A front panel can look rugged and still fail after one hit. When it bends, the gasket line opens. Then IP66 becomes a service call.

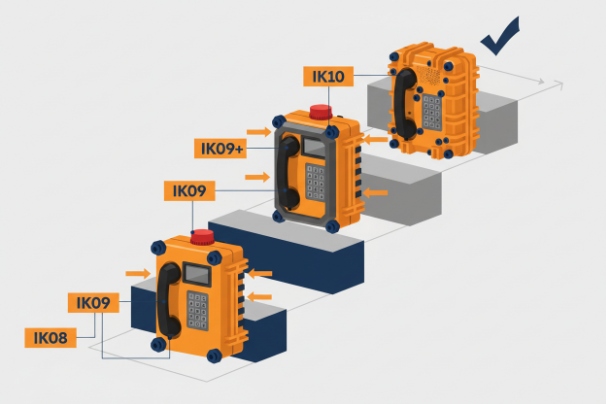

In practice, most standard weatherproof telephones target IK08 on the front panel, while vandal-risk models target IK10. The real result depends on the certified scope, test mounting, and whether the window and keypad zones are included.

Impact rating is a package, not a sticker

An IK number is only useful when it is tied to three things: the tested assembly, the impact points, and the mounting method. A front panel can pass a lab strike on a rigid wall, yet fail on site when it is installed on thin cladding. A panel can also pass on the flat area, yet crack at the window bezel or keypad corner because those zones were not part of the certified scope.

In most outdoor and industrial programs, the “front panel” is not just a flat plate. It is a stack: plate, window frame, keypad frame, speaker grill, inner reinforcement, and the screws that clamp everything to the back box. The weakest layer sets the real IK performance. That is why some suppliers advertise IK10, but the rating only applies to the metal back box, not the full front assembly that the public can hit.

A practical way to think about IK levels:

-

IK08 is for rough handling and accidental knocks.

-

IK09 is for heavier knocks and some misuse risk.

-

IK10 is for real vandal risk, like kicking, ramming, or striking with a heavy object.

Front panel strength must also protect the seal. If the panel dents or bows, the gasket compression changes. Many field failures happen even when the panel is “not broken.” The phone still works, but water and dust start to enter over time.

What to request before accepting an IK claim

Ask for a test report that names the IK level, lists impact points, and shows the mounting condition. Also ask if the window and keypad were installed during testing. If the supplier cannot show this, the claim is hard to trust.

| IK level | Impact energy | What it means on site | Typical front-panel target |

|---|---|---|---|

| IK08 | 5 J | Hard knocks, tool hits, accidental impact | Standard outdoor phones |

| IK09 | 10 J | Heavy knocks, higher misuse risk | Semi-public areas |

| IK10 | 20 J | Vandal risk, deliberate abuse | Public-facing and remote sites |

A clear IK story makes procurement easier, and it reduces surprise failures after deployment.

Keep reading, because the next sections show how to confirm the rating, how the IEC/EN test is done, and what materials and thickness usually deliver the result.

Which IK impact rating is certified for the front panel—IK08, IK09, or IK10?

A tender can say “IK10,” yet the phone arrives with an IK08 face and an IK10 back box. That mismatch creates cost, delay, and conflict at site acceptance.

For most controlled industrial sites, an IK08 front panel is a practical baseline. For exposed public areas, transport, or remote outdoor emergency points, an IK10 front panel is the safer target. IK09 sits in the middle and only helps when the certified scope is clear.

Match the rating to the abuse profile

The best rating is the one that matches the real risk. A refinery walkway phone may only see accidental tool hits and occasional bumps. IK08 is often enough there, as long as the seal stays intact. A highway call point, campus emergency phone, or public corridor telephone will see intentional hits. In those areas, IK10 is a better match.

Many buyers choose IK10 for peace of mind. That is reasonable, but it only works when the full front assembly is designed and tested to IK10. If the window, keypad, or speaker grill is weaker, the unit will still fail in real abuse.

Confirm the “front panel” definition

Some reports define the “enclosure” as the complete housing. Others define it as a back box only. The words matter. A safe spec line is “Front assembly IK10 including faceplate, window/lens, keypad area, and grill, tested when mounted per installation instructions.”

Typical market positioning

In DJSlink-style programs, the common pattern is:

-

Standard weatherproof telephone: IK08 1 front panel, strong seal, good for industrial and campus installs.

