Windblown sand can destroy a “weatherproof” telephone fast. It slips into gaps, grinds seals, and ruins audio. A dust-tight plan stops it before damage starts.

Protect desert-deployed weatherproof telephones by starting with dust-tight (IP6X) hardware, then stacking heat-stable gaskets, correct cable glands, and dust-rated acoustic membranes. Add a hood, choose abrasion and UV resistant materials, and keep a simple inspection routine to preserve sealing for years.

Desert sand is a system problem, not a single seal

Desert sand does not “attack” one weak point. It attacks every edge at the same time. Wind drives abrasive particles at high speed. Heat expands housings in the day and shrinks them at night. That cycle changes gasket compression and can open micro-gaps. Fine dust also rides pressure changes. When a sealed box heats up, the air inside expands. When it cools, it pulls air back in. If the only “breathing” path is a tiny crack, the crack becomes the dust pump.

Map the sand paths first

A tough enclosure still fails if the entry points stay unmanaged. In desert deployments, these are the usual sand paths: door seams, keypad borders, handset cradles, speaker and mic ports, and cable entries. A dust-tight rating (IP6X 1) matters because it forces the design to block all dust, not just “most dust.” IP66 2 adds strong water-jet resistance, which often improves seam design and fastener strategy too. Still, the real win comes from treating the phone as a sealed system with controlled openings.

Build a “sealing stack,” not a single barrier

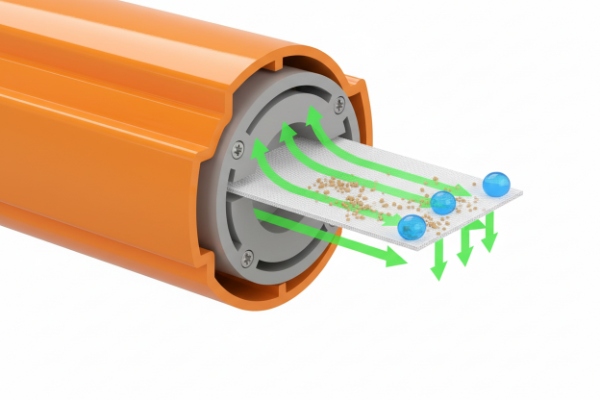

The best designs layer defenses. A primary gasket blocks dust at the main seam. A secondary lip or labyrinth slows airflow and traps grit before it reaches the gasket line. Proper cable glands 3 stop sand from tracking along the cable jacket. Acoustic membranes [^4] let sound out without leaving an open hole. A pressure-equalization vent 4 reduces the urge for air to move through bad places. Each layer reduces the load on the other layers.

Verify the design under desert-like stress

Lab IP tests help, but desert stress adds abrasion, UV, and long heat soak. Field feedback matters. A simple sand-and-wind checklist can reveal where grit collects and where doors stop closing fully. Small changes like adding a hood, rotating the mounting face away from prevailing wind, or changing gland orientation can double service life.

| Attack path | Typical failure mode | What works in deserts |

|---|---|---|

| Door seam | Gasket gets cut by grit, compression becomes uneven | Closed-cell EPDM/silicone gasket + even clamp force + gasket track cleaning |

| Cable entry | Sand tracks along sheath into enclosure | Correct-size cable gland + strain relief + drip loop + unused holes plugged |

| Speaker/mic port | Open mesh clogs or leaks dust | Acoustic membrane + protected recess + serviceable filter option |

| Handset cradle | Grit prevents full latch, leaves a gap | Tight cradle fit + wear pads + easy cleaning access |

| Fasteners | Loosen over thermal cycles | Thread-lock strategy 5 + torque spec + stainless hardware |

Sand protection becomes easier when the problem gets split into four decisions: sealing methods, audio vents, materials, and long-term mounting and maintenance.

Which IP6X/IP66 sealing methods prevent dust ingress in desert deployments?

Desert wind turns every tiny gap into a sand nozzle. If the enclosure relies on “close fit,” sand will win. A real IP6X/IP66 sealing approach removes the guesswork.

