Coastal air eats hardware quietly. Screws rust, heads seize, and doors stop sealing. Then one loose hinge turns an IP66 phone into a repair ticket.

Protect fasteners with the right stainless grade or proven marine coatings, block galvanic couples to aluminum, and seal every joint with washers, caps, and controlled torque so salt cannot sit and creep.

A corrosion plan that keeps IP66 and field uptime

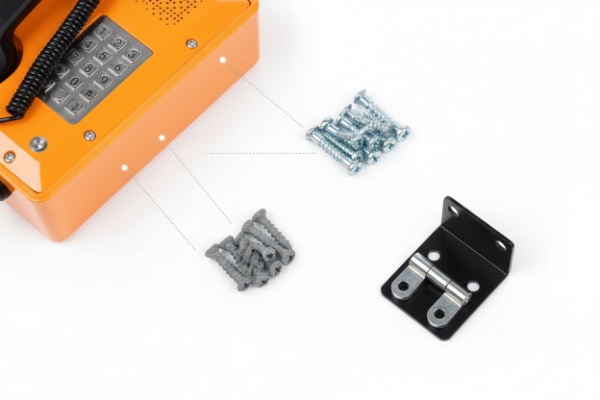

Fasteners are often the first part to fail on an outdoor telephone, even when the housing looks perfect. In coastal sites, the air carries chlorides. Salt settles into screw recesses and hinge gaps. It stays wet longer than most people expect. The joint becomes a small salt bath. Corrosion then starts in three common ways: surface rust on low-grade hardware, crevice corrosion under washers and in threads, and galvanic corrosion when stainless meets aluminum in a salty electrolyte.

The easiest way to stop this is to treat fasteners as a system, not a line item. The system has four parts: base material, coating, joint design, and assembly discipline. Base material means choosing stainless that resists pitting, not only “stainless” by name. Coating means matching the site class and exposure, not only copying a generic outdoor screw. Joint design means stopping water pooling and giving salt nowhere to hide. Assembly discipline means torque control, thread protection, and traceability so the BOM is the same in year three as it was in the first approval.

From the supplier side, the best projects also define what “pass” looks like. It is not enough to say “marine grade.” A strong specification lists the stainless grade or coating type, the expected environment class, and the checks used for incoming inspection. It also defines how to avoid stainless galling and how to keep threads serviceable after months of salt spray.

What should be matched to the site

- Salt level and wet time (open coast, splash zone, industrial coast)

- Housing material (aluminum, stainless, GRP)

- Access frequency (service doors opened monthly or yearly)

- IP sealing strategy (gasket compression and screw pattern)

| Site exposure | Main fastener risk | Best default choice | Notes for long life |

|---|---|---|---|

| General outdoor | Tea staining, loosening | A2/304 1 + sealing washers | Keep joints dry and clean |

| Coastal air (C4/C5 style) | Pitting, crevice corrosion | A4/316 2 or 316L | Control crevices and use isolation to aluminum |

| Warm marine + heavy wetting | Pitting at heads and threads | Duplex stainless 3 for key hardware | Focus on hinges, brackets, and external screws |

| Chemical coast (salt + pollutants) | Underfilm corrosion | Duplex or coated systems | Add protective topcoat and avoid water traps |

The next sections answer the four decisions that matter most: which stainless grade fits coastal work, which coatings make sense for C4/C5-type expectations, how to stop galvanic corrosion with aluminum or GRP, and what sealing and thread practices keep IP66 stable in salt spray.

If these details are locked early, fasteners stop being the weakest link.

Which fastener materials suit coastal sites—A4-316, 316L, or duplex stainless?

Coastal sites punish “almost marine” hardware. A screw can look fine for months, then pit at the head and seize in the thread. The next service visit becomes drilling and rework.

A4-316 is a strong default for most coastal installations, 316L is best when parts are welded or heat-affected, and duplex stainless is the safer choice for high-chloride, warm, or constantly wet joints like hinges and brackets.

A4-316 as the practical baseline

A4-316 fasteners are widely used for marine environments. They resist chlorides better than 304/A2. For many weatherproof telephones installed near the coast but not in direct splash, A4-316 is enough when the joint is designed well. It also has good availability in common screw sizes. If a project needs higher strength, A4-80 4 is often used instead of a weaker stainless grade.

The main limit is pitting and crevice corrosion when salt stays trapped under a washer or inside a recessed head. Stainless does not “rust like carbon steel,” but it can pit. Pitting starts small and then grows. It is more likely in warm climates and in wet crevices that do not dry.

Where 316L helps

316L has lower carbon. That reduces the risk of sensitization and intergranular corrosion after welding. Most screws are not welded, so 316L is not always necessary for every fastener. It becomes more relevant for welded hinge parts, welded brackets, and fabricated stainless assemblies where heat-affected zones exist. For a hinge leaf or bracket that is welded and then exposed to salt, 316L is usually the safer call.

