Rain, dust, and wash-down can destroy a “certified” phone fast. That failure often shows up during an emergency, not during a quiet test.

Most explosion-proof telephones ship with IP66 as a baseline, with many models offering IP67 for temporary immersion. Higher ratings like IP68 or IP69K are possible, but they should be specified only when the site exposure truly demands them.

IP rating for Ex phones is a system promise, not only an enclosure label

Why IP matters even when Ex is correct

ATEX and IECEx 1 focus on explosion safety. IP rating 2 focuses on water and dust ingress. In real plants, ingress is the first reason phones fail. Water enters through a gland. Dust builds up inside a hook switch. Corrosion starts at a screw head. Then the phone becomes unreliable. A reliable Ex phone must be both Ex-correct and sealed for the site exposure.

What IP digits really tell you

IP has two digits:

-

The first digit is for solids and dust.

-

The second digit is for water.

For example:

-

IP66 means dust-tight and protected against powerful water jets.

-

IP67 adds temporary immersion protection 3.

-

IP68 means continuous immersion, but depth and time are defined by the manufacturer.

-

IP69K targets high-pressure, high-temperature washdown, and it is often tied to specific wash test setups.

Typical IP levels seen in explosion-proof telephones

In industrial Ex telephone projects, these are common:

-

IP66: outdoor process units, tank farms, offshore modules with routine wash-down.

-

IP67: areas with drainage issues, temporary flooding risk, or heavy spray where immersion can happen.

-

IP68: pits, sumps, or locations where the device can be submerged beyond “temporary.”

-

IP69K: food, pharma, or special wash bays with high-pressure hot-water cleaning.

A quick personal placeholder fits here. During one offshore retrofit, the phone body was strong, but the wrong gland insert was used. The phone failed after repeated hose-down. The fix was simple, but the downtime was not.

The most important rule

The phone does not “have” an IP rating by itself. The installed assembly has it. Cable, gland, stopping plug, and installation torque decide whether IP66 stays IP66.

| IP rating | Dust protection | Water protection | Typical Ex phone use |

|---|---|---|---|

| IP66 | Dust-tight | Powerful water jets | Most outdoor hazardous sites |

| IP67 | Dust-tight | Temporary immersion | Areas with flood or pooling risk |

| IP68 | Dust-tight | Continuous immersion (defined by maker) | Sumps, pits, special marine splash/submersion risk |

| IP69K | Dust-tight | High-pressure, hot wash | Hygiene washdown zones |

A good spec keeps IP realistic. It also forces the installer to preserve it at the entries.

Now the next sections answer the four questions that usually appear in tenders and FAT discussions.

The best results come when IP is chosen based on real exposure, not on fear.

Is IP66 or IP67 sufficient for hazardous outdoor sites with rain, dust, and hose-down cleaning?

Outdoor hazardous sites are harsh, but not every site needs immersion protection. Over-specifying creates cost and makes maintenance harder.

IP66 is usually sufficient for rain, dust, and hose-down cleaning in outdoor hazardous areas, while IP67 is a better choice when temporary flooding or water pooling can reach the phone enclosure or cable entry.

When IP66 is the right baseline

IP66 fits most real-world outdoor Ex phone locations:

-

refinery process units 4 with periodic hose-down

-

tank farms with wind-driven rain and dust

-

offshore modules with spray and wash-down routines

-

pipeline block valve stations with dust and storms

IP66 is strong because it targets two common threats: dust and water jets. In many plants, “hose-down” is not submersion. It is jets. So IP66 is a practical baseline that balances protection and serviceability.

When IP67 should be specified

IP67 becomes important when water can sit and rise:

-

low-mounted phones near drains that clog

-

bunded tank farm areas after storms

-

tunnels and underpasses with condensation and pooling

-

marine decks where wash water can collect behind structures

If the phone can be partially submerged, IP67 reduces risk. Still, IP67 is not a free pass. The gland and cable jacket must also tolerate immersion conditions. A poor gland can leak long before the enclosure does.

Watch the real weak point: the entry and the junction

Most water problems happen at:

-

cable gland compression seal

-

unused entry stopping plug

-

junction box covers and gaskets

-

cable jacket damage from UV or chemicals

That is why a good spec always combines IP with entry hardware requirements.

| Outdoor condition | Practical IP target | Why |

|---|---|---|

| Rain + wind + dust | IP66 | Jet resistance plus dust-tight |

| Hose-down cleaning | IP66 | Designed for powerful water jets |

| Periodic pooling near base | IP67 | Adds temporary immersion margin |

| Frequent flooding events | IP67 or IP68 | IP67 may not be enough if water stays high |

A simple site rule

If the phone is mounted above the highest expected standing water level and the site uses hose-down, IP66 is usually enough. If the phone is low, near drains, or in flood-prone areas, IP67 is safer.

The next question is about higher ratings. IP68 and IP69K should not be automatic. They should be tied to a clear exposure story.

When should IP68 or IP69K be specified for submersion or high-pressure washdown applications?

