Weatherproof telephones sit in rain, salt, dust and vandal-prone sites. If the entry thread is wrong, the IP66/IP67 rating fails long before the electronics do.

Most weatherproof telephones use metric threads like M20×1.5 or M25×1.5 for cable glands, plus 1/2" NPT options for North America. The right choice depends on region, conduit system and sealing method.

When we design an outdoor or industrial telephone, pipe threads look like a small detail. But this “small” detail decides if the enclosure actually stays dry, if the installer can finish the job without extra adapters, and if the certification report still applies. So it is worth slowing down and choosing the thread standard, size and sealing method with intention.

Should 1/2" or 3/4" NPT, or M20/M25 metric entries be specified?

Many specifiers struggle with a basic choice: NPT or metric, and which size. If the entry is too small, installers fight with tight bends and reducers. If it is too big, you add cost, bulk and more leak paths.

For global weatherproof telephones, I usually treat M20×1.5 as the default, add M25×1.5 for larger cables, and offer 1/2" NPT options where North American conduit rules apply.

Regional preferences and typical patterns

From project experience, a simple pattern works well:

-

In Europe, Middle East, most of Asia and South America, metric cable glands dominate. M20×1.5 is the workhorse for IP66/IP67/IP68 glands on control boxes, beacons and telephones.

-

M25×1.5 shows up when the cable is thicker, or when you want two or three cables through one gland insert.

-

In North America, electricians still think in trade sizes. 1/2" NPT 1 is the default conduit entry on hazardous and weatherproof telephones. 3/4" NPT appears when the conduit is larger or many conductors share the same raceway.

So one very practical enclosure strategy is:

-

Standard boss: M20×1.5 2, because this covers most of the world with common metric glands.

-

Optional boss or second variant: 1/2" NPT, to plug straight into EMT/RMC systems without adapters.

-

Extra large option (M25 or 3/4" NPT) only when drawings show thick armored cable, multi-core power plus data, or future expansion.

This way, stock is simple, but local installers still feel at home.

Sizing around cable diameters

The best starting point is not the thread. It is the cable outside diameter and how many cables share each entry.

Typical patterns in real projects:

-

One Cat5e/Cat6 and nothing else: M20 or 1/2" NPT is enough.

-

One Cat6 plus a separate power cable: still often okay with M20, but M25 gives more bending space.

-

Armored cable or very thick UV-resistant jackets: step up one thread size, or use two separate entries.

Cable gland datasheets usually show the clamping range for each thread size, for example:

-

M20 gland: about 6–12 mm or 10–14 mm cable OD, depending on insert.

-

M25 gland: often extends to 18 mm or more.

So a simple rule that keeps many projects safe is:

-

Design for the largest realistic cable OD, not the minimum in the current tender.

-

If you are close to the top end of the gland range, move up from M20 to M25, or from 1/2" NPT to 3/4" NPT, rather than over-tightening the seal.

Example comparison of common thread choices

| Thread standard | Typical entry size | Main regions / habits | Typical role on weatherproof telephone |

|---|---|---|---|

| Metric ISO | M20×1.5 | EU, Asia, Middle East, global | Default cable gland entry for IP66/IP67 housings |

| Metric ISO | M25×1.5 | Global | Larger cables, multi-cable glands, armored cable |

| NPT | 1/2" NPT | USA, Canada, some LATAM | Standard conduit entry, often two per enclosure |

| NPT | 3/4" NPT | USA heavy industry, refineries | Large conduit, multi-circuit feeds |

| BSPP | G 1/2 | UK, parts of EU and Commonwealth | Parallel gland threads on some industrial enclosures |

The actual “correct” choice is not a single magic size. It is a match between cable OD, regional practice, and how you want installers to land their conduit or glands without extra reducers.

Are BSPP/G or BSPT/R threads acceptable with proper glands and locknuts?

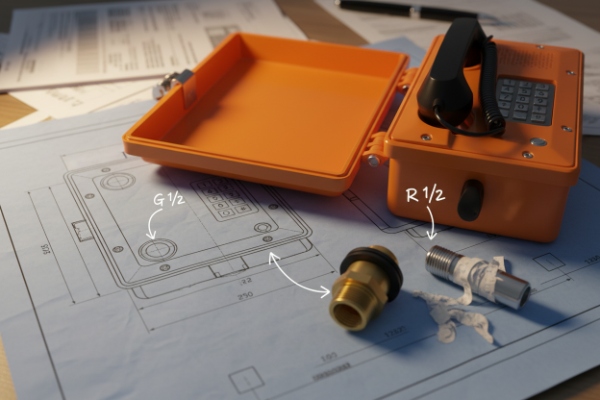

On many European drawings, the thread is marked as “G 1/2” or “R 1/2”. Installers then worry about mixing BSP with NPT or metric, and whether this will break the IP rating.

Yes, BSPP (G) and BSPT (R) threads are normal on industrial enclosures. They work well when you use matching glands, locknuts and sealing washers that are tested for the target IP rating.

