Outdoor phones can sit in public areas for years. If the housing plastic burns or drips, a small incident can turn into a big safety and liability issue.

Most outdoor telecom and industrial buyers specify UL 94 V-0 for plastic housings, then verify the exact resin grade, thickness rating, and UL file. If the housing is metal, focus UL 94 on internal plastics and the keypad/handset parts.

A practical fire-safety spec for outdoor housings

Flame class is not “one rule for all.” The required UL 94 level depends on where the telephone is installed, what local codes apply, and what the operator spec demands. In most B2B tenders, the buyer does not want a debate. They want a clean line in the datasheet and proof that the material matches the BOM and stays consistent over time.

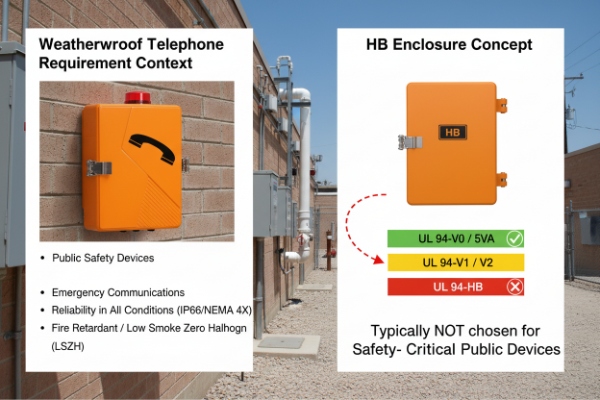

In outdoor deployments, the safest default for a plastic housing is UL 94 V-0 at the minimum wall thickness used in the molded part. V-0 is widely accepted because it self-extinguishes quickly (within 10 seconds) and reduces flaming drip risk. UL 94 V-2 1 can be accepted for less critical internal brackets, but it allows flaming drips, so it is harder to defend in public-facing or industrial sites. HB is usually seen as a low bar for outdoor enclosures, unless the part is non-structural, protected, and not near ignition sources.

UL 94 5VA 2 is another step up, but it can force thicker walls, different resin systems, higher cost, and sometimes lower impact strength. It can be right for high-risk equipment zones or customer specs that demand it, but it should be chosen by hazard level, not by habit.

Also, UL 94 is a material flammability test. It is not the full product safety certification. Many customers still ask for it because it is a simple filter that blocks weak materials early.

The rule that many buyers miss: UL 94 is thickness-specific

A resin can be V-0 at 1.5 mm and only V-2 at 0.8 mm. If a housing has thin ribs, snap features, or a cosmetic faceplate that is thinner than the nominal wall, the rating must match the thinnest area that matters.

…What to specify in a purchase document

Write requirements that are easy to audit. Avoid loose phrases like “flame retardant” without a level, thickness, and file reference.

| Item to specify | Best practice for outdoor phones | What to request from the supplier |

|---|---|---|

| Housing resin UL 94 class | V-0 preferred, at actual min thickness | UL file or Yellow Card 3, thickness noted |

| Internal plastics UL 94 class | V-0 or V-2 based on risk | BOM mapping of each plastic part to resin grade |

| Metal housing case | UL 94 for keypad/handset/internal plastics only | List of plastic parts + their ratings |

| Proof documents | Third-party listing + COA/COC + traceability | Lot numbers tied to resin batches |

A clear flame spec reduces bid confusion and speeds up compliance checks on real production lots.

Which UL94 rating suits outdoor enclosures—HB, V-2, V-0, or 5VA?

If a tender only says “UL 94,” suppliers can ship very different materials. That can create quality drift and compliance risk across regions.

For most outdoor weatherproof telephone housings made of plastic, UL 94 V-0 is the most common and easiest to defend. Use V-2 only for low-risk internal parts. Use HB only when the part is non-critical and shielded. Use 5VA when the customer spec or hazard level clearly demands it.

HB is a horizontal burn rating. It is often used for consumer or low-risk parts. In outdoor public safety and industrial phones, HB usually feels weak because the housing is exposed to the environment, vandal risk, and unknown misuse. A buyer may still accept HB for parts that are not near wiring or heat sources, but it should be a conscious choice with a reason written down.

