits in hydrocarbon mist, washdown water, and sometimes coastal salt fog. Temperature swings and sun load can push internal temperatures higher than people expect.

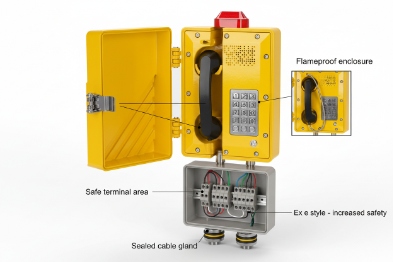

Ex d vs Ex e in practical refinery phone terms

Most refinery wall phones use protection concepts that can handle internal electronics safely in the hazardous area. Ex d 7 (flameproof enclosure) is a common route because it allows normal power levels and rugged construction. Ex e 8 (increased safety) is widely used for equipment that avoids arcs and sparks in normal operation, so it is often seen in junction boxes and terminals. For telephones, a buyer should check the exact marking and protection concept used by the product, because the internal design drives what is allowed.

A practical selection approach is:

- Use the protection concept that the certificate and marking state for the target zone.

- Do not assume Ex e alone fits a phone with active electronics unless the design and certificate clearly cover it.

IP66/IP67: demand sealing for the full assembly

IP ratings 9 are useful when they cover the full product, not only the main box. In refinery service, the common leak path is the cable entry and cord entry. A good spec calls for IP66 or IP67 at the enclosure, plus an IP-rated handset assembly and a cable gland solution that preserves the rating after installation.

316L and corrosion strategy: control the small parts

A “316L housing” helps, but offshore-style corrosion problems can still happen in refineries near the sea:

- Screws, hooks, and brackets must also be corrosion resistant.

- Mixed metals can create galvanic corrosion if not controlled.

- Coatings must protect edges and fastener holes, not only flat surfaces.

- Gaskets must resist oil mist, cleaning chemicals, and UV.

| Environment stress | What fails first in the field | Best design choice | What to request in the datasheet |

|---|---|---|---|

| Hydrocarbon mist | Swollen gaskets, sticky keys | Chemical-resistant seals | Seal material statement |

| Washdown and rain | Cable entry leakage | Certified glands + strain relief | IP rating for full assembly |

| Coastal salt fog | Rusted hooks and screws | Stainless hardware set | Hardware material list |

| -40 to +70°C | Cord cracks, gasket set | Low-temp cord and stable gasket | Operating temp for handset and cord |

If the refinery has both coastal exposure and heavy washdown, it is safer to specify corrosion-resistant hardware plus a maintenance gasket plan. That reduces field failures more than any single spec line.

How do I integrate SIP refinery phones with PAGA, DCS/SCADA, and ESD—PoE, multicast, dry contacts, and strobe relays?

Integration is where refinery phones become safety endpoints instead of isolated devices. A phone should not only place a call. It should also trigger the right alarms and report health to the control room.

SIP PBX integration: keep emergency calling simple

Refinery emergency calling should be one action:

- Lift handset and auto-call the control room, or

- Press an emergency key for hotline calling

The call should include a clear location label. The label should match the refinery tag system so operators do not waste time translating names.

Redundancy is important. A refinery should avoid a single SIP proxy or a single uplink path. Two SIP proxies or a redundant call server pair reduces outages. Phones should support primary and secondary registration and stable failover timers.

PAGA integration: multicast paging and gateways

PAGA systems vary. Some are IP-based. Some are amplifier-based with gateways.

Common integration patterns are:

- Multicast paging from SIP phones to defined paging groups

- SIP paging calls into a PAGA gateway that feeds amplifiers

- Priority rules so emergency paging wins over routine paging

QoS matters here. Multicast and RTP must be prioritized so CCTV traffic does not steal voice packets during peak events.

DCS/SCADA and ESD: dry contacts and clear alarm rules

Many refineries prefer dry contacts for safety signals because they are simple and predictable.

- A relay output can drive a strobe beacon or feed a PLC input.

- A digital input can trigger auto-dial or raise a “help point activated” alarm.

- Status outputs can show “phone fault” or “SIP offline” to the control room.

