A handset can look tough and still fail after one wet shutdown wash. Water enters, audio drops, and the “emergency phone” becomes a decoration when the plant needs it most.

A waterproof handset for an explosion-proof telephone should combine Ex-safe construction with strong sealing, shock resistance, wide temperature range, and clear audio near machines. Materials, gaskets, and cable retention must match oil, salt, and chemicals on site.

The core design goals of a waterproof Ex handset

A waterproof handset in a hazardous area has one job: keep a reliable voice path under abuse. That sounds simple, but the handset lives at the edge of many risks. Hands get wet and oily. Gloves scrape surfaces. Operators drop the handset. UV and salt attack plastics. Cable pulls happen during rush moments. The phone may sit outdoors for years with little use, then must work on the first press.

A good handset design starts with three goals:

Keep the sealing stable for years, not only on day one

A true waterproof handset needs sealing in multiple places: the speaker cavity, microphone cavity, key interfaces (if present), cord entry, and the hook area. A high IP label means nothing if the gasket shrinks, cracks, or takes a compression set after thermal cycling. In my experience, the long-term winner is a design that uses simple seal geometry, solid compression surfaces, and materials that do not swell in oil.

Keep audio intelligible under noise, wind, and water film

A handset near machinery needs more than a “loud” receiver. It needs a receiver that stays clear at high volume and a microphone path that rejects noise. A wet environment also adds a water film risk over ports. The acoustic design should protect the transducers from direct water pressure while keeping voice bandwidth clear.

Keep the mechanical system serviceable

Large plants do not want full device replacement for a cord issue or a cracked hook. A service-friendly handset uses replaceable cords, standard glands, and parts that can be swapped with basic tools under a work permit.

| Design target | What it protects | What to specify in procurement |

|---|---|---|

| Long-term sealing | Water, dust, washdown ingress | IP rating plus gasket material and aging approach |

| Rugged handling | Drops, impacts, glove use | IK rating, hook strength, cord strain relief |

| Clear voice | High noise, wind, wet surfaces | Noise reduction mic, high-SPL receiver, sidetone tuning |

| Easy maintenance | Downtime, spare planning | Field-replaceable cord and handset module options |

A handset that meets these goals feels boring in the best way. It does its job for years. The next step is to turn these goals into checkable ratings and numbers.

If the rating line is wrong, the rest does not matter. So the first detailed question should always be about ingress, impact, and temperature.

Which ingress, impact, and temperature ratings should a hazardous-area handset meet—ATEX/IECEx, IP66/IP67, IK10, –40°C to +70°C?

A handset can pass a bench test and still fail outside. The plant does not care about a lab story. The plant cares about rain, washdown, and cold mornings.

A harsh-site handset should meet the same safety concept as the full telephone. The handset itself is usually part of the certified product, not a random accessory. That is why Ex marking alignment matters first. After that, the durability ratings give confidence that the handset will keep working.

Ex safety alignment comes first

The handset must be compatible with the explosion protection concept used by the telephone. In many projects, the safest path is to use the handset that ships as part of the certified phone configuration. If a site wants a replacement handset, the replacement should be the same certified part number, or a vendor-approved equivalent that keeps the same Ex conditions of use 1.

This point sounds strict, but it avoids trouble. If a handset change affects surface temperature, impact sparks, or sealing interfaces, the certification story becomes messy.

IP66/IP67 gives a practical waterproof baseline

For water and dust, IP66 and IP67 2 are common project targets:

- IP66 supports heavy water jets and harsh wash

- IP67 supports temporary immersion scenarios, which can happen during flooding or cleaning mistakes

The key is to confirm what the IP rating covers. Some vendors test the full phone body but not the handset-cord interface. The procurement line should state “handset and cord assembly” when the plant is serious about washdown.

IK10 reduces crack and drop risk

IK ratings 3 help when handsets are dropped or hit against metal structures. IK10 is a common “industrial rugged” target because it helps limit breakage from impacts. A cracked handset body is not only a cosmetic issue. It can destroy sealing and expose internal parts.