Use dust-tight enclosure geometry, then apply closed-cell EPDM or silicone gaskets with even compression, sealed keypads, and sealed cable entries. Treat every penetration as a designed interface, not a hole.

Start with enclosure geometry that helps the gasket

A gasket cannot compensate for a warped door or an uneven flange. In OEM projects, the best results come from a stiff housing and a flat, continuous sealing land. …A gasket groove or track helps in two ways. It holds the gasket in place, and it keeps grit from sliding across the sealing line during closing. A simple overlap seam (a small “step” or “lip”) also reduces direct wind pressure on the gasket.

…Choose gaskets that stay flexible in heat

Heat is the silent gasket killer. Some foams harden, take a set, and stop sealing. Closed-cell EPDM 6 and silicone remain more stable across high temperatures and long sun exposure. Closed-cell matters because it resists water and dust migration through the gasket body. A good gasket design also needs the right compression. Too little compression leaks. Too much compression accelerates permanent set and makes doors hard to close. Even compression matters more than “thicker gasket.” Use multiple fasteners or a continuous clamp design to avoid high-pressure points that cut the gasket with trapped grit.

Seal interfaces people touch every day

Keypads, hooks, and handset cradles get more abuse than any door seam. Desert grit can sit in recesses and act like sandpaper each time someone presses a key. A sealed keypad mat with molded sealing ribs works well because it reduces edge gaps. For service doors, use captive screws or a hinged cover so technicians do not drop fasteners into sand and then “borrow” the wrong screw length later.

Cable entries and unused holes decide success

Many “IP phones” fail at the cable. Sand loves to track along the sheath into a gland that does not match the cable OD. Choose glands with the correct clamping range, and tighten them to spec. Add dust caps for unused glands and use blind plugs for unused holes. Route cables downward and create a drip loop so wind-driven dust and rain do not sit at the entry.

| Sealing element | Where it belongs | Desert-specific note |

|---|---|---|

| Closed-cell EPDM gasket | Main door seam | Good heat stability, resists dust pumping |

| Silicone gasket | High-heat areas, frequent access doors | Stays flexible, higher cost but reliable |

| Labyrinth / overlap seam | Door and cover edges | Reduces direct sand blast at gasket line |

| O-rings | Push buttons, rotary parts, connectors | Needs correct groove design and lubrication |

| Correct-size cable gland | Cable entry | Match cable OD, add strain relief and dust caps |

| Conformal coating 7 (optional) | PCB protection | Helps if dust ever gets in during service events |

Do ePTFE vents, acoustic meshes, and filters maintain audio while blocking sand?

Audio ports feel like a forced compromise. Leave them open and sand enters. Seal them completely and the phone sounds muffled. The fix is to control the opening, not remove it.

Yes, when used correctly. ePTFE vents handle pressure equalization, while acoustic membranes and meshes protect speaker and mic paths. Choose dust-rated parts, protect them from direct blast, and design for clogging and easy service.

Separate “breathing” from “talking”

A pressure-equalization vent and an acoustic port do different jobs. A vent prevents pressure swings from pulling dust through weak seams. It should sit in a sheltered area, away from direct sand blast. An acoustic port must pass sound with low loss, so it needs a membrane that balances airflow and acoustic transparency. When a design uses one opening for both jobs, it often fails. A dedicated ePTFE vent for breathing plus a dedicated acoustic membrane for audio usually performs better.

Use membranes as engineered parts, not “screen doors”

A simple metal grill blocks rocks but not fine dust. In deserts, a mesh alone often becomes a dust trap. A better approach uses a layered structure: a protective outer grill, then an acoustic membrane (often ePTFE-based or similar), then an inner cavity shaped to reduce direct impact. Many membranes include hydrophobic and oleophobic treatments, so they resist moisture and dirt sticking. That helps audio stay clear longer. Still, every filter can clog. The design should keep the membrane area large enough so partial clogging does not kill volume.

