Corrosion can quietly destroy a hazardous-area phone. When the case pits and the gland leaks, the phone may fail during an emergency.

A corrosion “rating” comes from standards-based evidence: coating class (ISO 12944), salt-fog hours (ISO 9227/ASTM B117), and chemical compatibility tests on the full build, not only raw materials.

Corrosion Resistance Is Proven by a Test Package, Not a Single Number

Why one label never tells the full story

Many buyers ask for one simple label like “C5” or “2000 hours.” That sounds clear, but it is not enough. Corrosion protection is a stack. The stack includes metal choice, coating system, fasteners, gasket compounds, cable jacket, and gland materials. The weak part sets the real life of the product. A 316L enclosure still fails if the cable gland uses the wrong alloy. A strong powder coat still fails if the edge prep is poor. A perfect lab test still fails if the site uses aggressive cleaning chemicals that were never listed.

A better approach is to define corrosion resistance like a “passport.” The passport has three pages:

1) Atmospheric corrosion class for the coating system and environment.

2) Salt-fog or cyclic corrosion evidence for offshore and coastal zones.

3) Chemical compatibility evidence for oils, solvents, acids, and alkalis that touch the phone.

This approach also protects IP66/67 1 and IK10 2. Corrosion and sealing are linked. Pitting can create leak paths. Swollen gaskets can lose compression. Rust at threads can change torque and crack coatings. A phone can still be “Ex certified” on paper and become unsafe to maintain if bolts seize and covers cannot be opened correctly.

How I write a “rating” in a way that works for EPC and end users

In most refinery and offshore RFQs, the most useful output is a short table that ties each standard to a test deliverable. It removes debate and speeds up approvals.

| What you want to prove | Standard family | What the report should show | What it protects |

|---|---|---|---|

| Environment class | ISO 12944 C1–C5/CX | Coating system, DFT, surface prep, durability class | Long-term exterior life |

| Salt exposure | ISO 9227 / ASTM B117 | Hours, defect evaluation, blister/rust creep notes | Coastal/offshore performance |

| Real chemicals | NACE / ASTM immersion 3 | Fluid list, time/temp, property changes | Gaskets, cable, labels, finish |

This “rating” format is easy to copy into a spec and easy to verify in a FAT package. It also keeps vendors honest because the same lab methods can be repeated later.

A corrosion claim becomes meaningful only when it is linked to the exact configuration shipped, including the gland, fasteners, keypad, and gasket compound. The next sections show the standards, the right material choices, and a clean way to write offshore and refinery requirements.

Now let’s move from the idea of “rating” to the exact standards and test evidence that buyers ask for.

Which standards quantify corrosion resistance—ISO 12944 C1–C5/CX, ISO 9227 or ASTM B117 salt spray hours, and NACE or ASTM chemical immersion?

Vague words like “anti-corrosion” create disputes. A project needs measurable proof that matches the site.

ISO 12944 sets the environment and coating system class, ISO 9227 or ASTM B117 gives salt-fog exposure evidence, and NACE/ASTM immersion tests confirm chemical compatibility for metals, coatings, and elastomers.

…ISO 12944: a coating and environment language that spec teams understand

ISO 12944 4 is useful because it speaks in site terms. It frames corrosion risk classes like C3, C4, C5, and the newer CX for very harsh offshore or industrial coastal exposure. It also pushes the conversation to coating systems, surface prep, and expected durability. This matters because coating performance is not only the paint type. It is also blasting, profile, cleaning, and film thickness control.

For an explosion-proof telephone, ISO 12944 is often used to define what happens on the outside surface. It does not replace chemical compatibility testing. Still, it creates a clear baseline for “this phone belongs in this atmosphere class.”

ISO 9227 and ASTM B117: salt-fog as a screening test, not a lifetime promise

ISO 9227 5 and ASTM B117 6 are salt spray (salt fog) exposure methods. They are common in offshore and coastal specs because they are easy to run and easy to compare. Still, salt fog is a steady exposure. Real offshore corrosion is often cyclic. Wet-dry cycling and UV can change results. This is why many serious specs add a cyclic test or a combined UV + corrosion cycle.

