One wrong Ex detail can block commissioning. The phone may power on, but the site auditor can still stop the job.

IECEx compliance for an explosion-proof telephone requires the correct protection concept (Ex d/e/ib), correct marking (EPL, group, T-class, Ta), the right IECEx documents (CoC, ExTR, QAR), and certified accessories like glands and stopping plugs installed per IEC 60079-14/17.

IECEx compliance for Ex telephones is a matching exercise, not a logo

IECEx covers “what the product is” and “how it must be used”

IECEx is a global certification system 1 built around IEC standards for explosive atmospheres. For telephones, IECEx proves the device design and production controls match specific protection methods. It also sets limits for installation and maintenance. Those limits are not optional. Many phones fail acceptance because the product is certified but the entry hardware and cable method are wrong.

A practical view is to treat IECEx as three layers:

-

Design layer: enclosure, terminals, PCB safety, creepage and clearance, temperature behavior, and mechanical integrity.

-

Manufacturing layer: controlled production, inspections, traceability, and ongoing quality assessment.

-

Field layer: correct selection for Zone and group, correct cable entries and glands, correct maintenance and inspection behavior in hazardous industrial environments 2.

Explosion-proof telephones often combine concepts. A typical industrial build uses Ex d for the main housing, Ex e for the terminal chamber, and Ex ib for certain I/O circuits. Each concept brings different rules for cable glands, terminations, and servicing.

Zones and EPL guide selection

In IEC language, the “Zone” describes area risk. The EPL (Equipment Protection Level) describes the equipment’s protection level. They work together. If the site is Zone 1 gas, the product must be suitable for that risk level, usually shown by an EPL like Gb and the correct protection concept and gas group. For dust, Zone 21 usually links to Db with dust group and dust surface temperature marking.

Write the requirements like a checklist

Most EPC and offshore specs become clear when they are written as “must match” items. This is how many projects are controlled in tender and inspection.

| Requirement item | What it must match | Why it matters in the field |

|---|---|---|

| Hazard type | Gas (G) and/or Dust (D) | Gas and dust have different marking rules |

| Zone | Zone 1/2 and/or 21/22 | Controls allowable EPL and concept |

| Protection concept | Ex d, Ex e, Ex ib, Ex t (dust) | Controls entry, wiring, and maintenance |

| Group | IIC for gas, IIIC for dust (if required) | Controls severity of ignition risk |

| Temperature | T-class (gas) or max surface °C (dust) | Prevents hot surface ignition |

| Ambient range | Ta min/max | Marking is only valid inside Ta range |

A good IECEx purchase does not stop at the phone body. It includes the correct glands, stopping plugs, and thread plan in the same scope. That keeps the installation clean and audit-ready.

If the goal is a phone that passes inspection and stays reliable for years, the next sections explain the protection methods, marking, documents, and accessory rules in practical terms.

Which IEC 60079 protection methods apply—Ex d, Ex e, Ex ib—and how do they impact design and maintenance?

Harsh sites often assume “Ex d fixes everything.” That assumption creates mistakes at terminals, glands, and maintenance steps.

Ex d contains an internal ignition, Ex e prevents arcs and hot spots through robust construction, and Ex ib limits energy for intrinsically safe circuits. Each method changes the allowed wiring, entry hardware, and what technicians can do during maintenance.

Ex d: flameproof enclosure changes how you open and seal

Ex d (often written as Ex db in newer notation) relies on a flameproof enclosure and flamepaths. The enclosure can contain an internal explosion and cool escaping gases through the flamepath. For a telephone, that typically means a heavy metal housing and controlled joints. Maintenance must respect this. Covers must not be modified. Flamepaths must stay clean and undamaged. Fasteners must be the correct type and torque. The phone often cannot be opened in the hazardous area while energized unless site procedures and the protection concept allow it.

Ex e: increased safety is common in terminal chambers

Ex e (often Ex eb) is designed to avoid arcs, sparks, and dangerous temperatures in normal operation. Many explosion-proof telephones use Ex e in the terminal compartment because it is easier and safer for terminations. This affects the cable gland choice. Ex e glands are common for Ex e chambers, but they must match the certificate conditions. Terminations must keep conductor strands controlled. Cable jacket strip length matters. Loose strands and poor ferrules can create heat and tracking risks.