Where BSPP/G and BSPT/R show up

British Standard Pipe threads are still very common on control panels, junction boxes and some telephones that come from the UK or Commonwealth countries. In this family:

-

BSPP (British Standard Pipe Parallel) 3 is the parallel form and is usually labeled “G” on drawings.

-

BSPT (British Standard Pipe Taper) 4 is the tapered form and is usually labeled “R”.

These threads are not just “old British stuff”. They are still widely used in hydraulics, pneumatics and outdoor equipment. So it is normal to see a weatherproof telephone with G 3/4 entries in some markets.

The important point is that BSP is its own system. It uses a 55° thread angle, and the pitches differ from NPT. So a BSP fitting is not meant to seal properly in an NPT hole, and the opposite is also true.

Sealing with BSPP (parallel) vs BSPT (tapered)

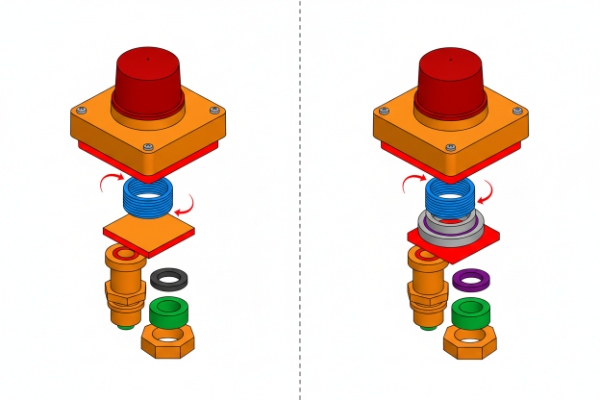

The sealing strategy depends on the thread form:

-

BSPP / G (parallel)

-

The thread itself does not make the seal.

-

The seal is at a washer or O-ring face, either under the gland shoulder or under a locknut on the inside of a clearance hole.

-

A flat, clean enclosure face and the right thickness washer are critical.

-

-

BSPT / R (tapered)

-

The metal-to-metal interference helps sealing, similar to NPT.

-

You still need a suitable sealant (PTFE tape or compound) approved for the application.

-

Over-tightening can crack plastic or thin-wall housings.

-

The safest practice on a telephone project is:

-

Use BSP cable glands and accessories in BSP holes.

-

Use sealing washers that are rated and tested for IP66/IP67 between the gland and the enclosure.

-

Avoid “thread-mixing” like NPT male into BSPP female, even if it “kind of fits” by feel.

Quick summary of BSP thread options for telephones

| Thread type | Marking on drawings | Form | Typical sealing method | Good practice on IP66/IP67 phones |

|---|---|---|---|---|

| BSPP | G 1/2, G 3/4, etc. | Parallel | Washer or O-ring under gland shoulder | Use sealing washer and locknut if needed |

| BSPT | R 1/2, R 3/4, etc. | Tapered | Thread sealant on metal-to-metal flank | Use approved sealant and avoid over-torque |

| Mixed BSP | R male into G female | Taper + P | Thread plus washer at end face | Follow gland maker’s installation guidance |

So BSPP/G and BSPT/R entries are not a problem by themselves. They are only a problem when mixed with other thread standards or when the required sealing hardware is missing.

Do thread adapters or reducers impact IP66/IP67 sealing or certification?

On site, people often reach for a thread adapter to “fix” a mismatch between a telephone entry and whatever gland they have in stock. Mechanically it works, but the paperwork may say something else.

Adapters and reducers are only safe when they carry the same IP and Ex approvals, and when you keep proper washers or O-rings between every threaded interface in the sealing chain.

What an adapter changes in the sealing chain

With a simple gland in a tapped hole, there is one main interface:

-

Enclosure thread ↔ gland entry thread

-

Gland sealing ring ↔ cable jacket

When you add an adapter or reducer 5, you create extra joints:

-

Enclosure thread ↔ adapter external thread

-

Adapter shoulder ↔ enclosure face (or locknut and washer)

-

Adapter internal thread ↔ gland thread

-

Gland sealing ring ↔ cable jacket

Each of these joints must now respect the same IP rating. If even one of them leaks, the enclosure leaks. In practice, that means:

-

A face seal (O-ring or flat sealing washer) under the adapter shoulder, not just metal-to-metal contact.

-

Proper engagement length of the adapter thread into the enclosure, so the joint is strong and sealed.

-

The gland still has its own washer or O-ring under its shoulder, unless the adapter is designed as a combined solution.

Certification and Ex / hazardous area concerns

Things get stricter when the telephone is certified for hazardous areas, for example ATEX, IECEx, UL Class I Division 2:

-

Many adapters on the market are specifically approved as Ex components. They come with their own part number, documents and often include an O-ring for the face seal.

-

If you use an unapproved adapter on a certified telephone, you may lose the Ex rating, even if the mechanical IP sealing looks fine.

-

Some certifications test a complete chain: enclosure + adapter + gland. When you change any part of that chain in the field, you step outside that tested configuration.

