Dust looks harmless until it blocks audio ports and grinds into keypads. Then outdoor phones start to sound weak, or keys stop working.

For weatherproof telephone dust ingress ratings, the main standard to follow is IEC 60529 (IP Code). Use it to define IP5X (dust protected) or IP6X (dust-tight) and to run repeatable dust chamber tests.

A practical dust-testing roadmap for outdoor telephones

Weatherproof telephones 1 are not simple boxes. They have speaker and microphone paths, membranes, keypads, hooks, handset cords, and cable entries. Dust goes after every one of these areas. So a dust test should prove more than “the box looks sealed.” It should prove the phone still works and the dust does not reach sensitive areas in a harmful way.

Start with the right “family” of standards

IEC 60529 is the base reference for IP dust ratings 2. It gives you the test idea, the dust media, and the acceptance rules for IP5X and IP6X. If a project is tied to vehicles or automotive supply chains, ISO 20653 3 can show up because it adds “K” versions (like 5K and 6K). For most fixed outdoor emergency phones, IEC 60529 is still the clearest common language.

If the site is harsh in a different way, IEC 60529 may not be enough by itself. Windblown sand 4 can cut plastics and scratch coatings. That is more than “ingress.” In those cases, the tender can add a sand/dust blowing standard, but the IP dust rating still comes from IEC 60529.

Define the risk before picking IP5X or IP6X

A clean spec starts with a site story:

-

Is the phone near roads, mines, ports, or construction?

-

Do you have fine powder dust, or only large particles?

-

Will the unit be washed down after dusty work?

-

Is the phone expected to run for years with low maintenance?

The answers decide if “some dust is acceptable” (IP5X) or “no dust deposit inside” (IP6X) is the safer target.

Use acceptance rules that match a telephone, not just a box

For IP5X, dust ingress 5 is not fully prevented. …The key is that dust must not enter in a quantity that interferes with operation. For telephones, “operation” includes clear audio, stable keypad input, and reliable hookswitch or call button behavior. …For IP6X, the goal is dust-tight, which means no dust deposit inside the enclosure after the test.

A simple spec table that works in tenders

| Spec item | Good default wording | Why it protects your project |

|---|---|---|

| Dust test standard | “IEC 60529, dust ingress test for IP5X/IP6X” | One global reference for IP dust claims |

| Target level | “Minimum IP6X for outdoor dusty sites” | Avoids long-term dust buildup failures |

| Test configuration | “Test complete assembly with glands, caps, and membranes as installed” | Cable entry and vents decide the result |

| Acceptance | “No harmful dust ingress (IP5X) / No dust deposit inside (IP6X)” | Clear pass/fail language |

| Functional check | “Full call + keypad/button test before and after” | Keeps the rating tied to real use |

A clean dust plan makes the next questions easy, because everything else is just detail: which clause, which level, how long, and how to prep the enclosure.

The next section gets specific about the IEC 60529 clause that governs dust tests.

Which clause in IEC 60529 applies to dust tests I run?

Many teams say “tested to IEC 60529” but do not point to the dust clause. That makes vendor comparisons messy, because each supplier may assume a different method.

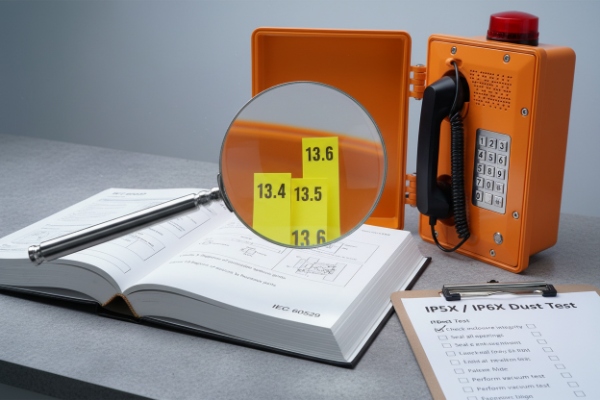

Dust ingress tests for IP5X and IP6X are defined under the IEC 60529 dust test clause (commonly referenced as Clause 13.4 for dust), while nearby clauses cover access probes and other first-digit checks.

What to write in your documents

For a weatherproof telephone tender, it helps to write the dust part like this:

- “Dust ingress: IP5X or IP6X in accordance with IEC 60529 dust test clause (dust test for first characteristic numeral 5/6).”

This wording matters because the first IP digit is linked to both:

1) protection against access to hazardous parts, and

2) protection against solid foreign objects.

Some test reports list multiple clauses for the first digit because the lab runs access probe checks and dust checks as a package. For your phone, you can keep the tender simple and focus on the dust ingress method and acceptance.