Ex ib: intrinsic safety usually applies to I/O and accessories

Ex ib is an intrinsic safety level commonly suitable for Zone 1 intrinsically safe circuits 3 when applied correctly. In telephones, Ex ib is often used for low-energy external circuits like inputs, outputs, or headset interfaces, depending on model design. Ex ib changes how external devices can connect. It may require barriers or isolators and strict entity parameter matching. Maintenance becomes easier because Ex i circuits can be worked on live under controlled conditions, but only if the whole circuit is designed and installed as Ex i.

A simple maintenance impact matrix

| Protection method | What it protects against | What changes in maintenance | What installers often miss |

|---|---|---|---|

| Ex d (db) | Internal ignition containment | flamepaths and fasteners must be preserved | wrong stopping plug or damaged threads |

| Ex e (eb) | Avoid ignition sources by construction | terminations and clearances are critical | wrong gland type or poor ferruling |

| Ex ib | Energy limitation | barriers/isolators and parameters must match | mixing IS and non-IS wiring in the same path |

A safe project uses the protection methods exactly as the certificate intends. The best practice is to treat the phone as a certified assembly, not as a box that can accept any cable method. When this is followed, maintenance becomes predictable and inspection goes faster.

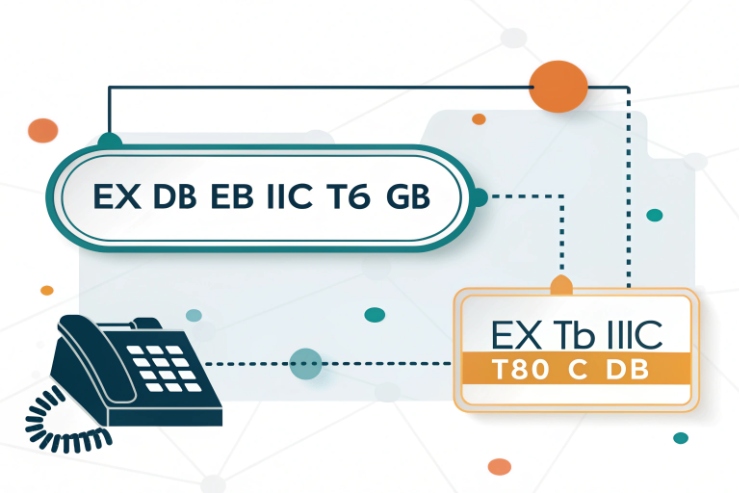

How should IECEx markings be read—equipment group, EPL, gas/dust group, temperature class, and ambient range?

Many teams read only “Ex” and “Zone 1.” That shortcut hides the most important limits.

Read IECEx marking in a fixed order: protection concept, EPL, gas or dust group, temperature class or max surface temperature, and Ta ambient range. The marking tells where the phone is allowed and under what conditions.

Step 1: Identify the protection concept string

The marking usually includes one or more concepts, such as Ex db, Ex eb, Ex ib, or Ex tb for dust by enclosure. Combined markings are common because the phone may have different protection approaches for different parts. The marking is a map of design intent. It also tells you which installation rules apply.

Step 2: Confirm EPL matches the site risk

EPL ( Equipment Protection Level 4 ) is often shown as:

-

Ga / Gb / Gc for gas

-

Da / Db / Dc for dust

A phone for Zone 1 gas typically aligns with Gb. A phone for Zone 2 gas often aligns with Gc. For dust, Zone 21 aligns with Db, and Zone 22 aligns with Dc. This is the practical way inspectors think. If the EPL is lower than the zone needs, the phone is not acceptable.

Step 3: Match gas and dust group severity

Gas group often appears as IIA, IIB, or IIC. Dust group often appears as IIIA, IIIB, or IIIC. Offshore and chemical sites often demand IIC and IIIC because they are the more severe groups used in many specifications. If the site dossier states IIC, a phone marked only for IIB is not a substitute.

