A “waterproof” phone can still fail after cleaning. A pressure washer finds tiny gaps, then the unit fogs up, and audio gets weak.

Yes, but only if the rating matches your cleaning method. IP66 proves powerful water jets, while IPX9/IPX9K (often called IP69K) is for close-range, high-pressure, high-temperature washdown.

Match the rating to the water you actually use

What “high-pressure jets” means on real sites

People use the same words for very different tools. A fire-hose style wash is high flow but lower pressure at the nozzle. A pressure washer 1 is high pressure but often lower flow. Both can be harsh, but they attack seals in different ways.

Why one rating cannot cover every scenario

-

IP66 is built around a powerful water-jet test. It is great for storms, hose spray, and routine washdowns that are not close-range pressure washing.

-

IPX9/IPX9K is built around hot, close-range, high-pressure spray. It is aimed at industrial washdown where the nozzle is near the product.

A phone can pass IP67 immersion and still fail a jet test if the seam design is not made for spray impact. A phone can pass IP66 and still fail a pressure washer if the site uses a narrow “pencil jet” from very close.

A quick mapping that keeps specs realistic

| Your cleaning reality | What water does | Rating that proves it |

|---|---|---|

| Garden hose / rinse, normal distance | Wide spray, medium force | IP66 is usually enough |

| Strong hose jets, wind-driven rain | Fast spray hits seams | IP66 is the must-have |

| Pressure washer, close range | High local pressure, seam “peel” risk | IPX9/IPX9K (often called IP69K) |

| Hot water washdown, frequent | Heat + pressure + time | IPX9/IPX9K + corrosion spec |

If the cleaning team uses pressure washers near the unit, it is safer to treat it as an IPX9/IPX9K project, not an IP66 project.

That leads to the first buying question: which rating actually proves resistance to the jets you use?

The best answer depends on whether your “jet” is a hose or a pressure washer.

Which rating proves resistance to high-pressure jets I use?

Wrong ratings do not just cause failure. They cause tender disputes, because the supplier says “rated,” but your maintenance team says “still leaking.”

IP66 is the proof for powerful water jets in the IEC IP system. For pressure washer style cleaning, the proof you want is IPX9/IPX9K (often written as IP69K).

Use one simple question to pick the rating

Ask: “Is the nozzle ever closer than a person’s arm length, and is the spray narrow and strong?”

-

If no, the project is usually IP66.

-

If yes, the project moves toward IPX9/IPX9K.

Why IP66 is still “high jet” for many outdoor phones

IP66 uses a large nozzle and high flow. That creates a strong spray load on seams and cable entries. For outdoor phones at gates, yards, ports, and parking areas, IP66 often matches reality better than immersion ratings.

Why pressure washers push you into IPX9/IPX9K

Pressure washers create a very intense hit on a small area. That is exactly how seals get cut, lifted, or locally over-pressured. IPX9/IPX9K is designed to prove the product can take a harsh spray pattern at close distance and high pressure, often with hot water.

A clear “proof” statement you can use with buyers

| Buyer question | Short answer | What to request |

|---|---|---|

| “Can it handle hose jets?” | “That is IP66 proof.” | IP66 test report |

| “Can it handle pressure washing?” | “That is IPX9/IPX9K proof.” | IPX9 or IPX9K test report |

| “We do both.” | “We need both proofs.” | IP66 + IPX9/IPX9K evidence |

From here, the next confusion is naming. People ask for IP69, IP69K, IPX9K, and mix them in one line.

So the next step is to choose the correct wording for your tender.

Do I require IP66, IP69, or ISO 20653 IPx9K?

Specs often say “IP69” because it sounds stronger. Then vendors answer with mixed documents, and comparison becomes hard.

If you use hose jets, require IP66. If you use close-range hot high-pressure washdown, require IPX9 (IEC) or IPX9K (ISO 20653). “IP69K” is common industry language for that same harsh washdown idea.

