A phone can look rugged and still be unsafe in a hazardous zone. One wrong selection can stop operations and create real safety risk.

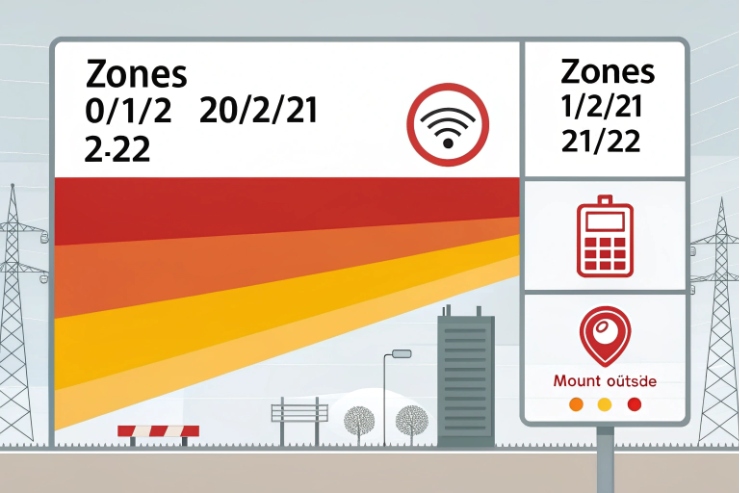

Explosion-proof telephones are suitable for classified gas and dust areas (like ATEX/IECEx Zones 1/2 1 and 21/22, or North American Class I Div 1/2) and for harsh industrial sites when the device marking matches the site classification and environment.

A practical way to choose the right hazardous area phone?

Start from the site classification, not from the product name

An “explosion-proof telephone” is a category, not a guarantee. The safe way is to match the phone certificate marking to the site classification. The site classification comes from your HSE team, EPC documents, or hazardous area dossier 2. The phone certificate tells exactly where it can be installed. If the phone marking does not match the zone or division, the project is at risk.

A good selection process uses four checks:

1) Hazard type: gas/vapor or dust.

2) Area level: Zone 1 vs Zone 2, or Div 1 vs Div 2.

3) Group: gas group (like IIC) or dust group (like IIIC).

4) Temperature class and ambient: T4–T6 and local temperature range.

Environmental factors come next. Many failures in the field are not ignition risks. They are uptime risks. Offshore salt, refinery wash-down, UV, vibration, and cable gland corrosion can stop a phone faster than the electronics.

Here is the quick checklist that helps buyers and integrators align fast:

| Decision item | What to confirm | Why it matters |

|---|---|---|

| Zone/Division | Zone 1/2 or Class I Div 1/2 | Controls installation legality |

| Gas/Dust group | IIA/IIB/IIC or IIIA/IIIB/IIIC | Controls ignition energy limits |

| Temp class | T4/T5/T6 and ambient rating | Prevents hot surface risk |

| Ingress & impact | IP66/67 and IK rating | Keeps it working after wash-down |

| Corrosion | 316L/GRP and test evidence | Preserves glands, screws, seals |

| Cabling | approved glands and cable type | Protects Ex and IP integrity |

A small personal note belongs here. In one early project, a site selected the right Zone rating, but the wrong cable gland material. The phone stayed certified, but water entered after months of hose-down. The fix was simple. The lesson was not. A hazardous-area phone must be treated like a system, not a single device.

Now the next sections answer the real questions most EPC teams ask: which zones are covered, how North American classes map, where these phones are typically deployed, and which environmental extremes define “suitable” for tunnels, pipelines, and tank farms.

If the selection is done right, the phone becomes boring. Boring is the goal in safety communications.

Do ATEX/IECEx Zones 1/2 and Zones 21/22 cover typical gas and dust hazards?

A lot of projects get stuck on one detail: “Is Zone 2 enough?” That question is valid because the wrong zone assumption can force rework.

Yes. ATEX/IECEx Zones 1/2 cover most typical gas and vapor hazards in industrial plants, and Zones 21/22 cover many dust hazards, as long as the site classification and gas/dust group match the device marking.

Gas zones in plain words

ATEX and IECEx use “Zones” to describe how often an explosive atmosphere is present:

-

Zone 0: explosive gas atmosphere is present continuously or for long periods.

-

Zone 1: likely to occur in normal operation.

-

Zone 2: not likely in normal operation, or only for a short time.

Most outdoor refinery and chemical plant locations are Zone 2, and some process areas near vents, pumps, and sampling points are Zone 1. Zone 0 is less common for phone mounting because it is often inside tanks or enclosed spaces. Still, some special applications exist.

Dust zones and what they mean for phones

Dust zones are similar in concept:

-

Zone 20: dust cloud present continuously or for long periods.

-

Zone 21: likely in normal operation.

-

Zone 22: not likely in normal operation, or only for a short time.

Zone 21 and 22 are common in grain handling 3, powder processing, and some mining and bulk material sites. Dust adds extra design concerns. Dust can block keypads, degrade seals, and raise surface temperature if it piles up. This is why dust-zone phones often need strong sealing design and clear cleaning procedures.

Gas and dust groups are not optional details

Zones are only half the story. The other half is the group marking:

-

Gas groups often appear as IIA / IIB / IIC.

-

Dust groups often appear as IIIA / IIIB / IIIC.

A phone marked for IIC is typically more demanding than one marked for IIA. The same idea applies for IIIC dust. If the site document says IIC or IIIC, the phone must match.