What the clause is trying to prove

Dust testing in IEC 60529 is meant to simulate fine dust exposure in a controlled cabinet. …The test uses a dust chamber with a defined dust media (often talcum powder 6) and a defined circulation method. The test can be done with or without a pressure difference, depending on the enclosure category. This matters for telephones because most outdoor phones are “closed” units with no fan-driven airflow, so they usually behave like a no-pressure-difference enclosure in the test.

How to avoid clause confusion with vendors

A quick way to keep bids comparable is to request:

-

the exact clause reference used for the dust test,

-

the enclosure category used (vacuum vs no vacuum approach),

-

…the duration and air extraction method (if vacuum is used),

-

photos of the dust setup and post-test internal inspection.

Table: clause-to-practice mapping for outdoor phones

| What you want to prove | What to request from supplier | What it prevents |

|---|---|---|

| True dust ingress rating | “IEC 60529 dust test for IP5X/IP6X (dust clause)” | “Marketing IP” without real test evidence |

| Correct test category | “State Category 1 or Category 2 method” | Wrong vacuum assumptions |

| Clear pass/fail | “IP5X: no harmful dust; IP6X: no dust deposit inside” | Debates during inspection |

| Telephone function holds | “Call audio + keypad/button test pre/post” | Rating that ignores real phone use |

Once the clause is clear, the bigger decision is the level: IP5X or IP6X. That choice should be driven by your environment, not by habit.

Do I need IP5X or IP6X for my environment?

Choosing the wrong dust level creates slow failures. The phone passes acceptance, then months later the audio gets weak or the call button starts to stick.

Use IP5X when some dust ingress is acceptable with no harmful effect, and use IP6X when you want dust-tight performance for outdoor dusty sites, low-maintenance deployments, or long service life targets.

What IP5X really means for a telephone

IP5X is “dust protected 7.” …Dust can get in, but not in a quantity that interferes with operation. For outdoor telephones, the risk is that fine dust collects on:

-

microphone membranes and speaker paths,

-

keypad domes and button guides,

-

hookswitch springs and plungers,

-

PCB areas where dust can hold moisture.

IP5X can work in controlled industrial zones, sheltered outdoor locations, or sites with planned cleaning. It can also work when the phone enclosure is well-designed and the acceptance criteria are tied to real function tests.

What IP6X changes in practice

IP6X is “dust-tight 8.” …The goal is no dust deposit inside after the test. This is the safer target for:

-

…roadsides and transport yards,

-

ports and coastal gates where dust mixes with salt,

-

mining and cement zones with fine powder,

-

…desert and dry-wind regions,

-

remote sites where maintenance visits are rare.

For a weatherproof emergency phone, IP6X also helps protect long-term audio quality. Dust inside the cavity can act like a blanket over the back of a speaker. It can also grind into mechanical parts during repeated button presses.

A practical environment guide

| Environment | Dust behavior | Better target |

|---|---|---|

| Indoor industrial, mild dust | Larger particles, lower exposure time | IP5X can be enough |

| Outdoor with traffic + wind | Fine dust, steady exposure | IP6X is safer |

| Mining, cement, quarry | Powder dust, heavy load | IP6X strongly preferred |

| Coastal logistics yards | Dust + salt mist | IP6X + corrosion spec |

| Remote solar / utility sites | Low service visits | IP6X to cut risk |

Simple client language

When clients ask why IP6X costs more, the clean answer is:

-

…“IP5X allows limited dust inside as long as it does not cause trouble.”

-

“IP6X aims for zero dust deposit inside after test, which protects long-term performance.”

After you pick IP5X or IP6X, the next question is duration. Many teams assume “8 hours always,” but IEC 60529 has more than one path depending on enclosure category and airflow.

How long should my dust test duration be?

A dust test that is too short gives false confidence. A dust test that is too harsh can become unrealistic, and it can punish seals in a way the real site never does.

In IEC 60529 dust testing, the common duration is up to 8 hours, with shorter duration possible when a defined air extraction rate is achieved in vacuum-based testing. Your exact duration depends on enclosure category and airflow.

…Understand the two enclosure categories used in practice

Many labs separate dust tests into two typical setups:

-

Category 1: the enclosure can be connected to a vacuum pump 9 because it can experience reduced internal pressure, or because the standard method calls for drawing air through it.

-

Category 2: no pressure difference is present relative to surrounding air, so the enclosure is tested in the dust chamber without vacuum connection.

For most weatherproof telephones, Category 2 is often the more realistic baseline because the phone is sealed and does not normally “breathe” large volumes of air during normal use. Still, if your design includes vents or if your customer requires vacuum-based testing, Category 1 may apply.

…How test duration is often determined

In vacuum-based tests, the goal is often described in terms of “how many enclosure volumes of air are drawn through” and the extraction rate. In practice, labs use:

-

a target air volume (often tied to enclosure volume),

-

a limit on depression (to avoid unrealistic stress),

-

and a maximum total time cap (commonly 8 hours).

