Extreme cold weather can have a significant impact on weatherproof telephone seals, leading to potential performance issues. When exposed to low temperatures, elastomer seals can stiffen, which reduces their ability to compress properly and may eventually cause leaks. Let’s dive into the details of how elastomers perform in cold conditions and how to mitigate these issues.

Yes, extreme cold can cause weatherproof telephone seals to harden and lose elasticity, resulting in compromised sealing and the potential for leaks.

As the temperature drops, elastomers used in weatherproof telephone seals, such as rubber, silicone, and EPDM, experience changes in their flexibility. This leads to stiffening, reduced compression ability, and an increased risk of leakage. Understanding the materials’ behavior under extreme cold conditions and implementing proactive measures can help ensure the seals’ effectiveness in harsh environments.

What Elastomers Perform Well Below −40°C?

In extremely cold conditions, elastomer seals need to retain their flexibility to provide a reliable seal. Many common elastomers stiffen and lose their elasticity at low temperatures, but some perform better than others in such conditions.

EPDM and silicone elastomers are more resilient at temperatures below 0°C, retaining better elasticity and sealing properties compared to other materials.

EPDM (Ethylene Propylene Diene Monomer)

EPDM rubber 1 is known for its excellent resistance to low temperatures, withstanding temperatures as low as −50°C to −60°C without losing its flexibility. This makes it a popular choice for weatherproof seals used in outdoor applications, including weatherproof telephones. However, its performance can vary depending on its formulation, and it may still experience some stiffening under extreme cold.

Silicone Elastomers

Silicone is another elastomer that performs well in cold environments, with a low glass transition temperature 2, which means it retains its flexibility at temperatures as low as −55°C. Silicone rubber 3 is often used for applications where low-temperature performance is critical, including seals for outdoor telephones. However, silicone may be more expensive than other elastomers and may not always be the best choice for every application.

Other Cold-Resistant Elastomers

In addition to EPDM and silicone, certain specially formulated cold-resistant elastomers can perform well at temperatures below −40°C. These materials, such as fluoroelastomers and polyurethane 4, are designed to remain flexible and functional in extremely cold conditions, but they may come with higher costs or other trade-offs in terms of chemical resistance or durability.

How Do Freeze–Thaw Cycles Affect the Long-Term Performance of Seals?

Repeated freeze-thaw cycles can have a negative impact on weatherproof seals, especially in environments with fluctuating temperatures. During freeze-thaw cycles, tiny amounts of moisture can seep into the seal area. When the temperature rises, this moisture can expand, leading to gradual damage to the seals. Over time, the repeated stress from freeze-thaw cycles can cause the elastomer to crack or lose its elasticity.

Freeze-thaw cycles can weaken the seal material over time, leading to cracking, brittleness, and loss of sealing performance.

The Impact of Moisture and Expansion

The small amounts of moisture that enter the seal during freeze-thaw cycles 5 can cause the elastomer to expand and contract repeatedly. This gradual movement stresses the material, causing it to crack or break down. This is especially true for materials like EPDM and silicone that are more prone to damage under moisture exposure.

Preventing Long-Term Damage

To minimize the impact of freeze-thaw cycles, it’s essential to use elastomers with low moisture absorption properties. Seals can also be designed to include barriers to moisture or insulation to reduce the temperature fluctuations experienced by the seal. Additionally, regular maintenance and inspection of seals can help detect early signs of damage, allowing for timely replacements before the seal fails.

Can Cold-Weather Performance Be Enhanced with Design Modifications?

Yes, the cold-weather performance of weatherproof seals can be enhanced through thoughtful design modifications. These modifications can help mitigate the risks posed by extreme temperatures and ensure the longevity and effectiveness of the seals.

Designing for consistent compression, using materials with low temperature flexibility, and replacing aged seals can significantly improve the performance of weatherproof seals in extreme cold.

