Outdoor calls often fail at the worst time. Rain gets into the mic, heat cracks the keypad, and dust kills the speaker. That is a safety risk.

A weatherproof telephone is a rugged phone built to keep working in rain, dust, sun, and cold by using sealed parts, tough materials, and an IP-rated enclosure.

A practical definition: “weatherproof” means the phone survives outdoors

A weatherproof telephone is not just a normal desk phone placed in a box. It is designed as a system where every weak point is controlled. The enclosure is sealed. Cable entry points use glands. The mic and speaker area use water-resistant membranes 1. The keypad is made to resist water, sand, and gloves. The goal is simple: keep voice clear and keep the device alive in outdoor abuse.

The core design features that matter

Weatherproof phones usually include corrosion-resistant parts and a stable housing. Many use aluminum alloy, stainless steel, or reinforced plastics. The gasket design matters as much as the shell. A good seal stays tight after years of thermal cycles, not just on day one. For sites with strong sun, UV resistance 2 is also a real requirement, because UV can make plastics brittle and can fade labels.

“Weatherproof” is not the same as “vandal-resistant”

Some projects mix the terms. Weatherproof targets water and dust. Vandal-resistant targets impact, prying, and abuse. Many outdoor emergency phones need both, but they are still different checks. If the site is public, a metal body, tamper-proof screws, and a protected handset cord (or handsfree design) become important.

Quick checklist for defining a true weatherproof phone

| Item | What to look for | Why it matters outdoors |

|---|---|---|

| IP rating | IP65/IP66/IP67+ depending on exposure | Controls water jets, rain, dust, and flood risk |

| Cable sealing | Glands + strain relief + sealed connectors | Most leaks start at cable entries |

| Audio protection | Water-resistant acoustic membrane | Keeps sound clear after rain and cleaning |

| Materials | Stainless/aluminum/UV-stable plastics | Fights rust, UV cracking, and aging |

| Mounting | Wall/pole mount options + drainage design | Avoids water pooling and loose installs |

| Service access | Simple internal layout and replaceable parts | Cuts downtime during field repair |

A short story that often fits here: a site chose “outdoor” phones with no real sealing, and the first storm caused dead keypads. After replacing them with proper IP-rated units and sealed cable glands 3, the failure stopped. This kind of lesson is common in outdoor deployments.

If the goal is emergency calling, weatherproof is not optional. It is the baseline for reliability.

The next step is choosing the right IP rating, because “outdoor” can mean many things.

What IP rating should a weatherproof phone have for outdoor sites?

Many outdoor phones die because the IP rating was chosen by guesswork. Light rain is not the same as wind-driven rain or washdown.