V-2 and V-0 are vertical burn ratings. V-0 is the common target because it reduces burn time and reduces dripping risk. V-2 can allow flaming drips, so it may fail a customer’s internal safety review even if it passes the test. That does not mean V-2 is “bad.” It can be fine for internal clips, spacers, and small brackets, where ignition exposure is low and dripping is not relevant. But for the main housing, V-0 is the safer baseline.

5VA is more demanding. It can be requested for enclosures where a higher flame resistance margin is needed. In practice, it can also push the design to thicker sections and different resin families. Some 5VA materials can be more brittle, so impact performance and IK targets need checking. For outdoor phones that must survive hits and tools, a higher flame class that hurts impact strength can create a different failure mode.

The clean approach is to match the UL 94 class 4 to the hazard and the part function:

- …Housing shell: aim for V-0 at the minimum wall thickness.

- Faceplate and keypad bezel: V-0 if exposed and structural.

- Internal brackets: V-0 or V-2 depending on proximity to wiring and heat.

- Gaskets: UL 94 is not always meaningful for elastomers, so focus on material safety data and customer requirements.

| UL 94 class | Where it fits on outdoor phones | Why buyers choose it | Common pitfalls |

|---|---|---|---|

| HB | Low-risk internal parts only | Cost and wide availability | Too weak for housing, vague specs |

| V-2 | Internal parts with low ignition exposure | Better than HB, lower cost than V-0 | Flaming drips can be unacceptable |

| V-0 | Main housing and exposed plastic parts | Strong default for tenders | Must match the real part thickness |

| 5VA | High-risk projects or strict operator specs | Extra margin in flame behavior | Cost, thicker walls, possible impact trade-offs |

For most buyers, the best answer is simple: UL 94 V-0 for the housing, unless a stronger class is required by the operator or code.

Do GRP or PC-ABS parts carry valid UL files for this model?

A housing can claim V-0, but the real question is: “Is that exact resin grade listed, and is it the one inside the BOM today?” That is where many projects break.

GRP and PC-ABS can be UL 94 V-0, but it must be backed by valid UL files for the exact resin grade, color system, and thickness used. The supplier should provide the UL file reference and show a BOM-to-material mapping for this model.

GRP (glass reinforced plastic) 5 is a broad term. It can mean different base resins and filler systems. Some GRP compounds are thermoset and can perform well in flame tests. Others are not designed for flame performance. So the buyer should not accept “GRP is fireproof” as a statement. The only useful proof is a material listing tied to a compound name and supplier.

PC-ABS is also broad. Many PC-ABS grades exist, including FR grades that can achieve V-0 at certain thicknesses. But there is a trap: the rating is linked to thickness, and sometimes to color. Dark colors can change burn behavior because of pigment chemistry. If the supplier changed masterbatch or used regrind without control, performance can drift.

For this model, a clean compliance package should include:

- The resin manufacturer name and exact grade code for each part

- …The UL file or listing reference that covers UL 94 rating

- The rated thickness and the minimum thickness of the molded part

- …A statement about allowed regrind percentage, if any

- A change control rule for resin or color changes

If the housing is metal, the same approach applies to internal plastics. It is common to use metal housings in heavy-duty telephones. In that case, UL 94 on the housing is not the issue. The issue becomes keypad parts, handset plastics, cord strain relief, speaker holders, and connector bodies.

Is flame performance verified after UV and salt-fog aging?

Outdoor phones age in sunlight, heat, moisture, and salt in many regions. …Materials can change with time. Coatings can crack. Plasticizers can move. It is reasonable to ask if the flame rating still holds after aging.

UL 94 ratings are typically based on material condition as tested, so extra verification after UV and salt-fog is a smart project-level requirement. For outdoor programs, verify flame performance on aged samples when the operator spec is strict or when the material is close to the margin.

UV exposure can cause surface oxidation 6 and micro-cracking on some polymers. Salt-fog mainly attacks metals and coatings, but it also adds moisture and contamination stress. These factors can change how a part ignites and how it drips. It does not always make things worse, but it can. It also exposes weak process control, such as poor molding, voids, contamination, or incorrect resin mixing.

A practical way to handle this is to treat “post-aging flame check” as a qualification test, not a routine test on every lot. Run it:

- When selecting a new resin grade

- When changing color, masterbatch, or coating

- When changing supplier

- When the housing wall thickness changes

- When the phone targets harsh solar and coastal sites

The test method can be aligned with the project’s UV and corrosion plan using standards like ISO 4892-2 7 for weathering, ASTM G154 [^8] for fluorescent UV, or ASTM B117 8 for salt fog. Many teams already run UV exposure for color stability and salt-fog for coating and fasteners. Add a flame check on those aged coupons or molded parts. The goal is not to rewrite UL. The goal is to prove that the chosen resin and process remain stable under real outdoor stress.