–40°C to +70°C matches many outdoor and industrial sites

A wide temperature range matters for oil fields, mines, and cold storage edges. –40°C to +70°C is a common target when the handset may live outdoors. It also protects the gasket and cord from becoming stiff, then cracking.

| Rating / target | Typical requirement level | Why it matters for the handset |

|---|---|---|

| Ex compliance | ATEX 4/IECEx 5 aligned with phone | Keeps the handset within the certified build |

| Ingress | IP66 or IP67 | Washdown, rain, dust, temporary immersion |

| Impact | IK10 | Drop resistance, vandal resistance |

| Temperature | –40°C to +70°C (or site-defined) | Outdoor stability, gasket and cord life |

Many buyers stop here and assume the handset is “done.” It is not done. The next failure point is usually audio. A phone that survives water but cannot be heard near machines still fails the real mission.

Do noise-cancelling microphones and high-SPL receivers ensure 85–95 dB intelligibility near machinery?

A loud plant creates a simple problem: the operator cannot hear. The phone then becomes a stress device. People shout. The call gets worse. The message gets lost.

A good handset for hazardous areas should support clear audio at high ambient noise. Noise-cancelling microphones and high-SPL receivers help a lot, but they work only when the whole acoustic chain is designed well.

“85–95 dB” is a site reality, not a marketing line

Many industrial areas run near 85 dB. Some zones are louder. The handset should deliver high receiver sound pressure level 6 (SPL) while keeping distortion controlled. A high-SPL receiver is useful, but it needs clean amplification and stable power, especially with long cable runs and PoE power budgets.

Noise-cancelling microphones reduce outgoing noise, not incoming noise

A noise-cancelling microphone 7 helps the far end hear the speaker. It does not solve the local user’s hearing problem. For local hearing, the receiver output level and clarity matter most. For far-end hearing, the mic pattern, port design, and DSP settings matter.

Acoustic port protection must not block voice bandwidth

Waterproof designs often use acoustic membranes or labyrinth paths. These parts protect against water jets and dust. Still, they can also reduce high-frequency clarity if they are not tuned well. That is why a vendor should show voice tests, not only SPL numbers.

Practical specs to request

A strong procurement request for an Ex handset audio system includes:

- Receiver sound pressure level at a defined distance and frequency band

- Microphone sensitivity and noise rejection description

- Echo control and sidetone tuning approach for handset mode

- Test notes under high ambient noise, not only quiet-room tests

| Audio feature | What it improves | What to ask the vendor to state |

|---|---|---|

| High-SPL receiver | Local intelligibility near machinery | SPL level, distortion limit, usable bandwidth |

| Noise-cancelling mic | Far-end understands the speaker | Mic type, pattern, DSP method, wind handling |

| Acoustic membrane | Keeps water and dust out | Material, IP support, impact on frequency response |

| Sidetone control | Speaker comfort and clarity | Adjustable or fixed sidetone behavior |

In real deployments, audio success comes from balance. Too much volume creates distortion and fatigue. Too much noise suppression can clip speech. The best handset is not the loudest. It is the clearest under stress.

Once audio is clear, the next concern is long-term survival. Harsh sites attack plastics, metals, and seals in ways that lab tests often miss.

What materials and seals resist oil, salt-fog, and chemicals, and how do cords and glands support strain relief maintenance?

A handset can meet IP and still fail after months of oil mist. A cord can pass a pull test and still crack at low temperature. Materials decide the real lifespan.

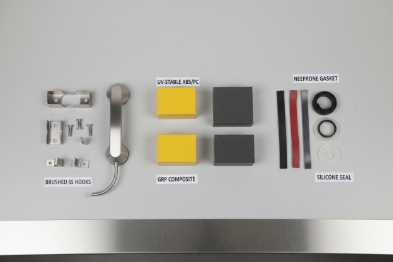

A reliable waterproof Ex handset uses corrosion-resistant metals, UV-stable polymers, and gaskets that keep elasticity after oil and heat exposure. Cable retention also needs a complete approach: coiled cord or armored umbilical, correct gland, and real strain relief.