For non-hazardous outdoor phones, most owners still prefer to use adapters from well-known cable gland manufacturers, especially when IP66 or IP67 6 is specified in the contract.

Typical adapter scenarios and what to watch

| Scenario | Main risk | Better practice |

|---|---|---|

| M20 boss → 1/2" NPT adapter → NPT gland | Missing face seal at adapter shoulder | Use adapter with O-ring and add sealing washer if needed |

| 1/2" NPT boss → reducer → M20 metric gland | Too many joints, hard to inspect | Prefer a single correct NPT gland or Ex-rated adapter |

| Ex d enclosure → generic brass adapter | Loss of explosion-proof certification | Use adapter listed in the Ex approval documents |

| Outdoor IP67 phone → cheap unmarked adapter | Unknown material, no tested IP performance | Use adapter from recognized gland manufacturer |

Adapters and reducers are not forbidden. They just change the focus from simple “thread fits” to “entire sealing chain stays inside the tested and approved envelope”.

What torque, sealing washer, and thread sealant should installers apply?

Many IP problems do not come from the thread standard at all. They come from a gland that is too loose, over-tightened, or installed without the sealing washer or the right compound on the threads.

Installers should follow the cable gland datasheet for torque, use the sealing washer supplied, and apply only manufacturer-approved tape or compound on tapered threads.

Torque: start from the gland datasheet

Every serious cable gland manufacturer publishes recommended tightening torques. These values depend on:

-

Thread size

-

Material (plastic vs brass vs stainless steel)

-

Seal design and cable clamping range

Typical M20 examples in real catalogues look like this:

-

Plastic M20 gland: torque values in the range of a few Nm for the dome nut and slightly higher at the entry.

-

Metal M20 gland: higher torque, often in the high single-digit to low double-digit Nm range.

Because the numbers vary between brands, the safe rule on a weatherproof telephone is:

-

Read the torque table in the gland datasheet, not a random rule of thumb.

-

Use a torque wrench 7, at least for the first unit in a batch, to give the team a real “feel” for the correct tightness.

-

Stop at the recommended range instead of “one more turn for safety”, which can crush the cable or damage the enclosure threads.

For NPT and BSPT tapered threads, some manufacturers give the number of turns past hand-tight as a guide. Follow that guidance if they provide it.

Washers, O-rings and sealants in real jobs

For parallel threads (metric, BSPP/G):

-

Always use the sealing washer 8 or O-ring specified for the gland.

-

On clearance holes with a locknut inside the enclosure, place the sealing washer on the outside face where water hits, not under the locknut inside.

-

Check that the enclosure face is flat, clean and free from paint lumps, weld beads or casting defects in the sealing area.

For tapered threads (NPT, BSPT/R):

-

Use PTFE tape 9 or a liquid thread sealant that is approved for the environment and the certification (some Ex gear forbids certain sealants).

-

Start the tape one or two threads back from the end, so no loose tape strand ends up inside the enclosure.

-

Do not mix tape and thick compound in a way that makes a big “plug” which can stress thin plastic boss walls.

For IP66/IP67 levels, think in layers:

-

Cable jacket seal: done by the cable gland 10 compression insert.

-

Gland-to-enclosure seal: done by a sealing washer, O-ring, or tapered thread plus sealant.

-

Any adapter interface: again, a dedicated face seal, not just bare metal contact.

A simple site checklist that works well on weatherproof telephones is:

-

Correct thread standard and size used.

-

Gland matches that thread and has the right IP rating.

-

Washer/O-ring is present and seated flat.

-

Torque applied within the manufacturer range.

-

Only approved sealant used, on tapered threads only.

When installers follow this checklist, the enclosure rating on paper is much more likely to match the reality on a rainy night.

Conclusion

When we line up the correct thread standard, entry size, adapter strategy and installation method, weatherproof telephones stay dry and reliable in the field, not just in the datasheet.

Footnotes

-

Explains the National Pipe Taper (NPT) standard used widely in North America for sealing pipes and fittings. ↩

-

Provides technical data on ISO metric threads, the global standard for general-purpose screw threads including M20 and M25. ↩

-

Describes the British Standard Pipe Parallel (BSPP) thread form and its sealing method using washers or O-rings. ↩

-

Details the British Standard Pipe Taper (BSPT) thread, where sealing is achieved through thread interference. ↩

-

Overview of thread adapters and reducers, explaining how they allow connection between different thread sizes and types. ↩

-

Defines the IP67 rating, indicating a device is dust-tight and protected against temporary immersion in water. ↩

-

Explains the importance of using a torque wrench to apply precise tightening force to fasteners and glands. ↩

-

A guide to different types of washers, including sealing washers used to prevent fluid or gas leakage. ↩

-

Instructions on how to properly apply PTFE thread seal tape to tapered pipe threads for a leak-proof joint. ↩

-

A technical guide to selecting the correct cable gland based on cable type, environment, and certification requirements. ↩