When duplex stainless earns its cost

Duplex stainless (often used in marine and chemical service) has higher resistance to chloride attack and often higher strength. For weatherproof telephones, duplex is most valuable where failure is expensive: door hinges, mounting brackets, top-exposed fasteners that stay wet, and any place where crevice corrosion is likely. Duplex can be harder to source in small screw sizes and may increase cost. A good compromise is to use duplex for brackets and hinges, and use A4-316 for general screws, while improving sealing and isolation to aluminum.

| Part location | Wetness and chloride exposure | Suggested material | Reason |

|---|---|---|---|

| External housing screws | Medium to high | A4-316 | Good baseline marine resistance |

| Hinges (moving, crevice-prone) | High | Duplex or 316L/316 with strong design | Crevice corrosion risk is high |

| Brackets near wall runoff | Medium to high | Duplex or 316L | Runoff keeps salts wet |

| Internal screws | Low | A2/304 or coated steel | Cost control without risk |

| Grounding points | Medium | 316 / tinned copper interface | Keep electrical path stable |

A simple rule helps buyers: choose the highest grade where water sits and moves. Choose the practical grade where joints stay dry and service is easy.

What coatings meet ISO 12944 C4/C5-M for screws, brackets, and hinges?

Coatings fail when people treat them like paint on a flat panel. Screws have threads, recesses, and sharp edges. Salt attacks those edges first.

For C4/C5-M style expectations, use stainless where possible, and use proven corrosion coating systems where steel is needed: zinc-nickel with topcoat, zinc-flake systems with sealer, or duplex paint systems on brackets and hinges.

Screws: stainless first, coatings when stainless is not possible

In many weatherproof telephone builds, stainless screws are the cleanest solution. They avoid underfilm corrosion problems and keep appearance stable. Coated carbon steel screws can work when strength or cost forces that route, but the coating system must be chosen carefully. Thin zinc plating alone is not enough for coastal sites. Better options include zinc-nickel plating with a passivation layer and a topcoat, or zinc-flake coatings 5 with a sealer. Zinc-flake systems are popular because they can perform well in salt environments and reduce hydrogen embrittlement risk compared with some electroplated methods.

Brackets and hinges: treat them as structural corrosion items

Brackets and hinge assemblies may be larger parts with welded seams and cut edges. For these parts, duplex coating systems are common in harsh environments. A typical approach is a strong primer plus a UV-stable topcoat. When the bracket is steel, a robust primer system plus topcoat is often easier to control than trying to rely on plating alone. When the bracket is aluminum, a good pretreatment plus powder coat can perform well, but edges must be rounded and film build must be controlled.

How to write a coating requirement that is practical

ISO 12944 6 is often used as an environment language. Still, fasteners themselves are not usually qualified only by that label. A workable procurement spec asks for coating type, minimum thickness, and corrosion test evidence on representative parts. It also defines acceptance around a scribe or at edges, because those are real failure points in the field.

| Hardware type | Best base approach | Coating option if not stainless | Notes for coastal durability |

|---|---|---|---|

| Screws and bolts | A4-316 | Zn-Ni + topcoat or zinc-flake + sealer | Avoid thin zinc-only plating |

| Hinges | Duplex stainless or 316L | Duplex paint system on steel hinge | Protect pin and crevices |

| Mounting brackets | Aluminum + powder coat, or duplex stainless | Hot-dip galvanize + paint, or primer + topcoat | Round edges, seal joints |

| Small brackets inside phone | A2/304 or coated steel | Zn-Ni | Lower wet exposure |

For most buyers, the simplest path is still stainless outside and coated steel inside. That keeps costs controlled and removes the worst corrosion risks.

How is galvanic corrosion avoided between stainless fasteners and aluminum/GRP housings?

A4-316 screws can still cause damage if they are bolted straight into bare aluminum. Stainless is more noble than aluminum. In salt water, aluminum becomes the sacrificial metal.

Avoid galvanic corrosion by isolating stainless from aluminum with nonconductive washers and sleeves, keeping the aluminum coated or anodized, sealing the joint to block electrolyte, and designing drainage so salt cannot stay in the interface.

Understand the galvanic couple in the real joint

Galvanic corrosion 7 needs three things: two different metals, electrical contact, and an electrolyte. Coastal environments provide the electrolyte. Stainless-to-aluminum is a common couple because stainless fasteners are used on aluminum housings. The problem is worst when the joint stays wet and salt-rich. It is also worse when the stainless area is large compared with the aluminum area. In practice, even small screws can create visible aluminum corrosion around the head if water pools.

GRP housings behave differently. GRP itself is not a metal, so galvanic corrosion does not happen in the GRP material. Still, there can be inserts, backing plates, or embedded metal threads. Those metal parts can create their own couples. GRP can also trap moisture around inserts if the design has pockets.

Isolation is often the cleanest fix

Isolation breaks electrical contact. Nylon, PEEK, or fiber washers under heads and insulating sleeves in through-holes can reduce galvanic current. A sealing washer can also help by blocking water. For threaded inserts in aluminum, using a coated thread, a barrier paste, or a nonconductive thread sealant can reduce the electrolyte path.