The clean way to write it

-

For most industrial and outdoor telecom products, the base language is IEC 60529.

-

For washdown-like high-pressure hot spray, IEC uses IPX9.

-

In automotive and road-vehicle contexts, ISO 20653 uses IPX9K.

A lot of datasheets still use “IP69K” as a market shorthand. That is fine for conversation, but in a tender it is better to pin it to a test standard: IEC 60529 IPX9 or ISO 20653 IPX9K.

When ISO 20653 makes sense for a weatherproof telephone

ISO 20653 2 is common in vehicle-related environments and suppliers. If your telephone is mounted on mobile equipment, transport assets, or you follow an automotive supplier chain, ISO 20653 language can make vendor alignment easier.

Practical selection logic

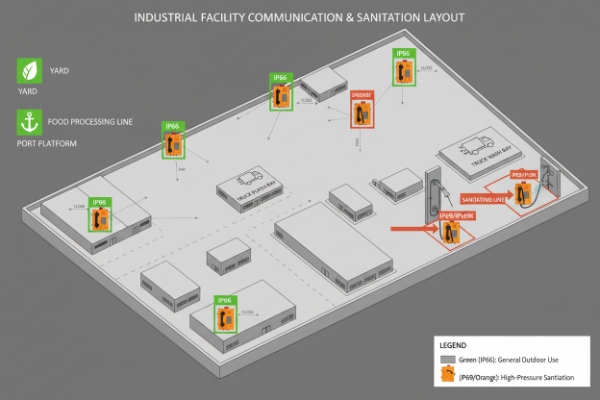

| Site type | Cleaning method | Best tender wording |

|---|---|---|

| Campus / parking / gates | Rain + occasional hose rinse | “IP66 per IEC 60529” |

| Industrial yard | Strong hose jets | “IP66 per IEC 60529” |

| Food / beverage / wash bay | Hot pressure washdown | “IPX9 (IEC 60529) or IPX9K (ISO 20653)” |

| Mixed site behavior | Jets + occasional flooding | “IP66 + IP67” or “IP66 + IPX9/IPX9K” |

If the cleaning method is clear, the next job is to specify nozzle distance and water delivery in a way that vendors can actually test.

That is where many tenders go wrong, because they invent custom numbers.

What nozzle distance and flow should I specify?

If the tender says “withstand our pressure washer,” vendors will guess. Then everyone argues after delivery.

The safest spec is to reference the standard test setup instead of making custom jet numbers. For IP66, specify the IEC 60529 IPX6 jet method. For washdown, specify IEC 60529 IPX9 or ISO 20653 IPX9K parameters.

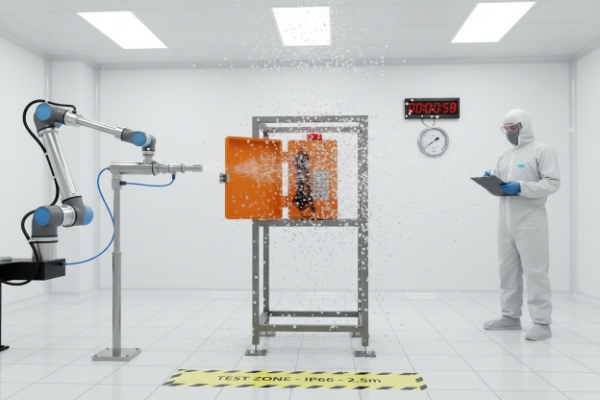

Use the standard parameters as your baseline

For IP66 (IPX6 water jets), the standard method is built around:

-

a 12.5 mm nozzle

-

100 L/min (±5%) flow

-

2.5–3 m distance

-

1 minute per m² of sprayed surface area, with a minimum 3 minutes

For IPX9 / IPX9K (high-pressure, high-temperature jets), the standard method is built around:

-

80°C water

-

8–10 MPa (80–100 bar) pressure at 0.10–0.15 m

-

14–16 L/min flow

-

spray from four angles (0°, 30°, 60°, 90°), commonly 30 seconds per angle

If you must match your exact washer profile

Sometimes your washer is harsher than the standard. In that case:

1) Keep the official requirement (IP66 or IPX9/IPX9K).

