Outdoor “weatherproof” phones often fail in full sun, not in rain. UV breaks plastics and inks. Heat cooks keypads, LCDs, and gaskets. A solar-load plan prevents early cracking, yellowing, and random resets.

Protect weatherproof telephones from intense sunlight by cutting solar load (shades + orientation), selecting proven UV-stable materials (UL 746C f1 where relevant), using light/IR-reflective finishes, and validating with UV aging and +70°C thermal derating tests under full sun conditions.

Sun exposure is both a UV problem and a heat problem

Sunlight damages outdoor telephones in two linked ways. UV breaks polymer chains and weakens surfaces. Heat raises internal temperatures and speeds up every aging process. In desert and tropical sites, the enclosure surface can run far above ambient because of solar gain. That extra heat then bakes the gasket line, the keypad mat, the handset cord, and the LCD window. It also increases internal pressure swings. Those pressure swings stress seals and can pull dust through weak points if the design relies on tiny gaps.

A reliable design starts with solar management. It then moves to materials that do not embrittle. Last, it proves performance with tests that match real exposure. This is important because “UV resistant” is often marketing language. It must tie to a known rating, a resin grade, and a test method.

What fails first in full sun

Keypads often stiffen or fade before housings fail. Transparent windows haze or yellow. Handset cords crack. Labels peel. Gaskets harden and take a set. Electronics can pass lab tests at +70°C ambient, but still fail in the field when the internal cavity reaches higher peaks under full sun.

| Sun-driven stress | Typical symptom | Practical countermeasure |

|---|---|---|

| UV on plastics | Yellowing, chalking, cracks | UV-stabilized resin + UL 746C f1 where needed |

| Heat soak | Random reboot, speaker distortion | Thermal derating + heat spreading + shade |

| UV on gaskets | Hardening, loss of seal | EPDM or silicone with UV/ozone resistance |

| UV on labels | Fading, peeling | Laser marking or UV-stable inks |

| Thermal cycling | Seal compression changes | Even clamp force + gasket track design |

A phone stays reliable when solar load is reduced first, then the remaining exposure is handled by materials and test validation.

Do sunshades, canopies, or north-facing mounts reduce solar load and enclosure temperature?

Direct sun is the easiest part to fix because it is external. Shade and orientation often deliver the biggest temperature drop per dollar. They also protect the surface finish and labels.

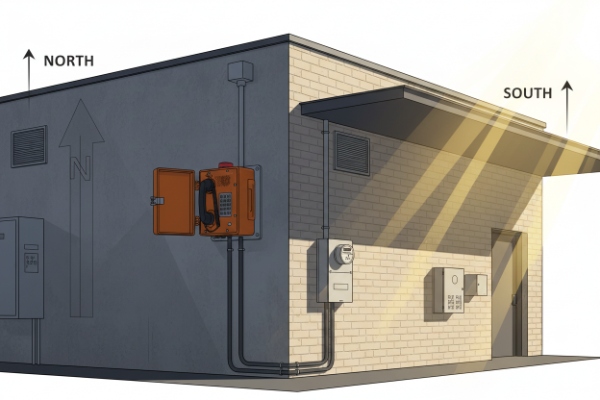

Yes. Sunshades, canopies, overhangs, and smart orientation reduce direct radiation, lower enclosure surface temperature, and reduce peak internal temperature. North-facing mounts (in the northern hemisphere) and shaded walls cut solar load during the hottest hours.

Sunshades and hoods work because they block the strongest input

A simple hood blocks direct beam radiation, which is usually the largest heat input. It also reduces UV dose on the front panel, keypad, and handset cradle. A hood should extend beyond the face so the sun cannot hit the surface at noon and again at low angles. It should also leave airflow paths so heat does not get trapped. If the hood is too tight, it becomes a heat box.

Orientation is a free upgrade

Orientation choices depend on hemisphere and site geometry. In the northern hemisphere, a north-facing mount generally sees less direct sun. East and west faces often see harsh low-angle sun that heats surfaces more because the path is long and glare is intense. Mounting under an overhang or inside a recessed niche reduces solar load without changing the unit design.

Combine shade with anti-sand thinking

In sandy sites, a hood also reduces wind-driven abrasion. It can act as a first barrier against blowing dust. The hood should avoid acting as a dust shelf. A sloped top helps sand slide off.

| Option | What it reduces | Design note for telephones |

|---|---|---|

| Hood / sunshade | Direct beam radiation + UV dose | Keep air gap, avoid sealed cavity |

| Canopy / overhang | Direct sun and rain | Ensure water does not drip into cable entry |

| North-facing mount (N hemisphere) | Midday and afternoon sun | Verify local obstacles and reflections |

| Recessed mounting | Sun and wind | Avoid deep traps that collect heat and sand |

| Reflective backplate | Wall heat transfer | Use standoff spacers to allow airflow |

What UV-stabilized materials and UL 746C f1 ratings prevent yellowing and cracking over years?

