Seaports are loud, wet, and full of fuel vapor risk. A wrong phone spec can fail inspection, then fail the first real emergency call.

At a seaport, the right explosion-proof telephone spec depends on berth hazard zoning, salt-fog corrosion, and noise. Most projects combine ATEX/IECEx (Zone 1/2 if required), IP66/IP67 with 316L-grade protection, and SIP integration for PBX, PAGA, and monitoring platforms.

A seaport-ready specification that procurement and safety teams both accept?

A seaport telephone is not just a “device on a wall.” It is part of an emergency chain. It must pass hazardous-area review, survive salt fog, and stay intelligible next to cranes and diesel engines. The best way to avoid rework is to write the spec in a system format: zone + corrosion + audio + integration + installation.

Start from the berth risk, not the product catalog

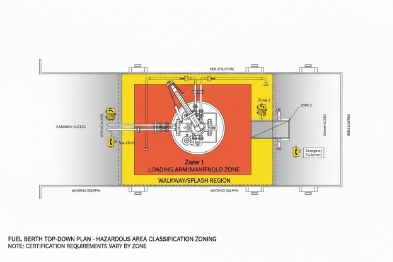

Fuel and chemical berths often have defined hazardous zones around manifolds, loading arms, and vent points. Some areas are clearly non-hazardous. Many ports have mixed zones in one terminal. A single “one model fits all” decision can waste budget or fail compliance. The phone rating should match the exact location.

Treat corrosion as a lifecycle cost

Salt fog and UV are not side issues at the pier. They are the main aging drivers. A strong housing material and fasteners matter. The cable entry matters even more. Water enters at glands and cord ends before it enters through the main body. If the gland and strain relief are weak, IP67 on paper does not help.

Audio is a safety function

In seaport noise, a normal handset can be useless. The audio design must match the real noise profile. That includes mic noise rejection, receiver loudness, and optional accessories like acoustic hoods or an external horn speaker.

Integration makes operations faster

A phone that only calls a number is helpful. A phone that also triggers a beacon, reports health to the network team, and pops the right camera view is far more useful during an incident. SIP integration and simple I/O can turn a wall phone into a true safety endpoint.

| Seaport requirement | What to specify on the phone | What to specify in the project design |

|---|---|---|

| Hazard zone compliance | ATEX 1/IECEx 2 Zone 1/2 if required, correct gas group and T-class | Area classification map and mounting list |

| Salt fog and UV | 316L-level 3 corrosion strategy, marine-grade coating, stainless fasteners | Inspection plan, spare gasket and fastener kit |

| Water and washdown | IP66/IP67 4 handset and cord entry sealing | Gland selection, strain relief, cable routing |

| High noise voice | Noise-cancel mic, high-SPL receiver, hood or headset option | Acoustic placement rules, test call procedure |

| System integration | SIP 5, multicast, relays, ONVIF/RTSP if video is needed | PBX routing, PAGA paging plan, VMS event rules |

A good spec also includes a simple acceptance test: register, hotline call, echo test, beacon trigger, and a visual check for gland sealing. That short list prevents “installed but not usable” outcomes.

Next, the most common question comes first: do ports really need Zone 1 or Zone 2 certified phones at fuel and chemical berths?

Do I need ATEX or IECEx Zone 1 or Zone 2 certification for fuel and chemical berths?

Many ports buy “industrial” phones and hope the berth is safe. Then the safety review arrives, and the project pauses.

Zone 1 or Zone 2 certification is needed only when the berth area is classified as hazardous. Fuel and chemical berths often include Zone 2 areas, and some spots near transfer points can be Zone 1. The phone must match the zone, gas group, and temperature class defined by the site risk study.

How to decide Zone 1 vs Zone 2 for the phone location

The decision should come from the port’s hazardous area classification drawing and operating rules. Still, there is a practical pattern:

- Areas with normal operation release risk near loading connections and vents may push toward Zone 1 in some terminals.

- Areas where explosive atmosphere is not likely in normal operation, or occurs only for short periods, often align with Zone 2.

A phone should not be placed inside a hazardous zone unless the rating is correct. If the phone can be moved a few meters to a non-hazardous location while still being reachable, that can save cost and simplify maintenance. In many projects, a small placement change is the best “engineering value” decision.

Gas group and temperature class matter more than people expect

Ports can handle different products. Gas group and temperature class are not marketing labels. They are safety limits. A conservative approach is to select a higher gas group rating and a stricter temperature class when product mix changes over time. This avoids future rework when the terminal adds a new chemical.