Some test paths also allow a shorter test (often around 2 hours) when a defined extraction rate range is achieved. This is why two vendors can both claim “IEC 60529 IP6X” and still show different time lines in reports. …The key is that both must match the method and acceptance rules.

How to state duration in a tender without overcomplicating it

Instead of inventing your own hours, write:

- “Dust test duration and airflow per IEC 60529 method for IP5X/IP6X, including any category selection and extraction rate rules used by the lab.”

If you still want a hard number, use the common cap language:

- “Test continued until method endpoint is met or up to 8 hours, per IEC 60529.”

Table: duration choices tied to realistic phone risks

| Real site dust risk | How to set the test | Why this is fair |

|---|---|---|

| Mild dust, sheltered | IP5X method, standard duration per IEC 60529 | Matches low risk without over-testing |

| Continuous outdoor dust | IP6X method, full method endpoint up to 8h | Protects long service life |

| Remote site, low maintenance | IP6X + strict configuration control | Avoids long-term call failures |

| Design uses vents | Vacuum-based method as required | Dust can be pulled in through vents |

Once duration is defined, the last cause of failure is poor sample preparation. Dust tests do not forgive small assembly mistakes, and telephones have many small interfaces.

How do I prepare my enclosures before dust testing?

Most dust test “fails” are not design fails. They are build or setup fails. A missing blanking plug, a loose gland, or a twisted gasket can ruin an otherwise strong enclosure.

Prepare your weatherproof telephone exactly as it will be installed: same gaskets, same cable glands, same caps, same vent parts, and the same closing torque. Then document every opening and every plug before the chamber door closes.

Treat the tested unit as a full system

For weatherproof telephones, the dust path is often not the main cover seam. It is the “small stuff”:

-

RJ45 entry and cable gland 10

-

unused knockouts

-

handset cord exit

-

keypad frame seal

-

speaker and microphone membrane bonding edge

-

tamper screw seats and washers

-

rear mounting plate interface

So preparation must lock down all of these parts in the same way production does.

A step-by-step prep routine that reduces surprises

1) Build with production parts

Use final gaskets, final adhesives, final membranes, and final screws. Avoid “handmade” sealing that will not exist in production.

2) Install the real cable entry solution

If the phone uses a gland, install it and torque it to the assembly spec. If the product can be installed with conduit, test it with the same conduit adapter method used on site.

3) Close and torque using a recorded method

Use the actual tightening sequence and torque values. Record the torque. Many seal issues come from uneven compression on a rectangular gasket.

4) Plug what is normally plugged

If an opening is normally closed by a cap, keep it closed. If a drain hole is normally open in service, leave it open, because the rating must reflect real use.

5) Pre-test functional check and baseline photos

Place a call, check audio level, press buttons, and record results. Take photos of all seals and entries. These records make root-cause work faster if something fails.

6) Post-test handling rules

Do not blow compressed air into seams after the test. That can push dust deeper. Open the unit in a clean area, and inspect slowly so dust patterns are not disturbed.

Table: common prep mistakes and how to prevent them

| Mistake | What happens | Prevention |

|---|---|---|

| Testing without real glands | Dust enters through cable path | Test with final gland and cable method |

| Uneven screw torque | Local gasket gaps | Use torque spec + tightening sequence |

| Missing blanking plug | Dust deposit near PCB | Plug all unused holes as in install |

| Wrong membrane or adhesive | Dust behind speaker path | Use production membrane and bonding process |

| Different mounting orientation | New dust paths appear | Mount in normal operating position |

A well-prepared sample makes the dust test meaningful. It also makes your IP claim easier to defend in a tender, because you can prove the rating matches the installed product, not a lab-only setup.

Conclusion

Use IEC 60529 for IP dust ratings, point to the dust clause for IP5X/IP6X, pick the level from your site dust risk, follow the standard duration endpoint rules, and test the phone as a complete installed assembly.

Footnotes

-

Durable communication devices designed to withstand harsh outdoor environments and particle ingress. [↩] ↩

-

Global standard classifying the degrees of protection provided by enclosures against intrusion. [↩] ↩

-

Standard defining protection degrees for road vehicle electrical equipment against foreign objects. [↩] ↩

-

A specific environmental test simulating abrasive sand particles driven by high-speed wind. [↩] ↩

-

The infiltration of solid particles into an enclosure, potentially causing mechanical failure. [↩] ↩

-

Fine powder used in testing to simulate dust exposure for IP rating certification. [↩] ↩

-

Designation indicating limited dust entry is permitted without interfering with device operation. [↩] ↩

-

Highest dust protection rating ensuring no particles enter the enclosure under vacuum. [↩] ↩

-

Equipment used to create negative pressure inside enclosures during Category 1 dust testing. [↩] ↩

-

Mechanical device securing cable ends to equipment while maintaining enclosure sealing integrity. [↩] ↩