Use barriers and drainage, not only “better metal”

A coating on aluminum acts as a barrier. Anodizing can also help. A topcoat must remain intact at the hole edge. That is why edge radius and careful drilling are important. Drainage matters too. If the screw sits on a top surface where salt water pools, corrosion will happen faster no matter how good the materials are. A small design change, like moving screws off horizontal surfaces or adding a cap head cover, can reduce wet time.

| Risk area | Why it corrodes | Best prevention | Simple design habit |

|---|---|---|---|

| Stainless screw on bare aluminum | Strong galvanic couple | Insulating washer + coated aluminum | Never leave bare aluminum at holes |

| Recessed screw head pocket | Traps salty water | Cap + seal + drainage path | Avoid deep pockets on top faces |

| Through-bolt with aluminum bracket | Large wet interface | Sleeve + barrier paste | Use nonmetal spacer where possible |

| GRP insert area | Moisture trap, crevice corrosion of insert | Seal insert, avoid water pockets | Use sealed inserts and smooth geometry |

In coastal deployments, galvanic control is as important as choosing A4-316. Many failures blamed on “bad stainless” are actually wet galvanic joints.

Should sealing washers, threadlock, and anti-seize be specified to preserve IP66 in salt spray?

A phone can have the right screws and still lose its IP rating when joints loosen or seize. Salt builds inside the head recess. Technicians then strip heads or leave screws under-torqued.

Yes. Specify sealing washers to block water at the head, use threadlock to hold torque under vibration, and use the right anti-seize to prevent stainless galling—without contaminating gaskets or creating new galvanic problems.

Sealing washers do two jobs

A sealing washer stops water from entering around the screw shank. It also reduces crevice wetting under the head. For outdoor telephones, bonded sealing washers (metal washer with an EPDM seal) are common. The washer material should match the fastener to avoid a new corrosion pair. The elastomer should resist UV and ozone. EPDM often works well outdoors. Silicone can work too, especially at high heat. The washer should not be over-compressed, or it will extrude and lose seal.

Sealing caps on exposed screw heads also help. They stop salt from filling the recess. They also reduce tool damage during maintenance.

Threadlock keeps gasket compression stable

IP66 performance depends on gasket compression. If screws loosen from vibration or thermal cycling, compression drops and leaks start. A medium-strength threadlocker 8 can stabilize clamp load. Still, threadlock must be compatible with the plastics and elastomers in the joint. It must also be usable with stainless. Some teams use patch-applied threadlock on screws to control quantity and avoid mess.

Anti-seize prevents galling, but choose the right type

Stainless-on-stainless threads can gall, especially under high torque. Anti-seize 9 reduces that risk and keeps screws serviceable after salt exposure. For joints involving aluminum, avoid copper-based anti-seize because it can promote galvanic issues and leave conductive residue. A PTFE-based or non-metallic anti-seize is often safer for stainless into aluminum threads. Nickel-based anti-seize can be used in high-temperature cases, but it should still be evaluated for the housing material and the service environment.

Assembly discipline is the hidden requirement

Sealing washers and compounds do not work if torque is random. A strong spec includes torque values, a tightening sequence for multi-screw doors, and a clear rule on reuse. In coastal sites, replacing external fasteners at planned intervals can be cheaper than emergency repairs.

| Item | What it protects | Best practice spec line | Common mistake |

|---|---|---|---|

| Sealing washer (bonded) | Water path at screw head | Stainless washer + EPDM seal, controlled compression | Over-tightening until seal extrudes |

| Threadlocker | Clamp load and gasket compression | Medium strength, patch if possible | Too much liquid, contaminates gasket |

| Anti-seize | Prevents galling and seizure | PTFE/non-metallic for stainless-aluminum joints | Copper paste on aluminum assemblies |

| Screw head cap | Blocks salt accumulation | UV-stable cap, easy to replace | Ignored until recess fills with salt |

| Torque control | Keeps IP66 stable | Defined torque + sequence + verification 10 | “Hand tight” field assembly |

For coastal weatherproof telephones, these small details often decide whether the unit stays sealed and serviceable after years of salt exposure.

Conclusion

Use A4-316 or duplex where wetting is high, apply marine-ready coating systems when steel is needed, isolate stainless from aluminum, and seal and control threads to keep IP66 stable.

Footnotes

-

Explains the difference between A2 (304) and A4 (316) stainless steel grades, highlighting A4’s superior corrosion resistance. ↩

-

Compares 304 and 316 stainless steels, detailing why 316 is the standard for marine applications due to molybdenum content. ↩

-

An overview of duplex stainless steels, known for their high strength and excellent resistance to stress corrosion cracking. ↩

-

Technical data on A4-80 stainless steel fasteners, offering higher tensile strength than standard A4-70. ↩

-

Describes zinc flake coating technology, which provides cathodic protection and high corrosion resistance without hydrogen embrittlement. ↩

-

Details the ISO 12944 standard for corrosion protection of steel structures by protective paint systems. ↩

-

A comprehensive guide to galvanic corrosion, its causes, and prevention methods. ↩

-

Explains how threadlockers work to prevent fastener loosening due to vibration and thermal expansion. ↩

-

Overview of anti-seize compounds and their role in preventing galling and corrosion in threaded connections. ↩

-

Best practices for ensuring proper fastener torque to maintain joint integrity and seal compression. ↩