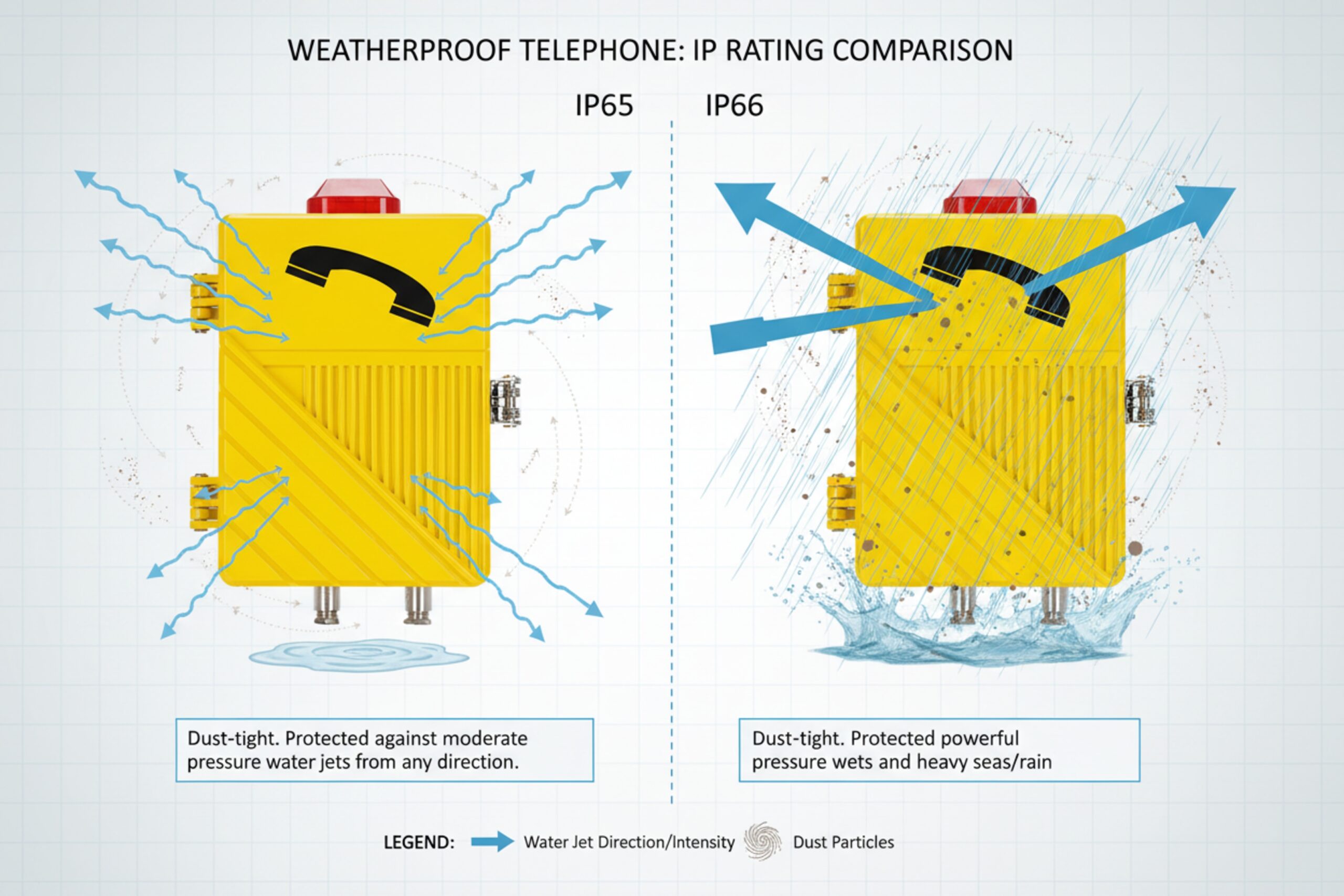

For most outdoor sites, IP65 or IP66 is a safe baseline, and IP67 is better if flooding or standing water can happen near the unit.

Start from the site, not the catalog

IP ratings describe protection against solids and water ingress. The right level depends on the Ingress Protection 4 rating required by the real exposure:

-

A covered loading dock has less water risk than a roadside pole.

-

A coastal site has salt mist, which increases corrosion risk.

-

A factory yard may use high-pressure cleaning, which changes the water threat.

-

A subway entrance may see splash and occasional flooding.

A simple mapping that works in real projects

| Outdoor condition | Typical risk | Practical IP target |

|---|---|---|

| Under canopy, low dust | Drips, light rain | IP54–IP55 (only if sheltered) |

| Open air wall/pole | Wind-driven rain, dust | IP65 |

| Heavy rain + washdown | Water jets, cleaning | IP66 |

| Flood-prone, low mounting | Temporary immersion | IP67 |

| Frequent submersion | Water stays above device | IP68 (only if truly needed) |

What most integrators miss

1) Cable entry is part of the IP rating in real life. If the gland or conduit is not sealed, the box rating does not save the phone.

2) Condensation can be a silent killer. Temperature swings can pull moisture inside if the design has weak seals or wrong venting.

3) Maintenance events break seals. If technicians open a unit often, the gasket and closing torque matter. A phone that is easy to service without damaging the seal is worth more than a higher spec on paper.

My rule for outdoor emergency points

For roadways, campuses, parking lots, and public walkways, IP65/IP66 is usually the minimum target. If the unit is low to the ground or near drainage paths, IP67 is a safer choice. It is also smart to add corrosion resistance and UV-stable labels, because outdoor failures are not only about water.