Material choice decides whether the enclosure looks and seals the same after five years. UV stabilizers and pigments matter more than the base polymer name. A “PC housing” can fail fast if the grade is wrong.

Use UV-stabilized polymer grades and finishes with proven outdoor ratings. …Where procurement requires it, specify UL 746C f1 for polymeric materials used outdoors. Pair that with UV/ozone-resistant EPDM or silicone gaskets and stainless hardware to avoid brittle seals and corroded fasteners.

Enclosures: metal is simple, polymers need the right grade

Powder-coated aluminum 1 handles UV well if the coating is outdoor-grade and applied correctly. Stainless steel resists UV by nature and stays stable under heat, but it can get hot to touch. For polymer housings, FRP (glass-filled systems) can be strong, but it still needs UV protection in the resin and a stable gel coat or topcoat. Polycarbonate and ASA blends can work, but only in UV-stabilized polymer 2 grades. In many projects, ASA or UV-stabilized PC/ASA blends are used for outdoor bezels because they resist weathering better than basic ABS.

Windows, lenses, and clear parts need special care

Clear plastics show UV damage early. If a display window is required, tempered glass resists UV and scratches. Hard-coated polycarbonate 3 can be used for impact resistance, but the coating must be outdoor rated. If the phone includes an LCD, the window and the LCD itself must be rated for the expected peak temperature, not only the ambient.

Gaskets and elastomers must match the UV and heat

EPDM 4 and silicone are common for outdoor seals. EPDM is known for weather and ozone resistance and works well in many outdoor sealing designs. Silicone keeps flexibility at higher temperatures and can be more stable in long heat soak. The gasket shape should avoid thin lips that tear when they dry out. Closed-cell structure helps keep water and dust from migrating through the material.

| Part | Good long-life choices | What to call out in spec |

|---|---|---|

| Housing | Powder-coated aluminum, stainless | Outdoor coating system + salt/UV durability if coastal |

| Polymer bezel | UV-stabilized ASA or PC/ASA | Outdoor grade + UL 746C f1 5 if required |

| Keypad | UV-stable silicone | Color stability + compression set limits |

| Seals | EPDM (weather/ozone), silicone (high heat) | Closed-cell + temperature range + UV/ozone |

| Hardware | Stainless steel | Anti-galling and consistent torque |

| Labels | Laser mark or UV-stable print | Fade resistance + abrasion resistance |

UL 746C f1 is useful when a customer wants a recognizable outdoor polymer benchmark. Still, field success comes from specifying the exact resin grade and confirming test data, not only a label.

Should light-colored coatings, IR-reflective paint, or heat sinks be specified for ≥900 W/m² sites?

High irradiance sites amplify every weakness. Light color reduces absorption across visible wavelengths. IR-reflective coatings go further by reducing near-infrared absorption, which can be a major heat source. …Heat sinks and spreaders help move heat away from hotspots and reduce internal peak temperatures.

For ≥900 W/m² locations, specify light or “cool” coatings with high solar reflectance, consider IR-reflective paints, and add heat spreading where the design allows. Pair these with shading first, because shade reduces solar load more than any coating alone.

Coatings: white is not the only answer, but reflectance matters

Light colors usually lower surface temperature because they absorb less. …Some “cool roof” style pigments reflect near-infrared even in darker colors. That can help if a customer demands a specific color for branding. A practical way to write the requirement is by solar reflectance [^6] and thermal emittance targets, not just “paint it white.” If a spec only says “light gray,” suppliers will interpret it in many ways.

Heat spreading can protect electronics

A metal backplate can act as a heat spreader. Internal aluminum plates can move heat from power components into the housing. Still, uncontrolled heat sinks 6 can create hot-to-touch surfaces. For public-facing telephones, surface temperature limits can matter. The design must balance electronics safety and user touch safety.