For ESD contexts, the workflow should be conservative. A phone should not trigger process shutdown by accident. Still, it can be part of the communication chain that supports safe shutdown actions.

| Integration target | Interface | What it enables | One practical rule |

|---|---|---|---|

| IP PBX | SIP | Hotline, group ring, location ID | Keep dial plan short |

| PAGA | Multicast or gateway | Area paging and muster announcements | Use priority and QoS |

| SCADA/DCS | SNMP + relays | Health alarms and event logging | Alarm only on confirmed faults |

| Beacons | Relay output | Visual indication of active call | Latch until acknowledged |

| Power | PoE 10 | Less wiring and faster install | PoE margin and surge plan |

In DJSlink projects, the highest uptime comes when the phone health state is visible in the same monitoring tools used for switches. That reduces “silent failures” in remote process areas.

Where should I install units to meet hazardous zoning and API/NFPA rules—process units, tank farms, and muster points?

Placement is the easiest way to save money and reduce compliance risk. A small move can shift a phone from a more severe zone to a less severe zone, and it can also make maintenance safer.

Use the hazardous area map as the hard boundary

A refinery should not guess zoning. The classification drawing defines where Zone 1/2 or Div 1/2 applies. The phone selection follows the drawing. When the drawing is updated, the phone list should be reviewed too.

A simple, safe placement principle is to put phones where people naturally move during stress:

- Unit entrances and egress routes

- Near control stations for local operators

- Near safe access points to process areas

- At muster points and escape routes

- At tank farm access gates and key manifolds

Avoid “too close to release sources” when possible

Refinery teams often place help points near pump seals, sampling points, loading arms, and vent sources because those are the risk points. Still, the best practice is to place the phone at the closest safe and accessible point, not on top of the highest release risk point, unless the safety plan demands it.

When a phone is placed in a harsher zone, the installation must be stricter: certified glands, correct bonding, and tight maintenance control.

Plan for usability in real conditions

A refinery is noisy. Wind can be strong. If a phone is mounted where a user cannot hear, the phone will not be used.

- Use acoustic hoods or noise control accessories in high-noise zones.

- Use clear signage and location codes.

- Ensure lighting or reflective labels help at night.

- Keep handset height consistent across the site.

| Refinery area | Typical placement goal | What to verify before final mounting |

|---|---|---|

| Process units | Operator routes and egress points | Zone boundary, noise level, access safety |

| Tank farms | Access points and manifolds | Distance to vents, washdown exposure |

| Loading racks | Near loading arms but accessible | Vehicle impact risk and signage |

| Muster points | Clear emergency contact location | Non-hazard zone if possible |

| Control room perimeter | Backup calling points | Network redundancy and UPS power |

The best commissioning habit is simple: test the full workflow at every location. A hotline call, an echo test, a beacon trigger, and a fault alarm check should be completed and logged. That is how the system earns trust in daily operations.

Conclusion

Yes, refinery Ex phones work when certification fits zoning, corrosion design fits the site, VoIP integration is redundant, and placement follows the hazardous map and emergency routes.

Footnotes

-

NEC Class/Division A hazardous location classification system used primarily in North America, distinct from the IECEx Zone system. ↩

-

QoS Quality of Service; technologies that manage network traffic to prioritize critical data like voice. ↩

-

SIP Session Initiation Protocol; a signaling protocol used for initiating, maintaining, and terminating real-time sessions. ↩

-

Temperature class A classification (T1-T6) limiting the maximum surface temperature of equipment to prevent ignition of specific gases. ↩

-

ATEX The European regulatory framework for controlling explosive atmospheres and the standards of equipment used within them. ↩

-

IECEx International certification system for equipment used in explosive atmospheres to facilitate global trade. ↩

-

Ex d Flameproof enclosure protection method; contains an internal explosion without allowing it to ignite the external atmosphere. ↩

-

Ex e Increased safety protection method; prevents arcs, sparks, or excessive heat in normal operation and specified fault conditions. ↩

-

IP ratings Ingress Protection standards defining the level of sealing effectiveness of electrical enclosures against intrusion from foreign bodies and moisture. ↩

-

PoE Power over Ethernet; technology that passes electric power along with data on twisted pair Ethernet cabling. ↩