Salt-spray hours also need a clear pass definition. “1000 hours” means nothing if you do not define allowed rust creep from a scribe, blistering limits, and edge behavior. A coating can look good until the first scratch, and then rust creeps under the film.

NACE and ASTM chemical immersion: the missing proof for refineries

Refineries care about chemicals that touch the phone. This includes oils, fuels, solvents, and cleaning agents. Chemical immersion or exposure tests prove if gaskets swell, if keypad elastomers soften, and if coatings discolor or lose adhesion.

For a phone, the chemical tests should cover:

- gasket compound (main cover seal and keypad seal)

- cable jacket and cord strain relief

- label ink and adhesive

- …powder coat or fluoropolymer topcoat

- stainless fasteners and inserts where galvanic risk exists

| Standard block | Best use | Main limitation | How I fix the limitation |

|---|---|---|---|

| ISO 12944 | Defines site class and coating plan | Does not test specific plant fluids | Add chemical exposure list |

| ISO 9227 / ASTM B117 | Fast comparison of salt resistance | Not a full offshore simulation | Add cyclic corrosion and UV |

| NACE / ASTM immersion | Verifies real fluid compatibility | Needs correct fluid list | Require site fluid matrix from end user |

When these three blocks are combined, the “corrosion rating” stops being a marketing claim and becomes a test-backed statement that fits offshore and refinery projects.

Which materials and coatings suit harsh chemicals—316L stainless, GRP, powder-coated aluminum, fluoropolymer/PTFE, marine-grade fasteners, and acid/alkali-resistant gaskets?

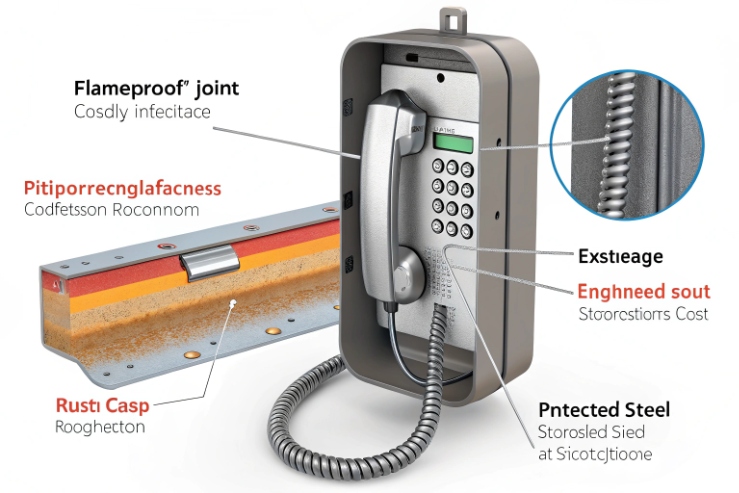

A phone fails at the weakest material in the chain. A perfect enclosure still fails if one gasket turns soft.

316L stainless and well-made GRP handle many harsh sites, powder-coated aluminum needs strong edge control, and fluoropolymer top layers plus marine-grade fasteners and oil/acid-resistant gaskets protect the full assembly.

316L stainless: strong default, but only when the details match

316L is often chosen for offshore and refineries because it resists many corrosion mechanisms and keeps mechanical strength over time. It also tolerates frequent cleaning. Still, 316L stainless 7 is not “immune.” Crevice corrosion can appear when salt deposits stay wet in a gap. Chlorides are the common trigger. This is why seam design, drain paths, and surface finish matter.

A stainless enclosure still needs:

- correct fastener alloy selection

- correct gasket compound for oils and solvents

- correct cable gland material to avoid galvanic couples

GRP: great chemical stability when resin and UV strategy are correct

GRP 8 can perform very well in chemical zones because it does not rust. It can also reduce galvanic issues. Still, GRP performance depends on resin type and UV stability. If the phone sits outdoors, UV can chalk the surface and weaken some plastics over time. A good GRP spec includes UV resistance and color stability requirements.