Many buyers ask for “the highest IP” to be safe. That often backfires because the design can become more complex and harder to service.

Specify IP68 only when continuous or deeper submersion is realistic, and specify IP69K only when the site uses high-pressure, high-temperature washdown that can defeat standard IP66 designs at seams and cable entries.

IP68: only for real submersion risk

IP68 is not one fixed test. It means immersion beyond IP67, but the depth and time are defined by the manufacturer. That is why IP68 must be written with numbers:

-

required depth (meters)

-

required duration (hours or days)

-

water type (fresh water, seawater, chemical mix)

-

pressure cycling expectations, if any

IP68 is appropriate for:

-

phones mounted in pits or low points where flooding can last

-

marine or coastal sites where wave splash can act like intermittent submersion

-

special process areas where wash water can cover equipment for long periods

Still, in many hazardous sites, submersion is not normal. If submersion is not realistic, IP68 is a cost with little benefit.

IP69K: for high-pressure hot wash

IP69K is mainly for harsh washdown regimes. Think high-pressure jets at close distance, often with hot water. This is common in hygiene-driven industries and special wash bays. It is not common in most refineries. Some chemical plants do have aggressive wash routines, but they often use solvents and lower pressure. The wash method matters.

IP69K can be useful when:

-

cleaning uses high-pressure lances very close to the device

-

water is hot and can soften seals over time

-

cleaning hits the device from many angles, including upward spray

Specify the whole “wash profile,” not only IP69K

A smart tender states:

-

maximum nozzle pressure and distance

-

water temperature

-

cleaning chemical exposure

-

frequency of cleaning

This avoids a mismatch where the phone passes a lab test but fails under real cleaning behavior. This is common in high-pressure washdown applications 5 and special wash bays.

| Use case | Better rating | What to add in the spec |

|---|---|---|

| Temporary flooding | IP67 | mounting height and drainage assumptions |

| Frequent long submersion | IP68 | depth and time numbers |

| High-pressure hot wash | IP69K | wash pressure, distance, temperature |

| Mixed chemical wash | IP66/67 + material spec | gasket and cable jacket compatibility |

A practical warning

Higher IP targets increase dependence on gasket quality, torque control, and service discipline. If the site maintenance team frequently opens the unit or changes cables, a realistic IP66/67 plus strict gland control often delivers better uptime than chasing IP69K in the wrong environment.

Next is the compliance question. Many teams expect ATEX/IECEx certificates to “include” IP. The truth is more nuanced, especially for dust protection by enclosure.

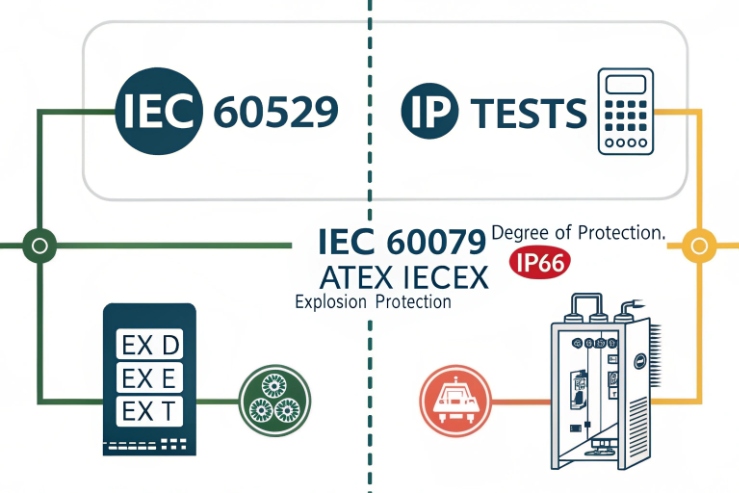

Do IEC 60529 tests and ATEX/IECEx certificates state minimum ingress ratings for Zone 1/21?

Some buyers assume Zone 1 automatically means IP66. That assumption is risky. Ex compliance and ingress protection are linked in some cases and separate in others.

IEC 60529 defines IP testing, but ATEX/IECEx certificates usually focus on explosion protection. For gas Zone 1, IP is often a separate environmental rating. For dust Zone 21, ingress protection can be part of the protection concept when Ex t is used, so minimum dust-tight levels can become essential.

Zone 1 gas: IP is usually an environmental requirement

For gas hazards, protection concepts like Ex d and Ex e are focused on controlling ignition sources. The product can be certified for Zone 1 and still have different IP options depending on enclosure design and accessories. Many manufacturers test the enclosure to IEC 60529 and publish IP66 or IP67 in the datasheet and manual, but the explosion certificate itself is not always written as an IP guarantee for every installed configuration.

So for Zone 1 gas sites, the safe procurement method is:

-

require the correct Ex marking for Zone 1

-

require the IP rating as an explicit environmental requirement

-

require certified glands that preserve both Ex and IP

Zone 21 dust: ingress can become part of explosion protection

Dust zones add a key difference. If the protection concept is “protection by enclosure” for dust, the enclosure must prevent dust ingress to reduce ignition risk. In these cases, dust-tight protection is not only about weather. It is about safety. This is why dust approvals often require strong sealing performance and clear limits on cable entries and maintenance. For many, dust-tight enclosure protection 6 is a common target.