Also, aging should be realistic. Test molded samples with real thickness and surface texture. Flat plaques can hide molding defects and do not represent ribs and corners.

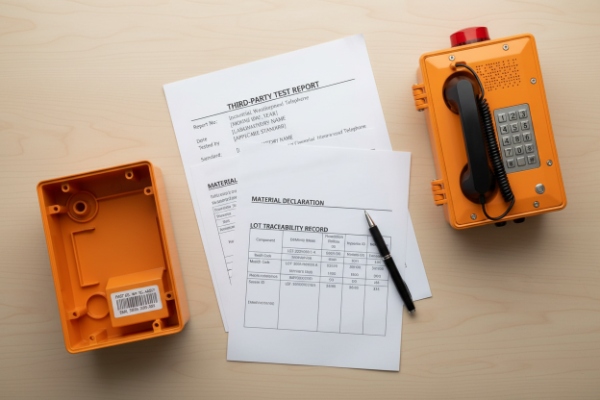

Are third-party certificates and lot traceability provided?

A flame class on a datasheet is not enough. Operators and integrators often want proof that each shipment matches the approved material. That means third-party documents and traceability down to lots.

Yes, serious outdoor projects should include third-party listings, certificates of conformity, and lot traceability that ties each housing batch to resin lots, color batches, and process records. This is the only practical way to keep UL 94 claims stable over years.

Third-party evidence usually comes in two layers:

- The material listing that shows the resin grade and its UL 94 rating at thickness.

- …The production documents that prove the shipped parts used that listed material.

For traceability 9, the most useful setup is simple:

- Each molded housing lot has a lot number on the carton and on the inspection report.

- That lot number links to the resin lot number, masterbatch lot, and molding machine record.

- Incoming resin has a COA that confirms grade and key properties.

- The outgoing product has a COC that states the housing resin and rating, and references the approved UL file.

This approach also protects the supplier. If a complaint appears in year three, the supplier can check if the issue is aging, misuse, or a one-time material deviation.

| Document / control | What it proves | What to include in your RFQ |

|---|---|---|

| UL material file reference | Resin grade is listed for UL 94 at thickness | Provide file reference and rated thickness |

| COA for resin and masterbatch | Correct material delivered to factory | Lot numbers and grade codes |

| COC for shipment | Shipped housings match the approved BOM | Housing resin grade + UL 94 class stated |

| Lot traceability record | Link between parts and material lots | Lot mapping template and retention time |

| Change control notice | No silent resin/color changes | Approval needed before changes |

When the supplier provides these items up front, the project moves faster and the buyer’s compliance team has fewer questions.

Conclusion

For outdoor weatherproof telephone housings, UL 94 V-0 is the safest default for plastics. Then lock resin grades, thickness, UL files, post-aging checks, and lot traceability to keep results stable.

…Footnotes

-

Detailed overview of UL 94 Vertical Burn tests (V-0, V-1, V-2) and the criteria for pass/fail regarding burning time and flaming drips. ↩

-

Explanation of the strict UL 94 5VA/5VB surface burn tests used for high-risk enclosure applications. ↩

-

The UL "Yellow Card" program verifies that a specific plastic resin has met safety and performance standards, including flammability. ↩

-

A practical breakdown of what UL 94 flammability ratings mean for cable components and enclosures. ↩

-

Discusses the fire-resistant properties of Glass Reinforced Plastic (GRP) and its applications in safety-critical sectors. ↩

-

Technical article analyzing how heat and UV exposure can degrade the flame-retardant properties of PC/ABS over time. ↩

-

Describes ISO 4892-2, the standard for accelerated weathering of plastics using Xenon-arc lamps to simulate sunlight.[^8]: Covers ASTM G154, the standard practice for operating fluorescent UV lamp apparatus for exposure of nonmetallic materials. ↩

-

Details the ASTM B117 salt spray test used to evaluate the corrosion resistance of coated materials in marine environments. ↩

-

Explains the UL Fabricated Parts Traceability Program, ensuring that molded parts are made from the specified UL-recognized materials. ↩