Next, many buyers ask if weatherproof is the same as explosion-proof. It is not, and mixing them can create safety gaps.

How do weatherproof telephones differ from explosion-proof models?

Buying the wrong “rugged phone” can create compliance trouble. A unit can survive rain but still be unsafe in hazardous gas zones.

Weatherproof phones block water and dust, while explosion-proof phones are certified to prevent ignition in hazardous areas and must meet strict safety standards.

The main difference is the hazard being controlled

A weatherproof phone is built for the environment: rain, dust, salt, and temperature. An explosion-proof phone is built for hazardous areas 5 where flammable gas or dust may exist. In those zones, a spark, hot surface, or internal fault can ignite the atmosphere. So the design must control ignition risk, and it must be verified by certification.

What changes inside the product

Explosion-proof models often use:

-

Flameproof enclosures 6 or increased safety designs, depending on the protection method

-

Tight control of surface temperature (temperature class)

-

Certified cable entries and approved glands

-

Special PCB spacing, fusing, and power limits

-

Strict manufacturing and traceability rules

Weatherproof models focus more on:

-

Sealing, drainage control, and membrane design

-

Corrosion and UV resistance

-

Audio stability in rain and wind

-

Fast field service without losing the seal

A clear comparison table for project decisions

| Topic | Weatherproof phone | Explosion-proof phone |

|---|---|---|

| Primary purpose | Keep working in rain/dust | Prevent ignition in hazardous zones |

| Key standard focus | IP ingress protection + durability | Hazardous area certification (ATEX 7/IECEx/UL, depends on region) |

| Typical enclosure | Sealed metal or reinforced plastic | Heavy-duty certified enclosure, often thick metal |

| Cost drivers | Seals, materials, corrosion design | Certification, safety design, special parts, compliance audits |

| Common locations | Outdoors, public areas, industrial yards | Refineries, chemical plants, gas stations, dust risk areas |

| Wrong choice risk | Short life, water damage | Major safety and compliance risk |

How to avoid confusion in specs

A phone can be both weatherproof and explosion-proof, but the explosion-proof requirement usually drives the whole design. If a site is not classified as hazardous, an explosion-proof phone may be overkill and can raise cost without adding value. If a site is hazardous, “weatherproof only” is not acceptable, even if it looks tough.

Many outdoor projects are not hazardous zones, but they still need reliable SIP features. That brings the next question: PoE and remote management.

Can a weatherproof SIP phone support PoE and remote management?

Outdoor devices are often hard to reach. If every change needs a ladder and a technician, the project gets expensive fast.

Yes. Many weatherproof SIP phones support PoE for single-cable power and data, and they can be managed remotely through auto-provisioning, web tools, and platform APIs.

Why PoE is a big deal outdoors

Power over Ethernet 8 reduces field work. One Ethernet cable can deliver network and power. That cuts the need for local power supplies and reduces points of failure. For pole-mounted emergency phones, PoE often makes the install clean and fast. It also helps when sites need battery-backed power from a central UPS in a network room.

What “remote management” should include in real projects

Remote management is not one feature. It is a set of tools that reduce service time:

-

Auto-provisioning: push configs by HTTP/HTTPS/TFTP/FTP (depends on device support)

-

Remote firmware upgrade: staged rollouts to avoid mass downtime

-

Central phonebook and hotline settings: standard for emergency calling

-

Health monitoring: registration status, network status, and device logs

-

API/HTTP control: useful for platform integration, such as access control and dispatch systems

-

Syslog/SNMP (if supported): for NOC monitoring and alerting

A practical feature checklist for outdoor SIP deployments

| Feature | What to ask for | Why it matters |

|---|---|---|

| PoE | 802.3af/at support (as required) | One cable install, central UPS power |

| Provisioning | HTTPS + template support | Secure, fast mass deployment |

| Remote upgrade | Signed firmware + scheduling | Avoid bricking devices and control downtime |

| Network | VLAN, QoS, DHCP options | Stable voice under network load |

| Security | TLS/SRTP options | Protects signaling and audio |

| Integration | HTTP API, dry contact I/O (optional) | Triggers, alarms, and platform linkage |

Field reality: sealing and PoE must coexist

Outdoor SIP phones need sealed RJ45 paths or sealed pigtails to keep IP protection intact. The best design treats Ethernet entry like a high-risk leak point. If the connector area is weak, the unit can be “IP66 on paper” but fail after the first rainy season.