What to write in a tender line

A clean tender line looks like this:

- “Explosion-proof SIP telephone for berth areas, certified to ATEX or IECEx for Zone 2 (and Zone 1 where listed), with suitable gas group and temperature class 6 as per site classification.”

| Item to confirm | Why it matters at berths | What to request from the vendor |

|---|---|---|

| Zone rating | Matches the hazard level at the mounting point | Certificate and marking photo |

| Gas group | Matches product vapor risk | Marking details and limitations |

| Temperature class | Prevents ignition from hot surfaces | Marking plus max surface temp notes |

| Conditions of use | Controls safe installation | Installation instructions and warnings |

When zone compliance is clear, the next major failure point is corrosion and sealing. This is the most common reason seaport phones look old after one year.

What IP66/IP67 rating and 316L anti-corrosion design protect my phones from salt fog and UV at the pier?

Salt fog is relentless. UV exposure is constant. A pier phone must stay sealed and mechanically sound after years of wind and spray.

For exposed pier locations, IP66 is the minimum practical target and IP67 adds extra confidence for temporary immersion or flooding events. A real marine-ready design also needs corrosion-resistant housings, stainless hardware, stable gaskets, and protected cable entries, not only an IP label.

IP rating: what to demand for the whole assembly

A common mistake is to check the main enclosure IP rating and ignore the handset and cord entry. At a pier, water often enters at the cord and gland, not through the metal body. A useful procurement rule is:

- “IP66/IP67 for the full phone assembly, including handset, cord entry, and cable gland interface.”

If the phone uses a coiled cord, the end boots and strain relief must also be resistant to salt and UV. If the phone uses an armored umbilical, the armor termination must be sealed and bonded correctly.

Material strategy: 316L is strong, but details decide lifetime

316L stainless housings are popular because they resist many corrosion modes better than basic metals. Still, offshore-style lessons apply at seaports too:

- Screws, hooks, and brackets must also be corrosion resistant.

- Mixed metals can create galvanic corrosion if not controlled.

- Coatings must protect edges and holes, not only flat surfaces.

Seals and gaskets: pick materials that stay elastic

Gaskets fail from compression set, oil exposure, and UV aging. A seal that looks fine can lose elasticity and leak after thermal cycling. A safer approach is to ask for gasket material details and a maintenance interval recommendation. It is normal to treat gaskets as planned replacement parts in marine environments.

| Corrosion and sealing point | Typical pier failure | Design choice that reduces it | Simple field check |

|---|---|---|---|

| Fasteners and hooks | Rust, loose hardware | Stainless hardware set | Visual and torque check |

| Handset cord entry | Water ingress at boot | Strong strain relief + sealing | Pull test + spray check |

| Door gasket | Compression set leaks | Stable gasket material | Visual and leak signs |

| Surface finish | Pitting and staining | Marine-grade coating or 316L | Inspection after washdown |

Once the phone survives salt and water, the next question becomes human: can crews actually hear and be heard next to cranes and engines?

How can I guarantee intelligible calls over cranes and diesel noise—handset, headset, or horn speaker up to 110 dB?

Seaport noise is not steady. It spikes with engines, cranes, and alarms. Intelligibility must be designed, not assumed.

Clear calls near cranes and diesel noise usually need a noise-cancelling microphone, a high-SPL receiver, and an acoustic hood or headset option. For very loud areas, a horn speaker or external PA path can support alerts up to about 110 dB, but the workflow must stay simple and safe for hearing.

Choose the right user interface for the noise zone

A handset is familiar and fast. It works well when the receiver is loud and the mic rejects background noise. Still, in extreme noise zones, a handset can struggle because the user cannot hear the far end clearly.

A headset option can improve intelligibility because it seals closer to the ear and keeps the mic closer to the mouth. This is useful for crane operators and berth crews who already wear PPE. The headset must be rugged and easy to replace.

A horn speaker is not a “call tool” in the normal sense. It is an alert tool. It can be used to broadcast a warning or to signal that help is needed. A horn solution should be paired with clear rules so it does not create confusion during normal operations.