GRP also needs careful insert design. If an insert loosens, the seal load changes and IP risk rises.

Powder-coated aluminum: viable, but it needs disciplined coating control

Powder-coated aluminum can work in many industrial zones. The risk is edge creep and underfilm corrosion at scratches. A good system controls:

- surface prep (degrease + conversion coat)

- …film thickness (DFT) range

- cure control

- edge coverage

For very harsh offshore zones, a duplex system (primer + topcoat) or a fluoropolymer top layer can help.

…Fluoropolymer / PTFE-based strategies: strong chemical barrier where it counts

Fluoropolymer coatings 9 can reduce chemical attack and make cleaning easier. …PTFE-like surfaces can reduce adhesion of oils and dirt. These are useful on front faces and touch areas. Still, coatings must not interfere with grounding paths and Ex assembly rules. A good design keeps conductive bonding points clear while protecting broad exposed surfaces.

Fasteners and gaskets decide sealing life

Many field failures come from fasteners and seals, not the enclosure.

| Part | Offshore/refinery best practice | Why it matters |

|---|---|---|

| Fasteners | Marine-grade stainless, matched to housing | Stops rust lock and cover damage |

| Cable glands | Material matched to housing + site chemicals | Prevents leaks and seized threads |

| Main gasket | FKM/fluorocarbon for oils and fuels | Controls swell and compression set |

| Acid/alkali zones | Choose gasket compound by fluid list | Avoids softening and cracking |

In my OEM work, the fastest way to reduce corrosion risk is to lock the material stack early. When a project changes one small part, like a gasket compound for cost, the “rating” can change more than the buyer expects.

How should offshore and refinery specs be written—salt-spray ≥1,000–2,000 h, cyclic corrosion, UV exposure, and chemical compatibility reports from accredited labs?

A spec that only says “marine grade” creates delays. A spec that lists methods and evidence moves fast.

A strong spec states the environment class, minimum salt-spray hours plus cyclic corrosion, UV exposure when outdoors, and a chemical compatibility report from an accredited lab for gaskets, coatings, glands, and cable jackets.

Write the requirement as a checklist with acceptance rules

Offshore and refinery specs work best when they read like a small test plan. This avoids “pass by statement.” It also keeps suppliers aligned on what is included in the test sample.

Here is a clean way to write it:

- Declare the intended environment: offshore open deck, coastal outdoor, refinery process area, or indoor control room.

- …Set the coating class language: ISO 12944 class and durability target.

- Set salt-fog evidence: ISO 9227 or ASTM B117 hours, with a defined evaluation method.

- Add cyclic corrosion if the zone is offshore or splash-prone.

- Add UV exposure if the phone is outdoors or sun-exposed.

- Require a chemical compatibility report for the exact site fluids.

Make the salt-spray line useful

If the spec says “≥1,000–2,000 hours,” it should also say what is allowed after exposure. Many projects use scribed samples. The report should show rust creep from a scribe, blistering, and coating adhesion behavior. It should also show that markings stay readable and that the keypad remains usable.

Demand “as-built” evidence from accredited labs

A good report package is not only material datasheets. It is an “as-built” report on the exact configuration:

- enclosure and coating system

- fasteners

- gland model and material

- gasket compound

- cable jacket type

- keypad elastomer type

| Spec line item | Minimum content | Common mistake |

|---|---|---|

| Salt-spray hours | Hours + evaluation criteria | Hours listed without pass limits |

| Cyclic corrosion | Cycle type + total cycles | No cycle, only steady fog |

| UV exposure | Hours + acceptance for color/labels | Outdoor phone tested without UV |

| Chemical report | Fluid list + time/temp + changes | Report uses wrong fluids |

| Lab status | Accredited lab, traceable conditions | In-house test with no trace |

Add a fluid matrix to stop guessing

Refinery chemical risk is site-specific. A simple matrix in the RFQ solves this. It lists fluid name, concentration, temperature, and contact mode (splash, wipe, mist). The supplier then tests gaskets, cable jackets, and finishes against that matrix.