From my OEM/ODM work, the strongest outdoor rollouts are the ones that treat management as part of the product, not an extra. A device that supports bulk provisioning and remote logs can save more money than a small hardware discount.

Now let’s talk about where these phones are actually used, because location drives both spec and feature needs.

Where are weatherproof emergency phones commonly installed?

Emergency phones look simple, but the site choice decides if they help or become a dead box on a pole.

Weatherproof emergency phones are commonly installed in parking areas, campuses, tunnels, transit points, industrial yards, roadsides, and remote gates where people need fast help in bad weather.

Public safety locations

Many deployments focus on areas with foot traffic and higher risk:

-

University campuses and dorm walkways

-

Parking lots and parking garages (entrances and pay stations)

-

Parks, trails, and public waterfront areas

-

Stadium perimeters and event venues

These sites often choose handsfree models, bright indicators, and simple “one-button call” behavior. Clear signage and high audio volume matter, because stress and noise reduce user accuracy.

Transport and infrastructure locations

Weatherproof emergency phones are common in:

-

Roadside points and service areas

-

Bridges and tunnels (including maintenance corridors)

-

Rail platforms and station entrances

-

Airports and perimeter roads

These sites need loud audio, strong wind noise control, and strong sealing against dust and exhaust residue. Some projects add beacons or strobe lights to help responders locate the caller fast.

Industrial and utility locations

Not every industrial site is hazardous, but many are harsh:

-

Power plants and substations (non-hazardous zones)

-

Water treatment facilities

-

Ports, shipyards, and coastal logistics yards

-

Warehouses and outdoor loading zones

Here, corrosion resistance, glove-friendly controls, and remote monitoring become key. Some sites also need relay outputs to trigger sirens or lights when a call starts.

Location-to-feature mapping table

| Installation site | Main environmental threat | Helpful phone features |

|---|---|---|

| Parking lots | Rain + vandal risk | Metal body, IP66, tamper screws, hotline |

| Campuses | Sun + frequent use | UV resistance, clear labels, auto-provisioning |

| Tunnels | Dust + noise | High SPL speaker, sealed mic, remote diagnostics |

| Coastal ports | Salt mist | Anti-corrosion materials, sealed glands, coatings |

| Utility yards | Wide temperature swings | Stable gasket design, monitoring, surge protection |

One last practical point: emergency phones also need a clear calling path. In Session Initiation Protocol 9 systems, that means stable registration, QoS, and a tested call route to a control room, security desk, or Public Safety Answering Point 10 gateway. Hardware alone does not complete the safety chain.

Conclusion

A weatherproof telephone is built to stay online outdoors. Choose the right IP level, do not confuse it with explosion-proof needs, and use PoE plus remote tools to keep service simple.

Footnotes

-

Specialized vents that allow sound transmission while blocking water and dust ingress. [↩] ↩

-

Material ability to withstand degradation and cracking from long-term sunlight exposure. [↩] ↩

-

Mechanical seal devices used to secure cable ends and maintain enclosure integrity. [↩] ↩

-

A standard rating system defining levels of sealing effectiveness against solids and liquids. [↩] ↩

-

Locations where flammable gases, vapors, or dusts create potential explosion risks. [↩] ↩

-

Housings designed to contain internal explosions without igniting the surrounding atmosphere. [↩] ↩

-

European regulatory directives controlling equipment used in potentially explosive environments. [↩] ↩

-

Technology delivering data and electrical power over a single twisted-pair Ethernet cable. [↩] ↩

-

The standard signaling protocol used for initiating and managing voice and video sessions. [↩] ↩

-

A call center responsible for answering emergency calls and dispatching emergency services. [↩] ↩