-

Vandal-resistant heavy-duty: IK10 2 front panel, reinforced door, stronger hinge and latch, built for public exposure.

| Installation zone | Likely abuse level | Recommended front panel IK | Notes |

|---|---|---|---|

| Controlled industrial plant | Medium | IK08 | Focus on seal and maintenance |

| Factory floor near forklifts | Medium to high | IK08–IK09 | Add guard if impact is frequent |

| Public building corridor | High | IK10 | Include keypad/window in scope |

| Roadside / remote emergency | High | IK10 | Mounting and substrate are critical |

| Coastal public area | High + corrosion | IK10 | Use 316 hardware and rigid mounting |

When the scope and site risk are aligned, the IK rating becomes a real protection tool instead of a marketing label.

What joule energy and hammer type were used per IEC/EN 62262?

An IK label without test details is incomplete. Two phones can both claim IK10, yet one was tested with the full front assembly and the other was tested on a simplified shell.

IEC/EN 62262 links IK codes to impact energy in joules, and it defines the test setup, the number of impacts, and the hammer apparatus type. For IK08/IK09/IK10, impacts are typically produced using a pendulum or vertical hammer setup with standardized striking elements.

Energy levels that matter for front panels

For weatherproof telephone front panels, the key energies are:

-

IK08 = 5 J

-

IK09 = 10 J

-

IK10 = 20 J

This is why IK10 feels like a different class. It is not a small step. It is a big jump in panel bending risk and in latch and hinge stress.

Hammer types in simple terms

IEC 62262 3 references impact methods that are aligned with hammer testing practices. In the test world, three common apparatus types are used across the IK range:

-

Spring hammer (more common at lower energies)

-

Pendulum hammer (commonly used for higher energies)

-

Vertical hammer (drop hammer / free-fall style)

For IK08 to IK10, pendulum and vertical methods are common because the energies are higher. The striking element shape is standardized in the hammer apparatus so results are repeatable. Many front panel failures come from concentrated strikes near edges and cutouts, so the striking element shape and position matter.

Impacts, distribution, and what “pass” should mean

A practical IK report should state how many impacts were applied and where. Many labs distribute impacts across exposed surfaces and limit repeated hits at the exact same point. For front panels, a strong project spec also adds functional checks after test:

-

Door still closes and latches.

-

Gasket compression line is not damaged.

-

No sharp edges are created.

-

Keypad still operates.

-

Audio is not blocked by a deformed grill.

| IK code | Energy | Typical apparatus used | What to verify in the report |

|---|---|---|---|

| IK08 | 5 J | Pendulum impact test 4 or vertical hammer | Impact points include edges and cutouts |

| IK09 | 10 J | Pendulum or vertical hammer | Window and keypad installed during test |

| IK10 | 20 J | Pendulum or vertical hammer | Mounting per instructions, no panel bowing |

When a supplier shares the exact hammer type and impact points, it becomes much easier to compare vendors fairly.

Does the panel resist repeated strikes on edges, window, and keypad zones?

A panel can survive one clean strike on the flat area and still fail after repeated hits on edges and features. Real vandal behavior targets corners, windows, keypads, and speaker grills.

A strong front panel design must handle repeated impacts in weak zones, not only a single hit on the center. The best proof is a test report that shows impacts on edges, window frame, keypad perimeter, and grill area, followed by functional and sealing checks.

Why edges and cutouts fail first

Edges are stiffer but also more brittle in many assemblies. Stress concentrates at corners, screw holes, and cutouts. A window opening reduces section strength. A keypad recess creates thin walls and sharp transitions. When a heavy hit lands near these features, cracks can start or the panel can crease. Even a small crease can reduce gasket pressure nearby.

Windows and keypads need their own protection plan

If a window is required, it must be held by a strong bezel that spreads load. A window that relies only on adhesive or thin tabs is risky at higher IK levels. For keypads, the perimeter seal and the backing plate are key. A keypad mat can survive impact if the backing support prevents the mat from being punched inward.

Repeated impacts and “still usable”

Passing IK is not only “no hole.” In the field, a phone must remain usable. That means the keypad must still click, the handset cradle must still align, and the speaker grill must not deform into the acoustic path. Some guards help impact, but they can also block audio. The design needs enough open area and a short acoustic path so speech stays clear.

| Zone | Common failure after repeated hits | Design feature that helps | What to test |

|---|---|---|---|

| Panel edges | Crease, corner crack | Edge radius, thicker return flange | Impacts on corners and edges |

| Window area | Crack, pop-out, bezel deformation | Metal bezel + thick lens + support ring | Impacts near window perimeter |

| Keypad zone | Mat punch-in, seal tear | Backing plate + perimeter clamp | Impacts around keypad corners |

| Speaker grill | Dent blocks sound, rattles | Reinforced grill ribs + standoff cavity | Impacts on grill + audio check |

| Screw bosses | Pull-out, loosening | Metal inserts, larger washers | Post-test torque and closure check |

If the report does not show impacts in these weak zones, the rating is less meaningful for public-facing deployments.