Materials: choose what survives the site chemistry

For hooks and external hardware, stainless steel is a common choice because it resists corrosion and keeps strength. Hooks are abused. A weak hook breaks the retention chain and increases drop events.

For handset bodies, UV-stable polymers 8 like ABS or similar industrial blends can work well when properly formulated. Some sites prefer heavier materials because they feel solid, but weight also increases drop energy. The best result often comes from a balanced polymer body with a strong internal frame.

Seals: neoprene vs silicone is a real decision

Gaskets and strain relief boots live under compression for years. Neoprene can resist many oils well. Silicone can handle wide temperature swings and stays flexible in cold. The best choice depends on the site’s oils, fuels, and cleaning chemicals. A vendor should be able to name the gasket material and provide compatibility guidance.

A key detail is compression set 9. If a gasket takes a permanent set, IP falls over time. Thermal cycling makes this worse. That is why a handset should be designed with enough gasket “travel” and stable compression surfaces.

Cords: coiled, straight, or armored umbilical

Coiled cords reduce trip hazards and keep slack controlled. They also concentrate stress near the ends, so end boots and strain relief design matter. Straight cords can be simpler and may last longer if routed cleanly.

Armored umbilicals add mechanical protection and can improve resistance to cuts and abrasion. Still, armored systems require correct bonding and correct gland selection. A weak gland defeats the armor value.

Ex-certified glands and strain relief are part of the handset spec

The handset cord entry should use an Ex-certified gland 10 system or a vendor-approved retention method. The goal is simple: prevent cable pull from reaching the internal terminations. A good design also makes cord replacement possible without replacing the whole phone, when the certification and service process allow it.

| Component | Recommended choices | What problem it prevents |

|---|---|---|

| Hook and exposed hardware | Stainless steel | Corrosion and mechanical breakage |

| Handset housing | UV-rated industrial polymer, reinforced structure | UV cracking, impact damage, seal distortion |

| Gaskets | Neoprene or silicone (site-matched) | Oil swell, cold cracking, compression set |

| Cord style | Coiled for control, armored for harsh abrasion | Trip hazards, cuts, pull damage |

| Gland and strain relief | Ex-compatible, correct clamp range | Cable pull-out, seal failure, downtime |

A maintenance plan should treat cords as consumables in some sites. A spare cord kit and a clear replacement method keep uptime high. For large deployments, standardizing on one handset and one cord system across areas reduces training and reduces wrong-part installs.

Conclusion

A waterproof Ex handset needs the right Ex alignment, IP/IK and temperature targets, clear high-noise audio, chemical-resistant materials, and a serviceable cord-and-gland system for long-term uptime.

Footnotes

-

Ex conditions of use Specific operational limitations mandated by certification to ensure safety in hazardous locations. ↩

-

IP66 and IP67 Ingress Protection ratings defining resistance to powerful water jets (66) and temporary immersion (67). ↩

-

IK ratings International numeric classification for the degrees of protection provided by enclosures against external mechanical impacts. ↩

-

ATEX The European Union framework for controlling explosive atmospheres and the standards of equipment used within them. ↩

-

IECEx International electrotechnical commission system for certification to standards relating to equipment for use in explosive atmospheres. ↩

-

receiver sound pressure level A measure of the acoustic volume output capability of the handset speaker. ↩

-

noise-cancelling microphone A microphone designed to filter out ambient noise to improve voice clarity for the listener. ↩

-

UV-stable polymers Plastic materials formulated to resist degradation and cracking from long-term exposure to sunlight. ↩

-

compression set The permanent deformation of a material (like a gasket) after being compressed for a period of time. ↩

-

Ex-certified gland A cable entry device certified to maintain the explosion-proof integrity of the enclosure it enters. ↩