Design for clogging and cleaning

Desert maintenance teams will clean with what they have. Some will use compressed air, which can push dust deeper. It helps to create a recessed port that can be brushed and vacuumed. If a replaceable filter cartridge fits the design, it can reduce downtime. A simple “inspection window” and a spare membrane kit can save a site visit.

| Option | What it does | Audio impact | Desert risk | Best practice |

|---|---|---|---|---|

| ePTFE vent (pressure equalization) | Balances internal pressure | None, if separate from audio path | Clogs if exposed | Place under hood, use splash shield |

| Acoustic membrane | Passes sound, blocks dust and water | Low loss if sized well | Can clog over time | Use larger area, avoid direct blast |

| Stainless mesh only | Physical protection | Good at first | Fine dust passes and also accumulates | Use only as outer guard |

| Replaceable filter pad | Captures dust upstream | Can reduce high frequencies | Needs service | Make replacement easy and cheap |

| Labyrinth audio channel | Reduces direct entry | Slight resonance change | Traps grit if too tight | Add clean-out access, avoid sharp turns |

What materials and coatings resist abrasion, UV, and high heat under blowing sand?

A phone can be perfectly sealed and still fail because sand erodes the surface, UV cracks plastics, and heat warps parts. In deserts, material choice is not a style decision. It is reliability.

Use abrasion and UV resistant housings like powder-coated aluminum or stainless, UV-stabilized polymers for bezels, and stainless hardware. Pick finishes that resist chalking, and avoid plastics that become brittle in long heat and sun.

Housing materials that survive sand blasting

Blowing sand acts like continuous micro-blasting. Powder-coated aluminum 8 works well when the coating system resists UV and chalking. A thicker, high-quality powder coat helps because it delays base metal exposure. Stainless steel (often 316 for coastal-desert mixes) resists corrosion and holds up under abrasion, but it adds weight and cost. FRP (fiberglass-reinforced plastic) can also work if the resin system and UV protection stay strong, but sharp edges and thin walls can chip under impact.

Coatings and surface details matter as much as base material

A good coating system resists UV fade and stays smooth so sand does not “grab” the surface. Dark colors can increase surface temperature under sun, so a lighter color and a sunshade can reduce thermal stress. For labels and legends, use UV-stable printing or laser marking. For windows and lens parts, tempered glass 9 resists scratches better than many plastics, but it can shatter under impact. Hard-coated polycarbonate can be a good compromise when impact risk is high.

Small parts fail first

Keypads and handset contact points take constant wear. Silicone rubber keypads hold up well in heat, but they still need good UV resistance and a design that avoids grit traps. Hardware should be stainless, and threads should resist loosening under thermal cycling. Cable jackets should resist UV and abrasion too. PUR and high-grade outdoor-rated jackets usually perform better than basic PVC in long sun exposure.

| Part | Recommended material/finish | Why it works in deserts | Watch-outs |

|---|---|---|---|

| Main housing | Powder-coated aluminum or stainless steel | Abrasion resistance, structural stability | Ensure coating quality, avoid thin edges |

| Fasteners | Stainless steel hardware | Resists corrosion, holds torque | Use anti-galling strategy |

| Keypad | UV-stable silicone rubber | Heat tolerance, good sealing geometry | Design to avoid grit pockets |

| Window/lens | Tempered glass or hard-coated polycarbonate | Scratch resistance or impact resistance | Choose based on vandal vs sand risk |

| Cable jacket | Outdoor-rated PUR or equivalent | UV and abrasion resistance | Match gland range to cable OD |

| Labels/legends | Laser mark or UV-stable ink | Reduces fading and peeling | Avoid cheap stickers in full sun |

Which mounting and maintenance practices ensure long-term sealing—height, cable glands, gasket checks?

A strong product can still fail if a site mounts it where sand piles up, or if no one checks seals after the first year. The desert punishes small mistakes over time.

Mount above sand drift zones, protect the face with a hood, route cables with drip loops, and standardize gasket and gland checks. Clean grit from gasket tracks so doors close fully, and replace worn seals before leaks start.