This style of spec also protects procurement. It turns “corrosion rating” into a deliverable set that can be checked before shipment. It also reduces the risk that corrosion protection fails after a few months due to one unlisted solvent.

Will corrosion protection preserve ATEX/IECEx, IP66/67, and IK10 over life—gland metals, cable jackets, and gasket compounds matched to solvents and oils?

A phone can keep its Ex label and still become unsafe to maintain if corrosion locks the cover or breaks the seal.

Corrosion protection can preserve ATEX/IECEx, IP66/67, and IK10 only when metals, glands, cable jackets, and gasket compounds are matched to the real chemicals, and when sealing load and impact strength remain stable over time.

Corrosion changes mechanical behavior, not only appearance

A corroded fastener can seize. A seized fastener can lead to improper opening and closing. Then the flamepath or sealing line can be damaged. This is a real life risk in hazardous areas. The phone may still be certified, but maintenance becomes risky.

Corrosion can also reduce IK performance over time. If coatings crack, if GRP chalks and becomes brittle, or if metal pits deeply, impact behavior can change. A phone designed for IK10 should keep that integrity in the real atmosphere, not only on day one.

IP66/67 depends on seal chemistry and steady compression

To preserve IP66/67 over life, the seal must keep its elasticity. Oils and solvents can swell elastomers, then cause compression set. That reduces sealing force. Cable glands are often the first leak point because they see chemical exposure and mechanical pull at the same time.

Cable jackets matter more than many buyers expect. Some jackets soften in oils. Some crack in UV. When the jacket fails, the gland seal and strain relief fail too.

Match every “wet” material to the chemical list

A practical life plan uses a compatibility table across all wetted parts.

| Part exposed to chemicals | Typical failure mode | What to demand |

|---|---|---|

| Gasket compound | Swell, compression set, leak | Compatibility report by fluids |

| Cable gland | Thread corrosion, seal softening | Material match + test evidence |

| Cable jacket | Softening, cracking, slip | Jacket spec matched to oils/UV |

| Fasteners | Seize, rust staining, cover damage | Marine-grade fasteners and anti-seize plan |

| Keypad | Sticky surface, unreadable text | Oil/solvent-resistant elastomer + ink |

Preserve Ex integrity by keeping assembly stable

Ex integrity depends on correct assembly and correct maintenance. Corrosion protection helps if it keeps:

- cover bolts operable

- sealing line clean

- bonding points intact

- labels and markings readable

- glands tight and compatible

In my experience, the best way to protect ATEX/IECEx 10 and IP over life is to treat corrosion as a maintenance topic, not only a design topic. A simple inspection schedule for glands, gaskets, and fasteners prevents small corrosion from turning into a major failure. When a site uses strong degreasers, the cleaner list must be controlled. If the cleaner dissolves a gasket slowly, the phone will fail no matter how strong the metal is.

Conclusion

A real corrosion “rating” is a verified package: ISO 12944 class, salt and cyclic corrosion proof, and chemical compatibility reports that protect Ex integrity, IP66/67 sealing, and IK10 strength over life.

Footnotes

-

Ingress Protection ratings ensuring equipment is dust-tight and protected against water jets or immersion. [↩] ↩

-

Highest impact protection rating, certifying resistance to 20 joules of mechanical impact. [↩] ↩

-

Protocols for testing material compatibility with specific industrial chemicals and environments. [↩] ↩

-

International standard defining corrosion protection classes and durability for steel structures. [↩] ↩

-

Standardized salt spray tests to evaluate corrosion resistance of metallic materials. [↩] ↩

-

Standard practice for operating salt fog apparatus to test corrosion resistance. [↩] ↩

-

Low-carbon austenitic stainless steel known for superior corrosion resistance in marine environments. [↩] ↩

-

Glass Reinforced Plastic, a composite material offering high chemical and weather resistance. [↩] ↩

-

High-performance coatings providing exceptional chemical resistance and low friction properties. [↩] ↩

-

Certification standards ensuring equipment safety in explosive atmospheres. [↩] ↩