Step 4: Check temperature class and Ta together

Gas uses a T-code like T4, T5, or T6. Dust often uses a maximum surface temperature in °C, like T85°C, because dust ignition is handled differently. The key point is this: the temperature marking is only valid inside the specified ambient range Ta. A phone can be “T6” at Ta up to +40°C and become “not T6” outside that limit. This matters for tank farms, deserts, and cold regions.

A field-friendly marking checklist

| Marking element | What question it answers | What to copy into the project spec |

|---|---|---|

| Ex db / eb / ib / tb | How ignition risk is controlled | required protection concepts |

| Gb/Gc or Db/Dc | Which zone risk it supports | required EPL |

| IIC / IIIC | Which hazard severity | required group |

| T4–T6 or T°C | Max surface temperature | required temp class/value |

| Ta range | Valid ambient conditions | Ta min/max requirement |

When the marking is read this way, selection becomes simple. The phone either matches the site or it does not. This is also the easiest way to align purchasing, site HSE, and installers, because everyone is looking at the same short list.

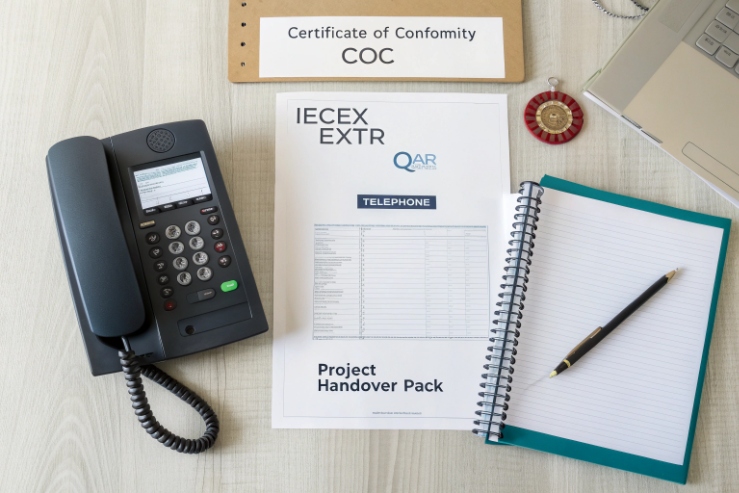

What documents are required—IECEx CoC, ExTR, QAR, and installation manual per IEC 60079-14/17?

A site can reject a shipment even when every phone is correctly marked, if the document set is incomplete or inconsistent.

The core IECEx document set includes the IECEx Certificate of Conformity (CoC), the ExTR test report reference, the QAR for manufacturing quality assessment, and a clear installation and maintenance manual aligned with IEC 60079-14 and IEC 60079-17 practices.

IECEx CoC: the public-facing certificate that drives acceptance

The IECEx CoC is usually the first document end users check. It states the certified model, the protection concepts, and the marking. It also includes certificate conditions and any “special conditions” that must be followed. The nameplate and datasheet must match this document. If they do not, the site inspector will stop the job until it is resolved.

ExTR: the technical evidence behind the certificate

The ExTR is the technical test report used to support the CoC. End users do not always request the full ExTR, but serious projects often request at least the ExTR reference and key extracts that affect installation, such as:

-

allowed entry types and thread forms

-

allowable cable gland types and limitations

-

temperature and Ta limits

-

any limitations on external circuits and I/O

This prevents “hidden conditions” from appearing late.

QAR: proof that production stays consistent

The QAR shows that the manufacturer’s quality system and processes are assessed for IECEx production. quality assessment 5 is vital for long-life assets. Offshore owners care that the phone shipped today matches the phone shipped next year. A QAR-backed production flow supports traceability and controlled change management.

Installation and maintenance manuals: where most compliance is won or lost

IEC 60079-14 and IEC 60079-17 guide installation and inspection/maintenance practices for Ex equipment. In procurement terms, the manual must clearly tell installers:

-

what entry hardware is permitted

-

how to maintain IP sealing while keeping Ex compliance

-

torque guidance and safe opening rules

-

inspection points for flamepaths, gaskets, and terminals

-

what to check after service

A document checklist that fits real EPC workflows

| Document | Minimum content to request | Why the project needs it |

|---|---|---|

| IECEx CoC | certificate number, marking, model list | primary compliance evidence |

| ExTR reference/extract | key conditions and limitations | prevents installation surprises |

| QAR | current QAR reference | production consistency proof |

| Installation manual | entry methods, gland rules, torque notes | correct site installation |

| Maintenance/inspection notes | checks per service cycle | safe long-term operation |

When these documents are available and consistent, FAT and SAT become faster. The site team can validate compliance without chasing information across emails. That is where projects save weeks.