Audio specs that matter more than marketing words

For high noise, it helps to request measurable items:

- Microphone type and noise rejection behavior

- Receiver output level and distortion control

- Sidetone control so users do not over-shout

- Optional acoustic hood for windy or noisy spots

Test intelligibility the same way the port will use it

A pier acceptance test should be done during real operations, not in quiet hours. A short test plan works:

- Place a hotline call from each berth phone

- Confirm far-end understands normal speech without shouting

- Confirm user can understand far-end instructions

- Confirm beacon or indicator works during the call if required

| Noise condition | Best handset approach | When to add accessories | What to test |

|---|---|---|---|

| Moderate pier noise | Noise-cancel mic + loud receiver | Optional hood | Two-way clarity |

| Crane and engine peaks | High-SPL receiver + hood | Headset for regular use | Speech clarity without shouting |

| Extreme zones | Headset primary | Horn for alert, not conversation | Workflow clarity and safety |

After audio, the last key requirement is integration. Ports rarely want standalone phones. They want SIP plus paging, alarms, and video linkage.

Will my SIP explosion-proof phones integrate with IP PBX, PAGA, and VMS via PoE, dual LAN, and ONVIF/RTSP?

Integration is where ports save time. The control room needs fast location awareness and quick escalation. A phone should fit the existing network and security tools.

Yes. SIP explosion-proof phones can integrate with IP PBX for calling, with PAGA using multicast paging or gateways, and with VMS using ONVIF/RTSP when video is included. PoE simplifies power, dual LAN can support redundancy or daisy-chain designs, and relay I/O can trigger beacons and alarms.

IP PBX integration: keep emergency workflows short

A port should define a few standard call flows:

- Hotline to port control

- Group ring to safety team

- Auto-dial from a button or dry contact input

- Clear location naming for each endpoint

These flows should not rely on complex menus. In an incident, speed matters more than features.

PAGA integration: multicast and relays are practical tools

PAGA can be connected through:

- Multicast paging 7 groups for one-to-many announcements

- SIP paging gateways that inject audio into amplifier networks

- Relay outputs that trigger strobe beacons or local alarms when a call starts

A small detail matters: QoS. Paging traffic and RTP traffic should be prioritized so crane camera traffic does not steal voice packets on uplinks.

VMS integration: only add video when it adds real value

If the port wants situational awareness, a phone with a camera can support RTSP streams and ONVIF 8 discovery in many setups. The best practice is to trigger camera pop-up on a call event. This reduces operator clicks and speeds response.

PoE and dual LAN: design for long runs and cabinet realities

PoE 9 simplifies installation, but the PoE budget must include peak load and cable distance. Dual LAN can be used for redundancy or for controlled pass-through designs, depending on the site network rules. Some ports prefer a strict star topology. Others allow local chaining with industrial switches. The right answer depends on maintenance access and cybersecurity policy.

| Integration need | Feature to request | Why it helps at a seaport | One design rule |

|---|---|---|---|

| Emergency calling | SIP PBX + hotline | Fast contact to control room | Short dial plan |

| Mass alerts | Multicast or paging gateway | Fast PA/GA support | Use QoS 10 and VLAN separation |

| Visual confirmation | ONVIF/RTSP video option | Faster situational awareness | Pop-up on call event |

| Local alarms | Relay outputs + beacon | Makes help point visible | Latch and acknowledge rules |

| Power simplicity | PoE with margin | Less wiring and faster install | Monitor PoE and link state |

When integration is planned, the system becomes easier to operate and easier to maintain. It also becomes easier to prove during acceptance tests.

Conclusion

Seaport Ex phones work when zone rating matches the berth, corrosion and sealing are marine-ready, audio fits real noise, and SIP integration supports PBX, paging, and video workflows.

Footnotes

-

ATEX EU directives regulating equipment and protective systems intended for use in potentially explosive atmospheres. ↩

-

IECEx International certification system for equipment used in explosive atmospheres, facilitating global trade. ↩

-

316L-level Referring to 316L stainless steel, a low-carbon alloy offering superior resistance to corrosion, especially in marine environments. ↩

-

IP66/IP67 Ingress Protection ratings defining resistance to dust (first digit 6) and water jets (6) or temporary immersion (7). ↩

-

SIP Session Initiation Protocol; a signaling protocol used for initiating, maintaining, modifying and terminating real-time sessions. ↩

-

temperature class A classification system (T1 to T6) that limits the maximum surface temperature of equipment to prevent ignition of flammable gases. ↩

-

Multicast paging A network efficiency method where a single audio stream is sent to a group of IP devices simultaneously. ↩

-

ONVIF An open industry forum for the development of a global standard for the interface of physical IP-based security products. ↩

-

PoE Power over Ethernet; technology that passes electric power along with data on twisted pair Ethernet cabling. ↩

-

QoS Quality of Service; the use of mechanisms or technologies to manage traffic and ensure the performance of critical applications like voice. ↩