IEC 60529 test reports vs certificates

IEC 60529 tells how IP is tested. A test report can prove IP66, IP67, or IP68 under defined conditions. A certificate proves the Ex protection method. These are related but not identical documents. The best tender pack includes both:

-

Ex certificate and marking

-

IP test evidence or statement from the manufacturer that the delivered configuration meets the IP rating

What to ask for in a tender

| Tender question | What to request | What it avoids |

|---|---|---|

| Is this phone valid for Zone 1 gas? | Ex marking and certificate | wrong category/EPL purchase |

| Is it valid for Zone 21 dust? | dust marking, EPL Db, group | gas-only product in dust zone |

| What is the IP rating as shipped? | datasheet + IP test statement | “IP depends on installation” argument |

| Does IP still hold with our cable plan? | gland list by cable OD and type | leaks after commissioning |

The practical rule is simple: treat IP as a separate requirement unless the dust protection concept makes enclosure sealing a safety feature. Then treat sealing as both safety and environmental fitness.

Now the last piece is the most important one in the field. Even the best enclosure fails if entries are wrong. That is why glands and installation practice decide the real IP level.

How do certified cable glands and installation practices maintain IP rating at entries and junctions?

Most ingress failures happen at the cable entry, not through the metal body. A perfect enclosure with a bad gland is still a leaking system.

Certified cable glands maintain IP rating only when they match the Ex concept, thread type, and cable outer diameter, and when installers follow correct stripping, torque, sealing washer, and unused-entry plug rules, with periodic inspection in harsh sites.

Choose glands like a mechanical component, not like a part number

A proper selection of certified cable glands 7 must match the entry thread, protection concept, and cable construction. If the cable OD is near the edge of the gland range, sealing becomes less stable over time. In harsh sites, it is better to choose a gland and insert that keeps the cable in the center of the sealing range.

Stopping plugs and reducers are part of sealing

Unused entries must be sealed with certified stopping plugs. A missing plug is an open door for dust and water. Reducers and adapters should be avoided unless the manual allows them. Every extra interface is one more leak path and one more corrosion point.

Installation discipline is the difference between “rated” and “real”

The best practices that keep IP consistent are simple:

-

do not nick the cable jacket under the gland

-

use the correct strip length so the gland grips the jacket, not inner insulation

-

apply correct torque and use the correct washer or sealing ring

-

add strain relief so cable pull does not work the seal loose

-

bond and earth the enclosure per site rules, and keep shield termination consistent for EMC

In offshore and refinery environments, vibration and temperature cycling can loosen hardware. A periodic inspection plan for glands and cover seals is realistic and cheap compared to emergency downtime.

Junctions and cabinets matter too

If the phone cable goes into a junction box or PLC cabinet, the IP chain is only as strong as the weakest box. Many site leaks happen in “nice-looking” junction boxes that were never tightened correctly. A strong project standardizes:

-

junction box IP rating

-

gland type and material (316L where salt exists)

-

inspection frequency

-

spare entry plug policy

| Ingress weak point | What to do | What it prevents |

|---|---|---|

| Gland sealing range mismatch | match gland to cable OD | slow leaks and IP drift |

| Wrong thread type | lock M/NPT in design | damaged entry and nonconformity |

| Unused entries | certified stopping plug | dust and water path |

| Poor torque control | torque procedure and tools | seal relaxation and vibration loosening |

| Cable damage | proper routing and strain relief | jacket cuts and wick paths |

| Corrosion at entry | suitable metal and coatings | seized glands and broken seals |

A simple acceptance test on site

After installation, a practical check is:

-

visual check of gland compression and plug seating

-

verify torque marks where used

-

confirm the cable jacket is intact at the entry

-

confirm the cover is seated evenly

-

confirm the phone remains functional after the first wash-down cycle

These checks are simple, but they reduce long-term failures more than any marketing claim about IP.

Conclusion

Most explosion-proof telephones target IP66 or IP67, while IP68 and IP69K are for true submersion or extreme washdown. The real IP rating depends on certified glands and disciplined installation.

Footnotes

-

Detailed overview of the ATEX directive and IECEx system for certifying equipment used in potentially explosive atmospheres. ↩ ↩

-

Learn how IP codes define the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies. ↩ ↩

-

Technical explanation of the IP67 standard for protecting sensitive industrial equipment against temporary immersion in water. ↩ ↩

-

Insights into the complex infrastructure and safety requirements of modern petroleum and chemical refinery process units. ↩ ↩

-

Understanding the mechanical stresses and sealing requirements for industrial equipment subjected to high-pressure cleaning routines. ↩ ↩

-

A guide to the design standards required to ensure that electrical enclosures remain completely sealed against fine particles. ↩ ↩

-

Overview of the critical role cable glands play in maintaining the ingress protection and safety of industrial devices. ↩ ↩