Do IP/IK ratings, cable glands, and thread types need matching IECEx approvals for Zone 1/2 and 21/22?

Many failures in the field come from one small part: the gland. A certified phone can become non-compliant because an installer used a “similar” gland from stock.

Yes. Cable glands, stopping plugs, and adapters must be certified and suitable for the same protection concept and zone. Thread types must match the enclosure entries, and the final build must keep required IP and mechanical strength, especially for dust zones where enclosure protection is part of safety.

Cable glands and stopping plugs must match the protection method

If the phone has Ex d entries, the gland must be suitable for Ex d service and the cable type. If the phone has an Ex e terminal chamber, the gland must be suitable for Ex e and must maintain the required clearances and sealing. If the project uses Ex i circuits, the wiring method must follow Ex i rules, and the entry hardware must still match the enclosure concept.

Stopping plugs are not “just plugs.” They must be certified for the correct protection concept and thread. A wrong plug can damage threads, reduce engagement, or violate certificate conditions.

Thread types are part of the certified design

Ex enclosures often use specific thread standards and engagement lengths. Mixing metric and NPT by force is a common site mistake. It damages threads and creates leak paths. It also creates nonconformity because the enclosure entry no longer matches the certified condition.

A compliant project locks these details:

-

entry thread type and size per phone model

-

approved gland models per cable outer diameter range

-

approved stopping plugs and reducers, if any

-

material selection for corrosion, such as 316L in marine zones

IP and IK are not “IECEx by default,” but they still matter

IECEx focuses on explosion protection. IP and IK are environmental durability ratings. mechanical protection 6 is critical in dust zones where Ex t relies on enclosure protection to prevent dust ingress. Even in gas zones, IP66/67 often defines suitability for wash-down and storms. IK protects the phone from impact that can break seals or expose internal parts.

A smart spec treats IP and IK as mandatory site fitness requirements and verifies that glands and cable jackets do not reduce them.

A practical accessory and enclosure matching table

| Item | What must match | Typical offshore/refinery best practice |

|---|---|---|

| Cable gland | Ex type + cable OD + zone | certified gland, 316L where needed |

| Stopping plug | Ex type + thread | certified plug, correct torque |

| Adapter/reducer | allowed by certificate | avoid if possible, use approved only |

| Cable jacket | chemical and UV exposure | oil-resistant, UV-stable jacket |

| Shield bonding | EMC method and safety bonding | 360° termination where specified |

| IP/IK target | site environment | IP66/67 and IK10 where required |

A reliable installation keeps the phone compliant and reduces rework. The best practice is to include glands and plugs in the phone delivery scope, not as “installer supply.” This makes the installation repeatable across crews and across assets.

Conclusion

IECEx compliance needs the right Ex concept, clear marking, complete CoC/ExTR/QAR documents, and certified glands and industrial safety standards 7 threads installed per IEC 60079-14/17, while preserving IP and mechanical durability.

Footnotes

-

The official portal for the IECEx global certification system for equipment used in explosive atmospheres. ↩ ↩

-

Learn about OSHA’s safety regulations and standards for hazardous industrial environments in the oil and gas sector. ↩ ↩

-

A technical overview of intrinsically safe circuits and their role in preventing ignition in hazardous zones. ↩ ↩

-

An essential guide to understanding Equipment Protection Level (EPL) markings for hazardous area equipment. ↩ ↩

-

Understanding the processes of quality assessment and assurance to ensure consistent manufacturing and product reliability. ↩ ↩

-

Detailed information on the IP Code system for evaluating ingress and mechanical protection of electronic enclosures. ↩ ↩

-

A comprehensive overview of international industrial safety standards governing product quality and operational risk management. ↩ ↩