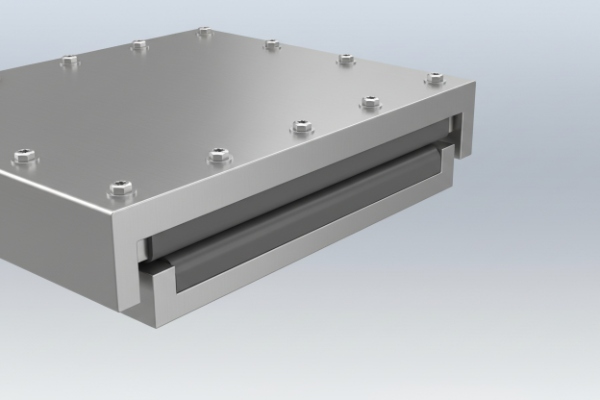

Consistent Compression

When designing seals for extreme cold environments, it’s crucial to ensure even compression across the entire seal surface. This can help prevent gaps that could allow moisture or cold air to enter. Uneven compression can lead to localized stiffening of the elastomer, which might cause failure in specific areas. Proper design helps maintain consistent sealing performance across the seal and extends its service life.

Selecting the Right Durometer

Choosing the correct durometer hardness 6 of elastomer is also essential. Seals made from overly hard materials may not compress effectively at low temperatures, leading to potential leaks. Using a softer, more flexible material can help maintain the seal’s performance, but the material must still be durable enough to handle wear and tear.

Regular Replacement of Aged Seals

Even with the best materials and designs, seals can degrade over time. Elastomers can age and crack due to UV exposure, mechanical stress, or the repeated impact of freeze-thaw cycles. Regular inspections and timely replacement of aged or damaged seals can prevent the seal from failing in extreme temperatures.

What TR10 and Compression Set Results Are Documented for Low-Temperature Elastomers?

TR10 and compression set are two important factors to consider when evaluating elastomers for use in cold environments. TR10 refers to the temperature at which a material’s elasticity begins to decrease significantly, and compression set refers to the permanent deformation a material undergoes after being compressed.

TR10 and compression set results are critical in determining the long-term viability of elastomers in cold conditions.

TR10 Values

For elastomers like silicone, TR10 values 7 are typically well below −40°C, making them suitable for use in very cold environments. Silicone elastomers can maintain flexibility at temperatures as low as −50°C to −55°C, which is ideal for outdoor applications where extreme cold is common.

Compression Set Results

The compression set 8 results for elastomers in cold conditions vary by material. Silicone and EPDM generally perform well, with minimal compression set even after exposure to extreme cold and freeze-thaw cycles. However, some elastomers may experience significant compression set after prolonged exposure to cold, which could compromise the seal’s ability to maintain a tight fit.

Are Cold-Chamber Validation Reports Available for Weatherproof Seals?

Yes, cold-chamber validation reports are often available for weatherproof seals, particularly those designed for use in extreme cold environments. These reports typically test the performance of seals under controlled low-temperature conditions to evaluate their elasticity, compression set, and overall sealing ability.

Cold-chamber testing can provide valuable insights into the long-term performance of weatherproof seals under cold conditions.

What Cold-Chamber Testing Involves

Environmental chamber testing 9 involves exposing seals to low temperatures for extended periods, followed by monitoring their performance in real-world conditions. This helps manufacturers assess how well the seals maintain their functionality, and whether they are likely to stiffen, crack, or fail under long-term cold exposure.

How Reports Help in Material Selection

By reviewing cold-chamber validation reports, manufacturers and engineers can make informed decisions about which elastomers to use in weatherproof telephone seals. These reports provide data on TR10, compression set, and other critical factors that influence the performance of seals in extreme cold, ensuring that the selected materials will perform reliably in the target environment.

Conclusion

Extreme cold can significantly impact the performance of weatherproof telephone seals, causing them to harden, lose flexibility, and eventually fail. By selecting the right materials, designing for consistent compression, and conducting accelerated weathering testing 10, businesses can ensure their seals maintain their effectiveness in harsh cold environments.

Footnotes

-

Explains the properties of EPDM rubber, highlighting its resistance to weathering and low temperatures. ↩

-

Defines the glass transition temperature, the point where a polymer turns brittle in cold. ↩

-

Detailed catalog on silicone rubber properties, including low-temperature flexibility. ↩

-

Discusses the use of polyurethane in insulation and sealing, noting its cold-weather applications. ↩

-

Explains the mechanics of freeze-thaw cycles and their damaging effects on materials. ↩

-

Guide to the Shore Hardness Scale (Durometer), critical for seal compression selection. ↩

-

Explains the TR10 test method for determining the low-temperature retraction of rubber. ↩

-

Parker O-Ring Handbook, a comprehensive guide to sealing materials and compression set data. ↩

-

Overview of environmental test chambers used to simulate extreme cold conditions for product validation. ↩

-

Describes ASTM G154 testing, used to simulate weathering effects on non-metallic materials. ↩