2) Add a second line called “project washdown profile” with your real pressure, nozzle type, and distance.

3) Treat that second line as an additional qualification test, not an IP claim.

A tender-ready parameter table

| Requirement | Standard reference | What to write |

|---|---|---|

| Powerful jets | IEC 60529 IPX6 | “12.5 mm nozzle, 100 L/min, 2.5–3 m, ≥3 min total” |

| Washdown jets | IEC 60529 IPX9 3 | “80°C, 80–100 bar, 14–16 L/min, 0.10–0.15 m, 4 angles” |

| Automotive washdown | ISO 20653 IPX9K | “Same core parameters, tested to ISO 20653 IPX9K” |

| Your washer reality | Project-specific | “Pressure/flow/nozzle/distance/time as used on site” |

Now, even with good specs, teams still want to do their own “quick spray test.” That can damage seals if done wrong.

So the last part is how to test jet resistance in a controlled way.

How do I test jet resistance without damaging my seals?

A careless spray test can ruin a perfectly good unit. Then the test becomes the cause of the leak, not the proof of strength.

To verify jet resistance without harming seals, use standard test settings, test dedicated samples (not every production unit), control nozzle distance and dwell time, and use non-destructive leak screening for routine QA.

Split testing into three layers

1) Design qualification (harsh, full standard test)

This is where IP66 or IPX9/IPX9K is proven. Do it on sample units. Expect that some samples may be sacrificed.

2) Production QA (non-destructive screening)

Use a fast leak screen 4 that does not stress seals the same way as a jet test. Pressure decay or vacuum-based leak checks are common for sealed enclosures. Then run full water testing only on a small sample rate.

3) Site acceptance (do not reinvent lab testing)

On-site, focus on inspection and function: correct glands, plugged unused holes, correct torque, no gasket pinch, stable audio, and clean call setup. Ask for the lab report instead of blasting the installed unit.

How to run a safer jet check when you must do one

-

Keep distance and time controlled. Do not “park” a narrow jet on a seam.

-

Use fan spray, not a pencil jet, unless your standard calls for it.

-

Maintain the mounting orientation used in real life, because water paths change with gravity.

-

Confirm the cable entry solution matches the rated configuration. Many failures start here.

-

After spray, do a dry-down period, then perform a functional call and audio check. Water in the acoustic path can make sound weak even if the enclosure is still sealed.

Post-test checks that reduce false results

| Check | What it tells you | Why it matters |

|---|---|---|

| Weight before/after | Hidden water ingress | Quick, simple indicator |

| Visual gasket line | Pinch, twist, or gap | Common assembly failure |

| Cable gland torque | Loose entry point | Top real-world leak source |

| Audio test call | Water in mic/speaker path | Real user experience check |

| Open-and-inspect (only on sacrificial samples) | True internal condition | Avoids damaging in-service units |

A weatherproof telephone can be built to pass harsh jet tests. The key is to prove it with the right standard, then avoid “creative” testing that punishes seals in unrealistic ways.

Conclusion

High-pressure jets need the right proof. Use IP66 for powerful hose jets, and IPX9/IPX9K (often called IP69K) for close-range hot pressure washdown, with controlled testing.

Footnotes

-

A mechanical sprayer that uses high-pressure water to remove loose paint, mold, grime, dust, mud, and dirt from surfaces. [↩] ↩

-

An ISO standard (Road vehicles — Degrees of protection) that defines the IP code for electrical equipment in road vehicles, including IP69K. [↩] ↩

-

The international standard (Degrees of protection provided by enclosures) that defines the IP code, including the IPX9 rating for high-pressure/steam-jet cleaning. [↩] ↩

-

A non-destructive testing method that measures the drop in pressure within a sealed component to detect leaks. [↩] ↩