What material and thickness deliver the rating—316L, GRP, or reinforced aluminum?

Material selection changes the whole front panel story. It affects stiffness, dent resistance, corrosion, and weight. It also affects how the phone feels after impacts and after years of weather.

316L stainless is the common choice for heavy-duty vandal resistance and coastal corrosion. Reinforced aluminum can reach high IK with smart ribs and backing plates while keeping weight lower. GRP can perform well when thick and ribbed, but windows and inserts need careful design.

316L stainless front panels

316L stainless steel 5 handles corrosion well in coastal and salt-fog sites, and it keeps strength after years outside. It also resists cutting and prying better than many options. For IK targets, stainless often relies on thickness plus formed edges and reinforcement. A flat thin stainless plate can still dent. A formed plate with return flanges and strong mounting points performs much better.

Reinforced aluminum front panels

Aluminum can achieve IK08 to IK10 when designed correctly. The key is section design, not only thickness. Ribs, backing plates, and formed edges spread impact load. Aluminum also helps with thermal spreading 6, which can protect electronics in full sun. The main risk is galvanic corrosion at stainless fasteners if joints are not isolated and sealed.

GRP front panels

Glass reinforced plastic (GRP) 7 is strong for its weight and can handle impacts when designed with thickness and ribs. It does not corrode like metal, but inserts and fasteners still need corrosion planning. GRP can crack if sharp corners are used or if fiber orientation and molding quality are poor. For high IK targets, the window and keypad framing must be very strong, because cutouts weaken the panel.

Typical thickness ranges (practical guidance, not a promise)

Actual thickness depends on geometry, reinforcement, and mounting. Still, these ranges are commonly seen in rugged outdoor designs:

| Material | IK08 practical build | IK10 practical build | Notes |

|---|---|---|---|

| 316L stainless | ~1.5–2.0 mm with formed edges | ~2.0–3.0 mm with reinforcement | Best for vandal + coastal |

| Reinforced aluminum | ~2.0–3.0 mm with ribs | ~3.0–4.0 mm with ribs/backing plate | Lower weight, needs galvanic control |

| GRP (ribbed) | ~3.5–5.0 mm with ribs | ~5.0–7.0 mm with ribs + strong inserts | Cutouts need extra support |

Do thicker panels or guards affect audio usability?

Yes, they can. A thicker grill with small holes reduces open area. That reduces volume and clarity, especially at higher frequencies. A deep guard can create echo and muffled sound. The fix is to keep enough total open area and to shape the acoustic cavity so voice stays clear. A good IK10 design protects the grill with ribs and geometry, not by choking the holes.

| Protection choice | Impact benefit | Audio risk | Better approach |

|---|---|---|---|

| Thick plate + tiny perforations | High | Muffled voice | Reinforced ribs + larger open area |

| Deep recessed grill | Medium | Echo and loss of clarity | Shallow recess + tuned baffle |

| External cage tight to grill | High | Blocks sound, rattles | Stand-off guard + membrane |

| No reinforcement, only thickness | Medium | None | Add backing plate and edge flanges |

Material and thickness selection should always be paired with mounting design. A strong plate on a weak wall will still fail under IK10 energy.

Conclusion

IK08 fits controlled outdoor sites. IK10 fits real vandal risk. Confirm the test scope, impact testing methods 8, and mounting. Then choose 316L, reinforced aluminum, or ribbed GRP with proven edge and polycarbonate window 9 protection.

Footnotes

-

Explains the IK08 impact protection rating, which corresponds to withstanding 5 joules of impact energy. ↩

-

Details the IK10 rating requirements, representing protection against 20 joules of impact energy, suitable for high-vandalism areas. ↩

-

Reference to the IEC 62262 standard that defines the degrees of protection provided by enclosures against external mechanical impacts (IK code). ↩

-

Describes the pendulum impact test method used to verify impact resistance according to international standards. ↩

-

Overview of 316L stainless steel properties, highlighting its superior corrosion resistance and suitability for marine environments. ↩

-

Explains how thermal spreaders work to dissipate heat in electronic enclosures, which is beneficial for aluminum panels. ↩

-

Discusses the properties and applications of Glass Reinforced Plastic (GRP), noting its high strength-to-weight ratio. ↩

-

A technical guide to various impact testing methods, including Charpy and Izod, to understand material toughness. ↩

-

Information on polycarbonate sheet materials used for impact-resistant windows in rugged enclosures. ↩