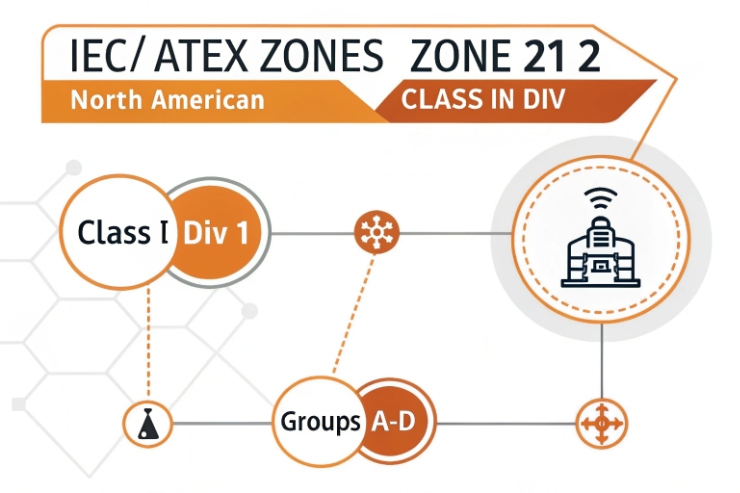

How do North American C1D1/C1D2 and Groups A–D/IIIC map to site classifications?

A global EPC team often asks for “one phone for all regions.” The problem is that “Zone” and “Division” systems are similar in intent but different in structure.

Class I Division 1/2 4 and gas Groups A–D roughly align with Zone risk levels, but the mapping is not exact. A safe spec lists both required markings and lets the AHJ accept the final installation.

What Class I Division 1 and 2 mean

In North America, the common system is:

-

Class I: flammable gases and vapors.

-

Division 1: hazard exists under normal operation, or frequently due to maintenance or leaks.

-

Division 2: hazard is not likely under normal operation, and if it happens it is short.

So the concept is close to Zones 1 and 2. Many engineers use these rough comparisons:

-

Div 1 ~ Zone 0/Zone 1 (depends on site details)

-

Div 2 ~ Zone 2

This is not a legal conversion table. It is a planning guide. The final acceptance depends on the local code path and the authority having jurisdiction.

Gas and dust group language differences

North America uses gas groups A, B, C, D for Class I, and dust groups under Class II and III frameworks. In modern practice you will also see conductive dust 5 described as IIIC. For global specs, the goal is simple: match the phone to the gas or dust severity required.

Are offshore platforms 6, chemical plants, refineries, and mines standard deployment environments?

Some buyers worry that “explosion-proof” is niche. In reality, these phones are most common in the exact industries where downtime costs money and safety risk is high.

Yes. Offshore platforms, FPSOs, refineries, chemical plants, mines, and bulk material sites are standard environments for explosion-proof telephones, because they combine hazardous atmospheres with harsh weather, noise, and long cable runs.

Offshore platforms and FPSOs

Offshore decks bring salt spray, constant vibration, UV, and wash-down. The phone must resist corrosion and keep seals tight. This is where 316L stainless or high-grade GRP often wins. A marine-grade gland and correct shield termination matter as much as the phone body. Many offshore teams also want loud ringers and strong sidetone because wind and machinery noise are constant.

Refineries and chemical plants

Refineries bring hydrocarbon mist, solvents, and frequent cleaning. The phone must resist oil contamination, gasket swelling, and chemical staining. Tank farms and loading areas often add strong sun and temperature swings. Process units often add high EMI from motors and VFDs.

What environmental extremes—IP66/67 7, T4–T6, -40–+70°C—define suitability for tunnels, pipelines, and tank farms?

A phone can be certified for a zone and still be unusable in a tunnel. Water, cold, and vibration can kill uptime faster than the hazard itself.

Suitability for tunnels, pipelines, and tank farms is defined by sealing (IP66/67), surface temperature class (T4–T6), and ambient rating (often -40 to +70°C), plus corrosion, UV, and vibration readiness for the real mounting location.

IP66/67 and why it matters in real sites

IP66 is often the baseline for industrial wash-down. It protects against dust and strong water jets. IP67 adds temporary immersion protection. For tunnels and pipelines, water ingress often comes from condensation, wash-down, and heavy rain at portals. IP sealing is only real when:

-

the gasket compound stays elastic over years

-

the cover torque stays correct

-

the cable gland matches the cable outer diameter

-

the cable jacket does not soften or crack

Temperature class T4–T6 and what it means

T-class is about maximum surface temperature. It must match the ignition temperature limits of the site hazard. Higher numbers like T6 are stricter than T4. The phone must also remain functional at the ambient temperature range.

Conclusion

Explosion-proof telephones suit Zones 1/2 and 21/22, Class I Div 1/2 sites, and harsh offshore and refinery areas when certifications, groups, temperature class, IP sealing, and ambient ratings match the real installation.

Footnotes

-

Overview of the ATEX directive and IECEx zones for explosive atmospheres. ↩ ↩

-

Official IECEx resources for international certification of equipment in hazardous environments. ↩ ↩

-

Safety guidelines for managing dust hazards in agricultural and grain storage facilities. ↩ ↩

-

Technical standards for electrical equipment safety in North American classified locations. ↩ ↩

-

Understanding the risks and prevention of explosions caused by conductive dust particles. ↩ ↩

-

Research and technical data on the environmental challenges of offshore platforms. ↩ ↩

-

Explanation of the Ingress Protection code system for dust and water resistance. ↩ ↩