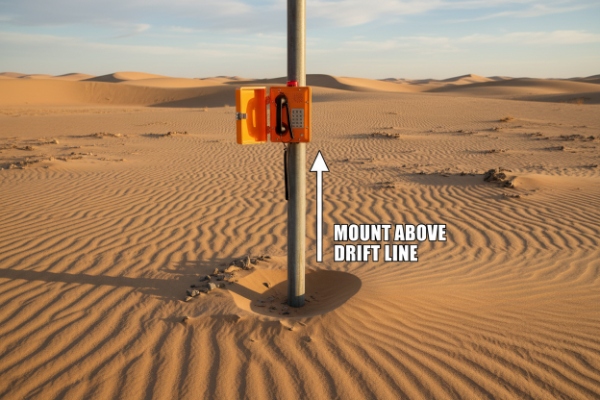

Mounting position controls the sand load

Sand moves like water. It forms drifts, dunes, and eddies behind obstacles. Mounting slightly off the ground reduces exposure to the thickest sand cloud near the surface. It also reduces the chance of burial during storms. Many sites do well when the unit sits at normal user height, while the base stays clear of drift lines. Orientation matters too. If possible, face the unit away from prevailing wind or mount it on the leeward side of a structure. A hood or sunshade reduces direct impact and also lowers temperature spikes on the front panel.

Cable management prevents “hidden leaks”

Cable glands should point downward when possible, and the cable should form a drip loop before it reaches the gland. That loop reduces water and dust tracking. Conduit can help, but only if the conduit entry stays sealed. If installers pull too hard on the cable, the gland seal can deform. Strain relief 10 protects the gland and keeps the cable OD stable where it seals.

Maintenance keeps gaskets working

Desert maintenance is not about frequent full servicing. It is about a quick, repeatable check. Grit in the gasket track can hold a door slightly open. That creates a constant leak path. A simple routine works: open the door, vacuum and brush the track, wipe the gasket, then close and torque to spec. Replace gaskets that look flattened, cracked, or shiny from abrasion. For acoustic ports, clean the outer grill gently, and avoid blasting air straight into the port.

| Practice | How often | What to do | What it prevents |

|---|---|---|---|

| Visual gasket check | Quarterly | Look for cuts, flattening, grit buildup | Slow leaks and “dust pumping” |

| Gasket track cleaning | Quarterly or after storms | Brush + vacuum, then wipe | Doors not closing fully |

| Cable gland inspection | Quarterly | Check tightness, cracking, dust caps | Sand tracking into enclosure |

| Hood/sunshade inspection | Twice per year | Confirm fasteners, no cracks | Direct sand impact and heat spikes |

| Audio port cleaning | Quarterly | Brush outer grill, inspect membrane | Muffled audio from clogging |

| Torque re-check | After first month, then yearly | Re-torque cover fasteners | Loosening from thermal cycles |

Conclusion

Desert reliability comes from dust-tight design, heat-stable seals, protected audio membranes, tough materials, and simple maintenance. Stack these steps, and sand becomes manageable.

…Footnotes

-

Explains the testing process and strict requirements for a dust-tight enclosure rating. ↩

-

Details the protection level against high-pressure water jets and dust ingress. ↩

-

Technical overview of mechanical cable entry devices for sealing and retention.[^4]: Describes breathable vents that allow air passage while blocking water and dust. ↩

-

Discusses materials and methods for balancing internal enclosure pressure to prevent seal failure. ↩

-

Information on chemical threadlockers to prevent fastener loosening from vibration or thermal expansion. ↩

-

Highlights the aging, ozone, and weather resistance properties of EPDM rubber sponge. ↩

-

Guide to protective polymeric films for printed circuit boards against harsh environments. ↩

-

Outlines the durability and corrosion resistance benefits of powder coating metal surfaces. ↩

-

Compares the safety and strength differences between tempered and regular glass. ↩

-

Explains the importance of relieving stress on cables to prevent damage. ↩