Do not forget cable and handset materials

Cables and cords in sun often crack before housings fail. Outdoor-rated jackets and UV-stable cord materials reduce early failures. If the handset is black rubber, it will get very hot. A lighter handset or a shaded cradle can reduce user complaints and cord aging.

| Method | Benefit in ≥900 W/m² | Risk | Best use |

|---|---|---|---|

| Sunshade | Largest temperature drop | Poor design traps heat | First choice |

| Light color | Lower absorption | Dirt shows more | Outdoor industrial sites |

| IR-reflective coating | Lower heat even in darker colors | Cost and supplier control | Branding-sensitive projects |

| Heat spreader plate | Lowers internal hotspots | Hot-to-touch surfaces | Industrial sites with touch control |

| Vent + membrane | Reduces pressure and heat buildup | Must stay dust-tight | Dusty + hot sites with proper venting |

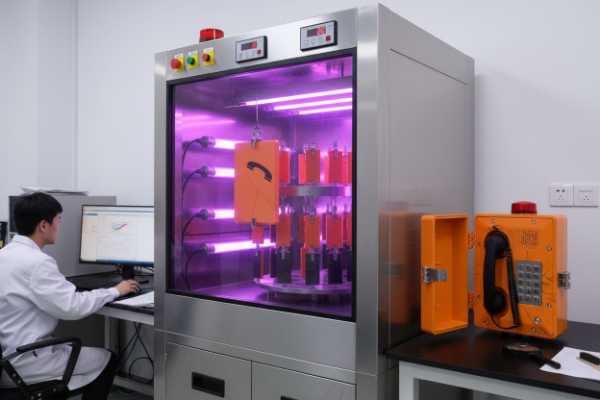

Are UV aging tests (ISO 4892/ASTM G154) and thermal derating proven at +70°C under full sun?

Testing is where many projects either become solid or become risky. UV aging standards and thermal tests can be useful, but only if the acceptance criteria are tied to function. A housing can look fine and still lose seal compression. A keypad can still “work” but become stiff and fail user acceptance.

Yes, when tests link to real acceptance criteria. Use ISO 4892 or ASTM G154 for UV exposure of plastics, coatings, legends, and gaskets, then verify function after aging. Pair that with thermal derating and sun-load testing that simulates full sun at +70°C ambient, including internal peak temperature measurement and performance checks.

UV aging tests must include the weak parts

A good UV plan tests more than the housing. It includes keypad mats, handset cords, gaskets, display windows, and printed legends. After UV cycling, checks should include: color change, surface chalking, crack inspection, tensile and elongation change for elastomers, and compression set for gaskets. A seal that takes a set will leak even if the housing looks perfect.

Thermal derating should be based on internal peak, not only ambient

A spec that says “works at +70°C ambient” can still fail under sun because internal air may exceed that. The correct approach measures internal hotspots during a representative sun-load condition. Then electronics, battery (if any), LCD, and audio parts must be thermal derating 7 so they remain within their own limits at that internal peak. Audio performance should be checked at temperature because speaker compliance and mic sensitivity can shift.

Combine tests into a realistic qualification package

A realistic qualification combines UV exposure, thermal soak, and functional checks. It also checks sealing after exposure, because UV and heat together can change gasket elasticity. For long-term deployments, add a simple torque retention check to confirm that fasteners stay tight after cycling.

| Test item | Standard method | What to verify after test |

|---|---|---|

| Plastic/coating UV aging | ISO 4892 8 / ASTM G154 9 | Color shift, chalking, cracks, adhesion |

| Gasket aging | UV + heat cycling | Compression set, elasticity, sealing continuity |

| Legend durability | UV + abrasion | Readability, peel resistance |

| Thermal soak under sun | Sun-load simulation + +70°C ambient | Internal peak temp, no reboot, audio stable |

| Seal integrity | IP dust/water check after aging | No leakage, door closes fully, gasket not cut |

Conclusion

Intense sunlight protection is simple when done in order: shade and orientation first, UV-stable materials next, reflective finishes and heat spreading after, then prove it with UV aging and full-sun thermal derating.

…Footnotes

-

Details the durability and corrosion resistance of powder coating for aluminum in outdoor environments. ↩

-

A comprehensive guide to plastics that withstand ultraviolet radiation and weathering. ↩

-

Technical study on the effective temperatures and weathering of polycarbonate glazing in desert conditions. ↩

-

Explains why EPDM rubber is highly resistant to UV radiation and suitable for outdoor seals. ↩

-

Defines the UL 746C F1 rating for plastic materials used in outdoor electrical enclosures.[^6]: Describes Solar Reflectance Index (SRI) and how it measures a material’s ability to stay cool in the sun. ↩

-

Overview of heat sink technology and how it dissipates thermal energy from electronic components. ↩

-

Explains the concept of derating power supplies and electronics to ensure reliability at high temperatures. ↩

-

Information on ISO 4892 standards for accelerated weathering testing of plastics using lab light sources. ↩

-

Details the ASTM G154 standard for operating fluorescent light apparatus for UV exposure of nonmetallic materials. ↩